Laminated composites: The original additive manufacturing process

Because fabrication of laminated composites can claim to be the original additive manufacturing process, Altair Engineering Inc.'s (Troy, MI, US.) VP of aerospace solutions Robert Yancey says it also should be the most advanced in terms of application.

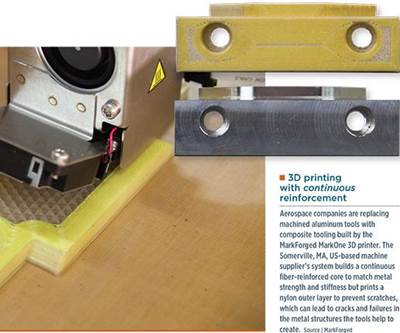

There is a lot of enthusiasm around additive manufacturing (AM) these days. From high-end applications of AM, such as the GE fuel nozzle, to the home market and hobbyists fairs, AM has captured our imaginations and unleashed our creative instincts with the potential to make anything we can dream up. Many are new to the idea of AM and think of it as a very new technology. However, with a little research, you can find that stereolithography was introduced more than 20 years ago. Further, other common AM processes, such as selective laser sintering and fused deposition modeling, are well over a decade old. (Fused deposition modeling is the basis for several technologies now in use to produce composite parts. Read more about them online by clicking on the titles “3D Printing: Niche or next step to manufacturing on demand?” and “Additive manufacturing: Can you print a car?” under "Editor's Picks" at top right.)

If you look at the composites industry, one can claim that laminated composites are the original AM technology. The idea behind AM is that you build up a structure layer by layer to form the complete part, rather than the traditional subtractive process, where you take a block of something and remove material. I remember cutting plies in a university lab in the 1980s and laying them down to create laminated structures. Before that, I remember building a fiberglass kayak as a teenager in the 1970s by laying fiberglass mats over a mold and applying epoxy resin. Both of these activities can be considered additive processes.

One of the allures of AM is that it can be mostly automated — you give the machine a design file and it builds the part. In fact, one AM technology holds some promise for 3D printing in large format. For composites, there has been a parallel effort to automate the composite lamination process. To that end, automated tape laying (ATL) and automated fiber placement (AFP) equipment has become so advanced that you can mostly automate the process of building up a customized laminated structure. These machines are used to build very large aerospace structures, and these processes are significantly speeding up the build time and ensuring more consistent quality and repeatability.

One of the cited advantages of AM is that it offers a lot of flexibility in part design. Many designers are taking their inspiration from nature, which has evolved in such a way that its structures are very specifically and efficiently enabled, in terms of shape and material composition, to carry the loads each will have to bear. The human body is a great example of efficient design.

Further, there are a lot of composites in nature — trees, plants, bones and more. These natural composites are not the quasi-isotropic laminates we commonly see employed for industrial composites. In nature, plant fibers, for example, are aligned with the primary load paths to provide stiffness precisely where it is needed. The lengths of the fibers and their orientations are continuously varied throughout the structure. We see a lot of effort these days to realize very organic-looking industrial designs, using AM to build integrated components that have internal structures that could not be manufactured, practically, any other way.

Given the modern ATL and AFP equipment now in use, can we start to think of customized composite structures that are tailored and tuned, in a similar way, to specific applications? To do so, we will need design software that can help us determine where we need those fibers, what their orientations and lengths should be, as well as when to vary the fiber/matrix percentage and matrix properties. The good news is that much of the design optimization software, such as topology optimization, genetic algorithms, neural networks, etc., were inspired and developed to mimic natural biological processes. Because nature is very efficient in the design of composite structures, these algorithms can help us design more efficient industrial composite structures. Using these algorithms, we can start to design composite structures that are truly optimized for function, and with the new, automated composite manufacturing equipment, we can build up these structures in an efficient fashion.

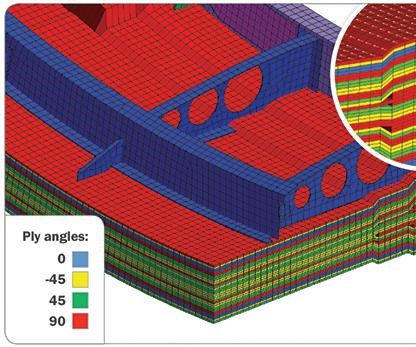

As an example of this, the figure above shows an aerospace structure where composite ply optimization has been applied. The result shows added plies on the right side, where stresses are higher, and an increase in the number of 90° plies in the thicker section. Human bones are similar in construction — with added material where you see higher stresses, aligned fibers along the directions of the major load paths, and then tapered volume as the stress field decreases.

Because fabrication of laminated composites can claim to be the original additive manufacturing process, it also should be the most advanced in terms of application. Given the sophisticated automated equipment now in use for composite laminate layup and the design optimization software that is now available, we should truly be able to enhance our composite structural designs, and move them closer to the optimized designs that we see in the natural composites all around us.

Altair Engineering Inc.

Related Content

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreNine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreRead Next

Additive manufacturing: Can you print a car?

Collaborative demonstration dispels doubt about 3D printing’s disruptive potential for direct-to-digital manufacturing of just about anything BIG.

Read More3D Printing: Niche or next step to manufacturing on demand?

With and without fiber reinforcement, additive manufacturing is making an impact, but to what end?

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More