Integrated drop-in-place superstructure the solution for Eight Mile Bridge

Based on the successful performance of previous composite bridge decks installed in Hamilton County, Ohio, highway engineers recently took a bold step, specifying an integrated composite bridge superstructure — that is, deck and support beams together in one unit — to replace a deficient span known as Eight Mile Bridge.

Based on the successful performance of previous composite bridge decks installed in Hamilton County, Ohio, highway engineers recently took a bold step, specifying an integrated composite bridge superstructure — that is, deck and support beams together in one unit — to replace a deficient span known as Eight Mile Bridge. In particular, they wanted to avoid the horizontal joints of previous designs, in which a composite deck is affixed to steel or concrete girders or beams, using adhesives, stirrups or other hybrid methods. “Typically, failure or structural issues occur where materials are joined together,” explains Hamilton County engineer Steve Mary, “A drop-in-place integral system eliminates joints between deck and beams — it’s the logical next step.”

The county selected an integral FRP superstructure concept developed by Composite Advantage (CA, Dayton, Ohio) for the 62-ft/19m-wide, two-lane crossing. While the span was only 22 ft/6.8m, the bridge had to meet American Assn. of State Highway and Transportation Officials (AASHTO) HS 20 loading (alternative military truck loading) and L/800 deflection criteria. Further, it had to have a 13° skew angle (so the superstructure is not built at right angles, but as a trapezoid), and it had to accept an asphalt wear surface.

To meet these criteria, CA designed eight vacuum-infused sandwich structures, 22 ft/6.8m long and slightly less than 8 ft/2.4m wide. On each panel, the 6-inch/152-mm-thick flat deck is made from trademarked TYCOR fiber-reinforced core, which comprises long “sticks” or machined lengths of closed-cell foam core that are wrapped with fiberglass rovings and scrim cloth. Supplied by WebCore Technologies Inc. (Miamisburg, Ohio), the wrapped core structures were similar to those used in previous CA bridge designs (see “Learn More,” at right). The thickness, density, number of roving wraps and dimension of the foam elements were custom-designed to meet the crush and shear loads on the deck, says CA. Laminated to the underside of the deck are tapered vertical beams, about 15.75 inches/400 mm deep and spaced approximately 30 inches/762 mm on center running the length of the panels in the span direction (see photos). These are filled with unreinforced foam manufactured by Elliott Co. of Indianapolis Inc. (Indianapolis, Ind.). A 0.5-inch/12.5-mm-thick skin reinforced with multiaxial fiberglass fabric supplied by V2 Composites Inc. (Auburn, Ala.) and Vectorply Corp. (Phenix City, Ala.) is wrapped around the entire panel, deck and beams, and, in effect, forms the shear webs for the beams. Extra multiaxial material at each beam base acts as a beam cap or flange.

Each panel/beam structure was fabricated and infused as a unit, using vinyl ester resin from Ashland Inc. (Dublin, Ohio), in CA’s proprietary resin infusion process. The resin is pigmented with a dark gray color, with UV inhibitor added. To connect the structures and expedite assembly at the job site, an additional “joint beam” was bonded and bolted at one edge of each part to form a shelf for the adjacent part. CA conducted extensive testing at the National Composite Center (Kettering, Ohio) to validate the design. Additionally, a full-scale structure was subjected to static bending, shear and fatigue tests involving 2 million cycles.

CA delivered eight deck/beam structures to prime contractor Trend Construction Co. (Cincinnati, Ohio) at the job site. They were dropped, in sequence, onto the new abutments in less than one day, using an excavator already at the site as a crane. As each was fitted to its neighbor, Magnobond 56 adhesive, supplied by Magnolia Plastics Inc. (Chamblee, Ga.), was applied to the joints to fill voids; an overlay strip of chopped glass strand mat and adhesive was placed over each joint and multiple tie straps were bolted across each one to help prevent panel movement that might crack the wear surface, which is the design’s only potential maintenance issue, says CA’s president Scott Reeve.

Horizontal rebar was inserted into predrilled holes in the beams and tied with vertical rebar loops by Rod-Techs Inc. (Cincinnati, Ohio). Formwork then was erected around the abutment and superplastic (high-flow) concrete was poured through holes cored in the deck to form a diaphragm that securely ties the panels to the abutments. Application of the wear surface followed, and the bridge was ready for traffic within days, says Mary, shortening road-closure time.

Related Content

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreGKN Aerospace, Joby Aviation sign aerostructures agreement

GKN Aerospace will manufacture thermoplastic composite flight control surfaces for Joby’s all-electric, four-passenger, composites-intensive ride-sharing aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreRead Next

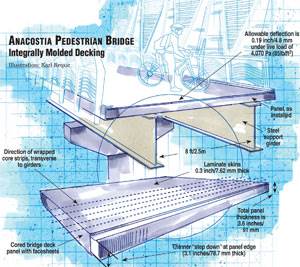

Engineering Insights: Pedestrian Bridge Makes Case for Composites

Infusion molded deck incorporates high-performance core, which facilitates fast processing.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)