Fokker Aerostructures BV

GKN Aerospace

PO Box 59

Hoogeveen, 7900AB NL

31 528 285343

gknaerospace.com

About Fokker Aerostructures BV

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Fokker Aerostructures BV Supplies the Following Products

- Aerospace, flight control surfaces

- Aerospace, fuselage/wing

Editorial, News, and Products

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

-

MFFD longitudinal seams welded, world's largest CFRTP fuselage successfully completed

Fraunhofer IFAM and partners have completed left and right welds connecting the upper and lower fuselage halves and sent the 8×4-meter full-scale section to ZAL for integration with a cabin crown module and testing.

-

Optimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

-

From the CW Archives: I see thermoplastics in your future

Thermoplastics are evolving quickly into larger structures and clearly will have a significant role to play in the next commercial aircraft program — whenever that’s announced. This edition of “From the CW Archives” looks back on a thermoplastics pioneer.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

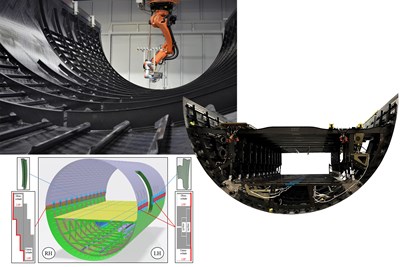

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

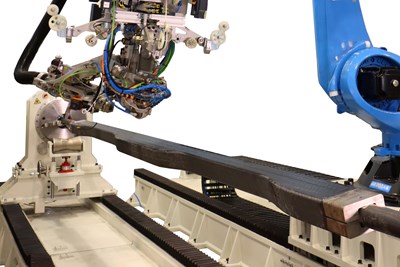

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

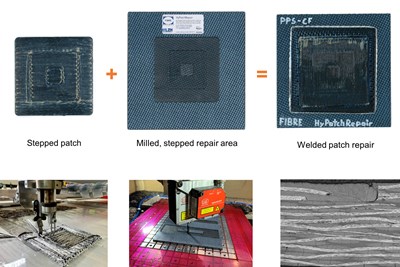

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

-

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

-

JEC World 2022, Part 1: Highlights in sustainable, digital, industrialized composites

JEC World 2022 offered numerous new developments in composites materials, processes and applications, according to CW senior editor, Ginger Gardiner, most targeting improved sustainability for wider applications.

-

SAM|XL receives grant for composites research towards sustainable aviation

Jointly with TU Delft Faculty of Aerospace Engineering, the SAM|XL field lab will receive €4.9 million for projects in liquid hydrogen composite tanks, thermoplastic composite aerostructures and smart maintenance and repair.

-

SAM|XL develops closed-loop manufacturing for composites

Collaborative R&D center at TU Delft develops sensor- and robot-based automation for Composites 4.0 manufacturing, including STUNNING project for welded assembly of a thermoplastic composite fuselage demonstrator.

-

People in Composites: November 2020

CW’s November monthly people roundup include new appointees for Lilium, ACMA, Beckers Group, AZL, Hexion and Eckhart.

-

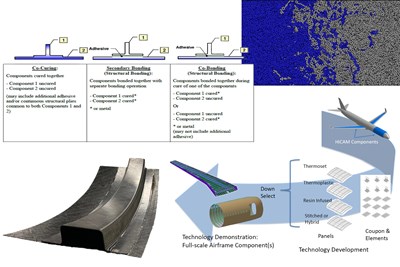

Automated aerocomposites production: Liquid molding or welded thermoplastic?

Two materials and process approaches are demonstrated for CFRP bulkhead production.

-

3D printing CFRP molds for RTM flaperon, exoskeletons and more

The Chair of Carbon Composites at TU Munich is advancing composite additive manufacturing via large-scale extrusion, continuous fiber printing, integrating heating into tools and more.

-

Proving out LMPAEK welding for Multifunctional Fuselage Demonstrator

Clean Sky 2 STUNNING project will manufacture lower thermoplastic fuselage while MECATESTERS will test LMPAEK in conduction and induction welding for parameters, cyclic loading, aging and environmental effects .

-

Plug-and-produce AFP system installed in one day and debuts at composites automation center

Addcomposites completes installations of its AFP-XS toolhead at KUKA Finland and SAM|XL in Netherlands.

-

Thermoplastic composites: Poised to step forward

The evolving role of thermoplastic materials and processes and their future in next-generation commercial aircraft.

-

JEC World 2019 briefs

JEC briefs on Bindatex, FILL, Solvay, Henkel, Web Industries, Cobra, PolyOne, GKN Fokker, Thomas Technik + Innovation and Hyosung Advanced Materials.

-

Recycled thermoplastic composites for production

Multi-year R&D at ThermoPlastic composites Applications Center (TPAC), TenCate and Clean Sky 2 demonstrate economic advantage of serial production using recycled materials.

-

TPAC and TPRC develop thermoplastic composites recycling process

Known as TPC-Cycle, the project targets production scrap by developing a recycling route for high-end and high volume markets.

-

New horizons in welding thermoplastic composites

Latest developments in qualification, production and applications for aerospace and automotive.

