In Situ Manufacturing: Pipe Relining in Demanding, Corrosive Environments

Onsite technology offers continuous manufacture and insertion of new high-performance pipe, without excavation and replacement.

The idea is not a new one: Use composites to reline underground pipe without the time, effort, and expense of digging up all that dirt. Currently, there are two types of lining technology. One is a premade, precatalyzed but uncured (and therefore still flexible) composite sleeve, typically delivered to the site flat and folded for ease of transport. The sleeve is pushed through the existing pipe with hot water, which inflates and then cures the liner. The other uses a cured pipe, smaller in diameter than the existing pipe, which is delivered to the site in sections or (if small enough in diameter) coiled in long lengths. The new pipe is inserted and then secured in place by grout that is pumped in between the old and new pipe. Such “in situ” systems have sufficed for relining low-pressure water or sewer lines, but when it comes to replacing high-pressure gas, oil and industrial pipe in more demanding or corrosive environments, excavation has been the best option. That, however, is changing, thanks to a new pipe relining system that integrates a first-of-its-kind onsite production method. It employs a computer-controlled, continuous manufacturing and installation process, featuring complex, multistage tape-winding machinery that eventually will be able to reline up to 10 miles/16 km of existing high-pressure pipeline from a single entry point.

The company and the product behind this technology are both called Smart Pipe. The Houston, Texas-based company’s method is the sketch-on-a-napkin brainchild of a group led by Smart Pipe CEO Steve Catha, who first conceived of the idea in 1993. The concept sat idle for several years until 2002, when development funding was procured. Earnest development and proving of the technology began in 2004.

To date, Smart Pipe has performed one installation, relining a 60-year-old, 700-ft/213.4m section of hot-water pipeline with an inside diameter of 12.39-inch/314.7-mm, which had been corroded over the years by heat and water impurities at a chemical plant in the northeastern U.S. Because of the relatively short distance involved in this application, pipe production actually took place at a Smart Pipe facility in Abita Springs, La. Pipe fabrication, however, took place outdoors, just as it would if done on site: A temporary manufacturing tent, measuring 500-ft long, 25-ft wide and 15-ft tall (152m by 7.6m by 4.6m), was used to protect the process and control systems from the elements. The finished pipe was coiled and transported by truck to the worksite for installation. William Stringfellow, an appli-cations consultant to Smart Pipe, says that up to 2,000 ft/610m of continuous HDPE-lined Smart Pipe with a diameter of 6 inches/152.4 mm can be transported by this method. Installation was accomplished over a period of two-and-a-half 12-hour days, with the actual pulling of pipe consuming just three hours.

Smart Pipe COO Kyle Bethel and Stringfellow, as well as the client, report that the new pipeline passed all tests and functions as promised. Indeed, Smart Pipe lists several benefits to be derived from its manufacturing and installation system: A service life of 40 to 50 years, depending on application and environment, and a Hazen-Williams co-efficient (water friction loss) of 75 to 80 — compared to 150 for steel — which means that the new pipe, even though smaller in diameter, can move water more efficiently than the host pipe. Moreover, the system is compliant with the American Petroleum Institute’s API 15S “Qualification of Spoolable Composite Pipe” and meets U.S. Department of Transportation (DoT) requirements for Class 3 and Class 4 lines (close proximity to humans). Most important, the Smart Pipe method can restore a DoT Class 3 or 4 host pipe to full pressure and service ratings at about 50 percent of the cost required to excavate and replace the existing pipeline using traditional methods.

Multiphase, inline process

The Smart Pipe process, whether pipe is constructed on or off site, is continuous and integrates a variety of processes and composite materials that prepare the new pipe for insertion into the host pipe (the pipe to be relined). At the worksite, excavation is required only to expose each end of the host pipe. At one end, equipment and computer control systems are put in place to help pull the new pipe through the host pipe. At the other end, Smart Pipe’s portable process prepares the pipe liner for insertion. Although the pipe coatings and wrap materials can vary, the pipeline in question was re-lined as follows, working from the inside out (see figure, p. 38).

The liner. The process began with 40-ft to 50-ft (12.2m to 15.2m) sections of standard PE 100, a high-density polyethylene (HDPE) pipe chosen for the liner. Stringfellow says that PE 100 is expected to be the choice in most cases, although other material types (PEX, PA-11 or PVDF) might be used if temperature or corrosion factors dictate.

