JEC Americas 2014 Review

Composites industry exhibitors at this combined show emphasized the textile side of the fiber/resin mix and touted process automation.

JEC Americas 2014 (May 13-15) took place in the Georgia World Congress Center (Atlanta, Ga.), colocated with the textile industry trade shows Techtextil North America and Texprocess Americas. JEC says the three shows will continue to colocate through 2016 — JEC Americas will be held June 3-5, 2015 in Houston, Texas and return to Atlanta for the first week of May in 2016. Although composites exhibitors occupied only about eight of the combined show’s display aisles, HPC found the following new developments and evidence of several key trends, particularly in 3-D textiles and automation. (For a sampling of new technologies that made their debut at the show, see entries under "Products & Literature" on the HPC July 2014 issue Home Page.)

Broad themes

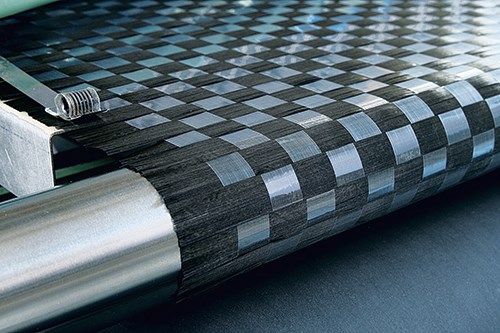

The use of 3-D textiles for reinforcement of composites was the focus at several booths. Automation, robotics and textile equipment specialist Stäubli (Pfäffikon, Switzerland and Duncan, S.C.) underlined the role its 3-D weaving technologies have played in production of composite structures for CFM International’s (Evry, France and Cincinnati, Ohio) LEAP jet engine, which powers the latest single-aisle commercial jetliners. Also on hand was Lindauer DORNIER GmbH (Lindau, Germany), which, as part of Dassault/Dornier in 1973, produced the Alpha Jet, reportedly the first high-performance aircraft with series-production structural components made from carbon fiber composites. No longer an aircraft parts fabricator, DORNIER now focuses on fabric weaving technology and equipment. And Sigmatex (UK) Ltd. (Cheshire, U.K. and Benicia, Calif.) also highlighted new and specialized 3-D capabilities. All three companies touted the nearly endless possibilities available now, including very localized, tailored fabric architectures.

Increasing manufacturing speed and efficiency through automation was another prevalent theme. Show attendees were exposed to new automated fiber placement (AFP) and automated tape laying (ATL) equipment designed to capture the benefits of both processes, as well as robotic work cells, such as the system demonstrated live by automation specialist KSL Keilmann (Lorsch, Germany). A video highlighting the company’s extensive work in composites included segments devoted to a preforming center for the Eurocopter (Donauwörth, Germany) NH90 helicopter’s fuselage frame profile; a CNC production unit for the Airbus (Toulouse, France) A380 jumbo jet’s pressure bulkhead; and robotic sewing units for The Boeing Co.’s (Chicago, Ill.) composite landing gear braces; Toulouse-based Latécoère’s integrated RTM composite passenger door for Boeing’s 787 Dreamliner, and the tufted crash box for the McLaren Mercedes SLR supercar.

Heated and/or conductive composites were also seen multiple times on the exhibit floor. Products showcased on the show floor included those from Norafin Industries GmbH (Mildenau, Germany) and TIBTECH innovations (Bondues, France).

Equipment evolutions

Fives (Hebron, Ky.) reported that it has continued the evolution of its GEMINI Composite Processing System, a manufacturing solution capable of switching within minutes from automated fiber placement (AFP) to automated tape laying (ATL). The company says the gantry-type system cuts the capital cost of duplicate equipment, infrastructure and labor traditionally needed to install and maintain separate AFP and ATL systems. Introduced in January 2012 by Hebron-based MAG IAS, which was recently acquired by Fives, the GEMINI reportedly meets the aerospace composites fabricator’s need for mixed tape and tow formats.

“In the past, you couldn’t put these two different types of materials into the same part,” said Fives’ composites product manager, Stephen Albers. “Now, manufacturers are seeking to increase material efficiency by minimizing scrap as well as higher cost AFP.” The system enables users to employ less costly ATL material on larger plies and use AFP only on contoured areas, where it is needed.

Albers noted, “We are also seeing a broader move toward purpose-driven machines, i.e., very specialized equipment with a much higher throughput for a given type of part vs. more generic units that are slower.” He added that both trends are being driven by increased production demands.

At its stand, Lindauer DORNIER highlighted at the show its 3-D Jacquard equipment for near net-shaped preformed fabric structures and its machines for weaving monoaxially stretched or spread materials (e.g., ribbon-like carbon tows). The company also supplies machines used in spreading and coating of heavy tows for creating a tape material, as well as components for the production of stabilized or coated materials, including calendering, powder coating, extrusion and many other process options. DORNIER delivered its first weaving machines 40 years ago. Today, its rapier looms are used to make 90 percent of all woven carbon fabrics worldwide.