-

Welding thermoplastic composites

Multiple methods advance toward faster robotic welds using new technology for increased volumes and larger aerostructures.

-

CAMX 2018 Preview

CAMX combines forces with IFAI for a big Texas Event.

-

GA-ASI and GKN Aerospace expand partnership

General Atomics Aeronautical Systems Inc. and GKN Aerospace to collaborate on composite tails for GA-ASI’s Predator B Remotely Piloted Aircraft (RPA) series.

-

Composites at AeroDef 2018

Highlights from the Aerospace Defense Manufacturing Conference – AeroDef 2018 include new technologies for tooling, drilling/machining and inspection of advanced composites.

-

PEEK or PEKK in future TPC aerostructures?

Which is better for in-situ consolidated thermoplastic composite primary structures? Materials play a part as to whether a one-step or two-step process will prevail.

-

JEC World 2018: The highlights

JEC World is the composites industry’s largest trade show and did not disappoint this year.

-

JEC World 2018: Highlights

You will read more about what we discovered at JEC World 2018 in the coming weeks and months, but for now this is a quick review of some of the highlights from the world’s largest composites trade show.

-

Consolidating thermoplastic composite aerostructures in place, Part 2

Thermoplastic composite structures could eliminate the autoclave and fasteners, but will a one- or two-step process prevail?

-

McNair Aerospace Center: Closing the composites education gap

As the composites industry in South Carolina continues to expand through Boeing and its tier suppliers, composites education follows suit through the McNair Center.

-

Consolidating thermoplastic composite aerostructures in place, Part 1

After more than 30 years of development, in-situ consolidation is nearing its promise to eliminate fasteners and the autoclave, and enable an integrated, multifunctional airframe.

-

Thermoplastic composite demonstrators — EU roadmap for future airframes

There is a TPC development roadmap in Europe, supported by Airbus and a variety of aerospace consortia, and involving almost every major aerostructures supplier in Europe.

-

Fiber-metal laminates in the spotlight

Interest in FMLs is growing again as aeroengineers search for lightweight solutions adaptable to new narrowbody commercial aircraft.

-

2017 Paris Air Show is good for composites

There is definitely a lot going on this week at the Paris Air Show at Le Bourget airfield. Much of it relates to composites. Here’s a brief rundown.

-

Episode 1: Arnt Offringa, Fokker Technologies, part of GKN Aerospace

The first episode of CW Talks: The Composites Podcast features an interview with Arnt Offringa, head of aerostructures R&T at Fokker Technologies, part of GKN Aerospace, in Hoogeveen, The Netherlands.

-

Another opportunity to meet, and learn, in Paris

At the JEC World 2017, improvements in materials and processes were present at nearly every stand, with the emphasis on automotive-capable production speeds.

-

Composites industry is growing up—but hurdles still remain

It’s the era of when, not if, for the use of composite materials.

-

The resurgence of GLARE

Airbus pursues fiber metal laminates for future narrowbody construction, citing cost, weight, repair and lightning strike benefits.

-

Thermoplastic composites in flight ... for decades

Thermoplastic composite airframe components parts have a surprisingly long history. Here's one of the earliest applications.

-

Thermoplastic composite wings on the horizon?

OUTCOME, a project under the Clean Sky 2 program, aims to industrialize out-of-autoclave thermoplastic primary aerostructure.

-

JEC World: Aerospace highlights

Fokker Aerostructures BV (Hoogeveen, The Netherlands), a GKN Aerospace company, demonstrated at its stand a thermoplastic composite aircraft demonstrator spoiler, fully functional and consisting of only three parts: top skin, bottom skin and a single spar.

-

JEC World 2016, the full report

CompositesWorld's editors report on the technologies and products that caught our eye at JEC World 2016, in early March.

-

Turnkey manufacturing systems: Materials, markets and maturation

Automated production cells promise affordability and less risk in scaling up composites production, but are they really the path forward?

-

Plant Tour: Fokker Aerostructures: Hoogeveen, Netherlands

This Dutch aerospace supplier leverages its founder’s pioneering spirit from a century ago to lead the way, today, in thermoplastic aerocomposites.

-

The matrix (2015)

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here's a guide to selection.

-

Thermoplastics in Aerospace Composites Outlook, 2014-2023

Capable of volume production, thermoplastic composites will gain new market share in the aerospace industry.

-

TAPAS 2: Next steps in thermoplastic aerostructures

The Netherland's-based Thermoplastic Affordable Primary Aircraft Structure (TAPAS) consortium's TAPAS 2 team builds on the successes of TAPAS 1, taking the next steps in aircraft thermoplastic composites architecture.

-

SAMPE Europe 2013/JEC Europe 2013 highlights

Held concurrently, these two seminal European composites events weathered a rare Parisian snowstorm to plumb the depth and breadth of the industry.

-

Thermoplastic composites: Inside story

Reinforced thermoplastics buy their way into structural aircraft interior components.

-

Thermoplastic composites gain leading edge on the A380

Breakthrough manufacturing process produces lightweight, affordable glass-reinforced PPS J-nose on the worlds largest commercial aircraft wing.