Inside manufacturing: Dual-Laminate Pipe Comes of Age

Computerized pipe fusion and customized multimandrel filament winding equipment mass-produces nearly four miles of pipe for chemical plant in China.

Thermoplastics have been valued for their inherent corrosion resistance for more than half a century. Extruded and thermoformed easily, thermoplastic shapes can be welded together in complex configurations to eliminate potential problems with mechanical joints. However, the mechanical properties of the neat resins are insufficient to bear structural loads in demanding applications, such as large tanks and pipe.

To make thermoplastics practical for pipe installations, they were adopted, early on, as lining materials for traditional and relatively inexpensive steel pipe. The liner protected the steel from the corrosive effects of chemicals while the steel provided the structural strength and stiffness to support the thermoplastic. This solution, however, was not without its problems. Tensile and flexural modulus are low for most thermoplastics and, because thermoplastics creep, these properties diminish over time as the material is exposed to operating stress. If a thermoplastic liner cannot be adequately bonded to the exterior pipe material, such as steel, then creep and high thermal contraction/expansion can lead to mechanical failure of the lining. In addition, the steel exterior is still vulnerable to corrosion and is also heavy, increasing shipping and handling costs.

Conventional anticorrosive alternatives — stainless steel and titanium — have sufficient strength and are effective against corrosion, but are much more expensive. Stainless steel (a steel/chromium alloy) was, in fact, invented for corrosion-resistant applications. Its chromium content (from 10 to 26 percent) is reactive, and forms a passivation layer — a thin film — of chromium oxide (Cr2O3), which is highly resistance to acidic corrosion. It is not immune to corrosion, however, when exposed to strong acids. For that reason, stainless steel pipe designers rely on known data to determine the steel’s required chromium content, predict a particular pipe’s useful life and establish replacement dates. Titanium, with 60 percent less density than steel (hence, less weight), forms a more effective oxide film, but is still susceptible to pitting and general erosion when exposed to organic chlorides, wet chlorine and/or seawater at elevated temperatures.

When isophthalic polyester thermosetting resins were developed (circa. 1960), their anticorrosive properties (contributed by the oxidizing properties of isophthalic acid) fueled the introduction of fiberglass composites in the anticorrosion market. In particular, they replaced rust-prone steel in underground gasoline storage tanks. Today, a wide range of products, from piping to cooling towers, are manufactured from glass fiber-reinforced isopolyesters and epoxy vinyl esters, which are resistant to both acidic and alkali environments.

Winning a Place in the Market

Against that backdrop, dual-laminate technology was developed. CPF Dualam Inc. (Montreal, Canada) was the first to use this technology, in 1957. In the last 40 years, the company has played a leading role in making dual laminate products available in industrial processes that require the handling of highly corrosive materials. In 2002, CPF Dualam merged with Prolite Plastics (Port Coquitlam, British Columbia, Canada), which was renamed CPF Dualam Vancouver. The move combined CPF Dualam’s expertise in the dual-laminated pressure vessel market with Prolite’s knowledge of dual-laminate pipe manufacturing.

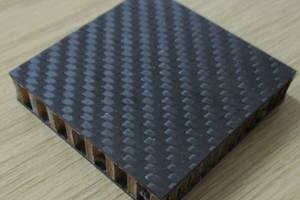

Dual laminate refers to a method of construction that permits a pipe fabricator to combine a thermoplastic liner material with a fiber-reinforced thermoset composite to make a structure with high strength-to-weight but broader corrosion resistance, less tendency to crack during handling and installation and greater resistance to brittle fracture at low temperatures than FRP alone. Although dual laminates historically have required a more costly manufacturing process than fiberglass, Guyle McCuaig, vice president of CPF Dualam Vancouver maintains that the premium price is justified by the lengthier service life and reduced maintenance cost. Further, the liner effectively isolates the pipe’s fiber reinforcement from potential contact with corrosive chemicals.

“We are competing with titanium and stainless steel in the critical service industry for severe corrosion,” says McCuaig, noting that dual-laminate pipe is lighter than comparable titanium pipe and comes in at about half the cost. Unlike lined steel, dual laminates will not externally corrode and, according to the company’s calculations, weigh 75 percent less.

The company can custom fabricate pipe (to 48 inch/122 cm diameter), cylindrical tanks and self-supporting stacks and cooling towers, using liners made from polyvinyl chloride (PVC), polypropylene (PP), chlorinated polyvinyl chloride (CPVC), polyvinylidene fluoride (PVDF), ethylene chlorotrifluoroethlyene (ECTFE) and perfluoroalkoxy (PFA). The resulting products can replace more expensive metal alloys, lined steel and unlined FRP in many high-risk applications, including chlor-akali (tanks, cooling towers) pulp bleach plants (tanks, ClO2 generators), environment protection (gas scrubbers) and containment and piping systems for chemicals used in metal refining and fertilizer manufacturing.