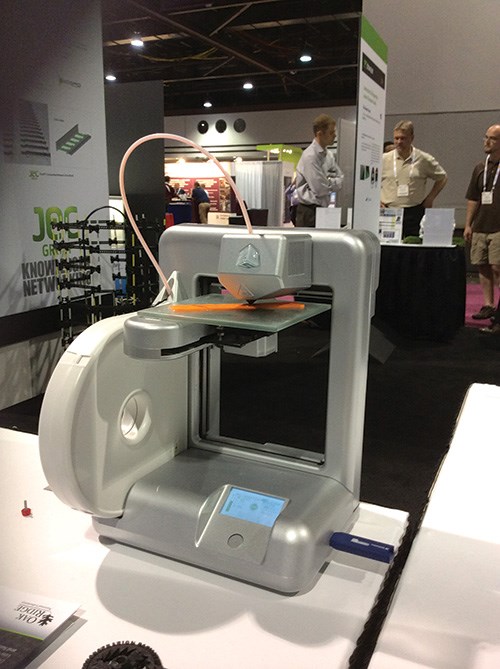

Oak Ridge National Laboratory (ORNL, Oak Ridge, Tenn.) demonstrated its 3-D printer using discontinuous carbon fiber live on the exhibit floor. The single-head printer uses fused deposition modeling (FDM) with very fine carbon filaments, 6 to 7 microns in diameter. Their discontinuity prevents issues with starting and stopping of the print head. The filaments are combined with a wide variety of matrices including acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), and nylon. The print head can also be modified to accommodate higher performance matrices like polyetherimide (PEI) and polyetheretherketone (PEEK). Through work conducted at the U.S. Deaptment of Energy’s DoE Manufacturing Demonstration Facility, ORNL has demonstrated that incorporating carbon filaments into the FDM process results in parts with five to six times the stiffness of unreinforced polymer and improves dimensional stability as well. ORNL printed several small parts (100 mm/3.94 inches) at the show but also displayed a full-size chair which it printed with a large printer, which is capable of printing objects larger than 2.4m/.7.9 ft) in any dimension.

End-use applications

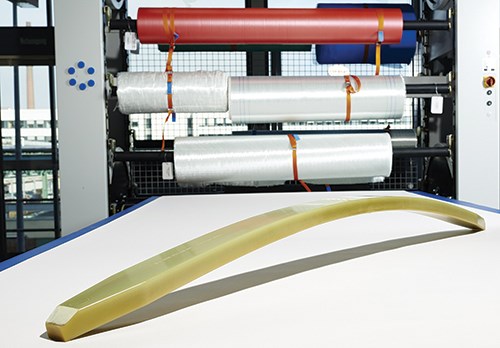

Exhibitors also called attention to the ways in which their products have achieved milestones in part production. Henkel AG & Co. KGaA (Madison Hts., Mich.), for example, displayed a glass fiber-reinforced composite leaf spring that it developed with Benteler-SGL (Ried im Innkreis, Austria) for series production, using resin transfer molding and Henkel’s LOCTITE MAX2 polyurethane resin. Originally developed for Daimler AG’s (Stuttgart, Germany) Mercedes-Benz Sprinter cargo van, the composite front transverse leaf spring is 63 percent lighter than its steel predecessor, dropping part weight from 15 kg to 5.5 kg (33 lb to 12 lb). Henkel representatives explained that the low viscosity of LOCTITE MAX2 increased the injection rate, which shortened the mold cycle time while enabling better wet out of the glass fiber in the spring’s thick preform. It also helped improve the ductility and fatigue resistance of the finished part. (Read more about the Henkel/Benteler-SGL composite leaf spring here. See also “Composite leaf springs: Saving weight in production suspension systems,” under "Editor's Picks," at top right).

Magnolia Advanced Materials Inc. (Chamblee, Ga.) announced it will triple its production space with a move in early July to a new 114,000 ft2 facility.

Composite Fabrics of America (CFA, Taylorsville, N.C.) displayed a carbon fiber composite propeller blade from Sensenich (Plant City, Fla.) featuring a CFA-made Textral custom patterned fabric. CFA worked with the propeller maker to replace a 2x2 twill that was bunching in the mold. The new fabric enabled not only an excellent surface finish, due to enhanced handling characteristics, but a unique visual appearance that differentiates this product in the market.

CPI Binani Inc. (Winona, Minn.) displayed a hull from the Bombardier Recreational Products (BRP, Valcourt, Quebec, Canada) Sea-Doo Spark, an entry-level watercraft that is new for 2014. Heralded as affordably priced ($4,999) and lightweight, it reportedly weighs half of other personal watercraft, at 405 lb/185 kg. CPI Binani worked with BRP to replace glass fiber reinforced thermoset resins in the hull with direct long fiber thermoplastic (D-LFT) molded polypropylene. The glass reinforcement was 0.5-inch long fiber at a 30 percent fiber content by weight. The new material helped BRP meet price and production volume goals and also improved the Spark’s fuel efficiency, cutting fuel burn from 5 gal/hr to 1.9 gal/hr. CPI Binani also exhibited parts for the auto industry, including an underbody shield for Cadillac and a door surround for Jeep Wranglers. Seed tank lids and inner roof panels for the agricultural industrial were also featured.

Related Content

From the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreGKN Aerospace, Joby Aviation sign aerostructures agreement

GKN Aerospace will manufacture thermoplastic composite flight control surfaces for Joby’s all-electric, four-passenger, composites-intensive ride-sharing aircraft.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More