Extruded PE 100 is supplied to Smart Pipe by a third party. Liner diameter depends on the diameter of the host pipe, but for this first job was 12 inches/305 mm. Similarly, liner wall thickness depends on the application and environment. In this case, conditions dictated a thickness of 0.16 inch/4 mm. The quantity of HDPE pipe required for a given project depends on the total length of the host pipe; Stringfellow says this can range from a few hundred feet to 10 miles, although Smart Pipe is currently targeting applications of 2 miles to 2.5 miles (3.2 km to 4 km) in length: “Longer is better for us,” says Bethel, noting that Smart Pipe’s efficiencies are enhanced as the distance increases.

The liner sections first are brought together in the assembly line and, as the process continues, are butt-fusion welded, end to end, using a TracStar fusion machine provided by McElroy Mfg. Inc. (Tulsa, Okla.). This process is followed immediately by an inline ultrasonic welding inspection process that moves with the pipe along the production line to verify a leak-proof seal.

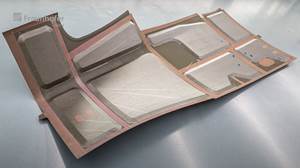

Fabric sleeves. Next, two layers of a high-strength fabric material, about 6 inches/152 mm wide, are wrapped around the pipe using two concentric tape winders custom-designed for this application and controlled by an in-house-developed computer system. Positive and negative wind angles (+/-65°) are used.

Although Bethel reports that wraps manufactured by any other suppliers can be used — “We are fully flexible on all the fibers we use” — Smart Pipe favors wraps made of Spectra, a high-modulus, high-strength polyethylene fiber created via a patented gel-spinning process by Honeywell Advanced Fibers and Composites (Colonial Heights, Va.). The Spectra-based material (Spectra is a registered trademark of Honeywell International Inc.) was chosen for its high strength-to-weight ratio, low moisture uptake, resistance to chemicals and ultraviolet light, and its ability to provide the required structural and pressure support without adding a great deal of weight. Honeywell delivers the fibers to Hexcel (Dublin, Calif.), where they are converted into a basket-weave fabric. A third party, JHRG LLC (Spring Hope, N.C.), adds to the fabric a film of heat-set ethylene vinyl acetate (EVA); the EVA prevents the fabric from unraveling and slipping before it is wound around the HDPE liner.

Carbon fiber pulling tape. At the next station, four continuous carbon/thermoplastic “pulling tapes” are applied axially. Spaced at equidistant intervals on the pipe circumference, they provide the means by which the new pipe is pulled through the host pipe. The tapes are flattened, triaxially braided sleeves, 1 inch to 3 inches (25.4 mm to 76.2 mm) in width, that run the length of the pipe on the 0° axis, where strength is most needed during installation. (Details on pulling and installation technology are discussed below.) The 50K, 34-550 carbon fiber braid, brand-named Trimax, is provided by A&P Technology Inc. (Cincinnati, Ohio) precoated with a thermoplastic resin. As the tape is applied, the material is essentially ironed in place, and the heated thermoplastic wets out the fibers.

Fiber-optic sensors. Alongside the pulling tapes, technicians attach strips of encapsulated fiber-optic sensors that also run the entire length of the pipe. In many ways, it’s these sensors, and the technology behind them, that enabled the Smart Pipe concept to make the leap from concept to reality. “The thing that came along to help make this work was the acceptance of fiber optics as a monitoring system,” contends Bethel, adding that the sensors have a dual function: During pipe installation, they provide data on pipe tension and, integrated with the pipe-pulling system, permit on-the-fly tension adjustment. After installation, the sensors can (within 3.1 ft/1m) detect leaks, sense displacement and report temperature along the pipe, all of which helps the pipeline manager monitor pipe integrity and anticipate potential failures.

Glass fiber wraps. Next in the assembly line is the winding of E-glass fiber tows provided by Fiber Glass Industries Inc. (Amsterdam, N.Y.). Like the Spectra fiber-based layers, bands up to 36 tows wide are wound at alternating angles (+/-65°). Stringfellow says the material is typically standard E-glass. These tows are applied primarily to secure the carbon fiber tape and the fiber-optic lines and are designed to provide only minimal pressure support.

Pipe deformation for insertion. In the next step of the manufacturing process — possibly the most creative and innovative — the pipe is deformed into a “C” shape to temporarily reduce its diameter by about 40 percent so that it will fit in the host pipe. The deformation device, (see Step 5, p. 37) designed and constructed entirely by Smart Pipe, applies a force on the pipe adequate to change its shape without permanently deforming or damaging the liner. “Extensive FEA was used to determine deformation forces, and that analysis was used to design the machine,” says Bethel. The pipe moves through this deformation process at a rate of 4 ft/min (1.2m/min), which provides up to 1 mile/1.6 km of pipe daily. Currently the slowest of the manufacturing steps, deformation ultimately dictates the speed of the overall manufacturing system.