Moving Toward Mass Production

Until recently, the one drawback to the dual-laminate manufacturing process, according to CPF Dualam, was that most pipe sections have been manufactured on single-spindle filament winding equipment. For that reason, most dual-laminate pipe fabricators reach maximum production capacity at between 200 ft and 500 ft (60.9m and 152.4m) per day.

That changed for CPF Dualam in 2005, when major polyurethane manufacturers BASF AG (Ludwigshafen, Germany) and Huntsman Polyurethanes (Auburn Hills, Mich.) contracted with the Vancouver division in 2005 to design and fabricate 25,000 linear ft (10 km) of pipe for the new BASF-SBPC Chemical Complex in Shanghai, China — now the world’s largest manufacturer of a key polyurethane component, toluene diisocyanate. A complicating factor was the lengthier shipping time the company had to factor in for the project, because unusual commercial regulations in mainland China frequently delay arrivals, notes McCuaig. Therefore, the project needed a quick stateside turnaround.

To meet the schedule at the Vancouver plant’s 30,000 ft² (2,787m²) facility, the company invested in a multimandrel filament winding machine that can wind up to eight lengths of pipe simultaneously. Built by filament winding equipment specialist McClean Anderson (Schofield, Wis.), the machine is capable of winding 48-inch/1.2m diameter pipe in sections as long as 20 ft/6.1m. The machine, according to McCuaig, vastly reduces production time and, together with the company’s automated methods for liner-to-pipe bonding and butt fusion of pipe sections, now produces lightweight pipe as reliable and cost effective as plastic lined steel or FRP offerings.

Streamlining a Complex Process

The pipe for the BASF facility was designed, stress-test analyzed and manufactured to DIN 16965 Type B, the German standard for dual-laminated pipe, at the Vancouver facility over a five-month period. In an effort to meet the needs of two different corrosive services, the Vancouver team determined that the liners should be made primarily of polypropylene (PP) and polyethylene (PE-100 European grade), for which CPF Dualam Vancouver relied on a European source, Georg Fischer Deka (Dautphetal-Mornshausen, Germany). PP and PE are popular choices for dual-laminate liners because they exhibit not only high chemical resistance but also good abrasion resistance. PP is resistant to sulfuric acid, nitric acid, hydrochloric acid, caustic soda and other reagents. One of the more inert materials on earth, PE is extremely resistant to a range of chemicals and water/saltwater corrosion. More specifically, PE can be used in severe chemical environments because of its resistance to virtually all inorganic chemicals (excluding strong oxidizing agents and free chlorine) and most organic compounds (except strong or chlorinated solvents). Unlike metals, both PP and PE are nonconductive and, therefore, not subject to electrochemical/galvanic corrosion.

CPF Dualam’s Engineering Dept. created sketches for initial visualizations and concepts, and then used CAEPE pipe stress analysis software supplied by SST Systems Inc. (San Jose, Calif.) for structural calculations. AutoCAD software (Autodesk, San Rafael, Calif.) was used to generate fabrication drawings as well as piping isometric or process-and-instrumentation diagrams. Finite element analyses were performed using properties from Trilam software.

Careful attention in the design stage is given to both the liner thickness and the strength of the liner/FRP bond. The liner thickness must be sufficient to resist potential permeation, but liners thicker than 3/16-inch tend to increase undesirable interfacial sheer stress between the liner and reinforcement.

The first step in the production process is liner fabrication. Liners are formed from flat sheet stock into cylindrical shape, and then seams are fused over a mandrel via hot gas welding (see Step 1, at left). Where other dual laminate fabricators fuse thermoplastics using manual methods, CPF Dualam has developed a computerized servomechanical fusion technique to speed the process, which employs a coated heating plate and careful control of temperature, pressure and movement.

To allow for spark testing or installation of the liner leak detection system, a layer of electrically conductive material is laminated right behind the thermoplastic. Then, a secondary corrosion barrier is laminated using corrosion-resistant thermoset vinyl ester resins, surface veils and glass chopped strand mat. This step is put in as a backup system in the unlikely event that the thermoplastic liner is damaged, according to CPF Dualam.

Dual-laminate fabricators encounter the same challenges faced by fabricators of lined steel. In a dual laminate structure, the thermoplastic liner tends to expand and contract at a greater rate than the outer thermoset reinforcement due to the difference in coefficient of thermal expansion (CTE). CPF Dualam’s bonding method ensures a mechanical or chemical lock with the pipe’s FRP component, to minimize this expansion differential, thus preventing concentration of stresses that could cause mechanical damage. This bonding process begins by melt embedding a layer of dry woven glass fabric to the liner — literally embedding it into the outside diameter of the extruded liner to a depth of 50 percent of the thickness. The embedded glass reinforcement lends the liner greater stability (which resists creep and thermal expansion/contraction) and also provides a secure surface to which to bond the external FRP casing. The Vancouver-based team carried out the melt-embedding process with its custom-built, computer-controlled embedding machine.

The liner/FRP casing bond reportedly enhances the thermoplastics’ temperature- and pressure-handling capabilities. Pipes installed in corrosive environments generally have low-pressure requirements (less than 150 psi/10 bar), according to McCuaig, who notes that temperature requirements can reach 100°C/212°F. A polypropylene liner alone, for example, has a maximum service temperature of 90°C/195°F, but in dual-laminate format, its service temperature goes up to 95°C/205°F, providing a greater margin of safety.

Once the liner is embedded with the glass fabric, it is mounted on a spindle in the multimandrel filament winder. “We filament wind an epoxy vinyl ester with E-glass winding strands for strength,” McCuaig explains. CPF Dualam used Derakane 411 resin, supplied by Ashland Performance Materials, Composite Polymers (Dublin, Ohio). The bispehnol-A epoxy vinyl ester resin has (at 25°C/77°F) a density of 1.046 g/ml and a dynamic viscosity of 370 MPa. According to Ashland, it also exhibits high resistance to a wide range of acids, alkalis, bleaches and solvents, as well as seawater and salt air — an important factor because Shanghai is one of China’s major seaports and the BASF factory is adjacent to the bay front.

Pipes for this project ranged in diameter from 1 inch to 24 inches (25.4 mm to 609.6 mm), with wall thicknesses calculated using pipe span, pressure rating and temperature. The pipe then heads to the spooling (Dualam’s term for pipe joining) facility where the company uses its servo-mechanical pipe butt fusion technique to join sections of pipe into complex configurations (see, for instance, Step 4, p. 3). Pipe joints and mitered joints are created and bends and mechanical joint fixtures are added to filament wound straights, using the automated welding process, and then joints are overwrapped with FRP outer layers. The curved sections are not wound, but rather the company uses a custom contact molding method, McCuaig says. At this stage, an exterior finish is typically applied to promote corrosion resistance — in this case, an ultraviolet (UV) resistant and flame retardant gel coat.

Finished pipe sections were shipped by sea in 40 ft/12.2m containers to Shanghai. A technical team from CPF Dualam Vancouver went to Shanghai to oversee the installation of the pipe by local workers who welded the PE and PP liners using pipe fusion techniques and then overwrapped the joints using fiberglass laminating kits provided by CPF Dualam (see photo at right). Despite the language barrier — McCuaig notes that one of the biggest challenges on the installation side of the project was simply communication — the installation was completed in about five months.

Big Jobs on the Horizon

The BASF Shanghai project has opened doors: CPF Dualam is working on another 25,000-linear ft installation, this time for PPG Industries-Industrial Chemicals in Lake Charles, La., and has several other large projects in the works.

Because its jobs extend to more than 25 countries, the company has set up pipe spooling shops around the world to speed project completion. “We intend to manufacture the dual-laminated pipe products in Vancouver and then feed assembly and installation to these local facilities,” says McCuaig. In addition to its main pipe plant at its headquarters in Vancouver, the company maintains two plants in Montreal, two in Louisiana and one facility each in New York, Texas, Ontario (Canada) and Corazal, Belize. Currently, the company is building a tenth facility in Shantou, China.

One of the biggest hurdles facing the sector today, from McCuaig’s point of view, is the lack of standards for dual laminate piping. “We have to prove our product every time,” he says. “We have done our own third-party testing and hope for a standard in North America in the next five to 10 years,” he says. A written standard is now available for dual-laminated vessels, and piping is a natural extension of that, according to McCuaig.

Related Content

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MorePro-Set named official materials supplier for New York Yacht Club American Magic

Competitive sailing team prepares for the 37th America’s Cup beginning in August 2024 with adhesives, resins and laminate testing services for its AC75 monohull construction.

Read MorePark Aerospace launches aerospace, MRO structural film adhesive

Aeroadhere FAE-350-1 is a curing epoxy formulation designed for composite, metal, honeycomb and hybrid applications.

Read MorePRF Composite Materials introduces primer, adhesive films

Novel RFA570 eXpress cure adhesive film and RF Primer are compatible with PRF’s full range of epoxy prepregs formulations.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More