Mylar wrap to maintain deformation. Immediately following deformation, the pipe is quickly wrapped with Mylar tape, a 0.08-inch/2-mm thick polyester film produced by DuPont Teijin Films (Hopewell, Va.). The Mylar tape’s only function is to hold the “C” shape long enough for pipe installation.

Protective outer wrap. Finally, just before it enters the host pipe, a thin sleeve of HDPE film is wrapped around the whole pipe. This casing consists of an HDPE carrier and a partially cured butyl rubber adhesive. It acts primarily to protect the pipe during installation and is supplied by Industrial Polymers (Houston, Texas).

Push/pull pipe installation

As completed pipe liner comes off the end of the assembly line — or, in this case, is delivered to the work site — it’s ready to enter the host pipe. Before insertion, Stringfellow says a 20-ft/6.1m section of standard HDPE pipe is pulled through the full length of host pipe to verify that there are no impassable obstacles and to make sure that the new pipe can negotiate all turns or other changes in direction. “We can make bends, including 90° bends, so long as the bend radius is not too sharp,” reports Stringfellow.

As sophisticated as the pipe assembly process is, the pipe pulling system might be the most complicated and highly engineered aspect of the Smart Pipe manufacturing process. The primary challenge, says Bethel, is to match the speed of the pipe puller with the speed of the assembly line, accounting along the way for host pipe friction and overall tension along the length of the new pipe. This demands a level of coordination between assembly line, pipe and puller that is as much a feat of software engineering as it is physical engineering. “We spent a full year in design before we built anything,” reports Bethel.

The insertion process starts at the terminus of the host pipe. Here, a Plasma rope — woven by Puget Sound Rope (Anacortes, Wash.) from high-strength, plasma-treated Spectra 12-strand fibers — is attached to a pipeline “pig,” a lightweight bullet-shaped foam cylinder, which is blown via air or water through the host pipe toward the pipe insertion point. Once delivered, the Plasma rope is woven via the long-splice method (common in fishing, says Stringfellow) to the four carbon fiber tapes extending from the end of the new pipe. Pulling then begins.

At the terminus of the host pipe, a 35-ft/10.7m wide spool traversing on a 60-ft/18.3m trailer winds and pulls the Plasma rope, dragging behind it the new pipe. The traction winch that pulls the rope is rated to pull up to 500,000 lb (about 227,800 kg). The take-up winch is rated to pull up to 35,000 lb/15,876 kg. Both of these winches are computer controlled and their speed is modulated to match production line speed. Stringfellow says this system can pull a total pipe weight of up to 300,000 lb (about 136,000 kg), which Smart Pipe says is more than adequate to meet the needs of almost any application it expects to encounter.

Once the end of the new pipe reaches the end of the host pipe, pulling and production are stopped. Excess pipe is cut to length and, after a couple hours of rest to allow the new pipe to settle in the host, the new pipe is sealed at both ends and pressurized air is introduced. According to Bethel and Stringfellow, only 10 psi to 15 psi (0.69 bar to 1.03 bar) pressure is required to overcome resistance from the Mylar wrap and reform the new pipe from “C” shape to full round. While the pipe is still sealed, a full hydrostatic test at operational pressure is performed to verify pipe integrity and to test fiber-optic sensor function.

After all tests are complete and the new pipe is deemed functional, the pipe ends are unsealed and nippled to the host pipe and the relined section is ready to reconnect to the larger system and resume operation.

The leap from feet to miles

With this initial and relatively short pipeline replacement behind it, Smart Pipe is negotiating new projects that run up to 2.5 miles/4 km in length. Stringfellow says the challenge in “selling” the Smart Pipe concept is two-fold: Applications the company targets typically have multiple layers of governmental and corporate oversight that must be educated on the technology — “We have to sell a project several times,” he says — and the uniqueness of the technology means potential clients have much built-in skepticism to overcome.

The company, however, has its sights set high. The ability to economically and quickly reline pipelines that previously required replacement means that Smart Pipe technology should enjoy heavy use.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreOptimizing AFP for complex-cored CFRP fuselage

Automated process cuts emissions, waste and cost for lightweight RACER helicopter side shells.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

Modeling and characterization of crushable composite structures

How the predictive tool “CZone” is applied to simulate the axial crushing response of composites, providing valuable insights into their use for motorsport applications.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

Read More