The composites industry is constantly being shaped and reshaped by myriad forces — people, markets, technologies — all stimulating innovative new ways to apply fiber-reinforced materials in everything from boats and wind blades to airplanes and automobiles. CW Trending is a monthly video podcast that takes a closer look at these composites forces and helps you make sense of them. CW Trending features subject-matter experts, material suppliers, technology mavens and CW’s own editors to explore the ideas, technologies, trends and innovations in development or already in the marketplace.

Each month, you will have the chance to register and watch the recording live and participate in a Q&A session with editor-in-chief Jeff Sloan and senior editor Ginger Gardiner. Can’t make it the day of? Don’t worry! All of our episodes will be posted to YouTube for you to watch at a time more convenient to you.

In our very first episode, we explore the democratization of composites. Discover more about automated AFP cells for SMEs, more in-house capabilities for suppliers, online portals, robotic CT and other NDT, robotic injection molding and more.

Interested in learning more? Register for episode two: CW Trending: Composites Opportunities in a Growing Infrastructure Market

Transcript

Jeff Sloan, CompositesWorld

Hi everybody and welcome to CW Trending. My name is Jeff Sloan, I am the editor in chief of Composites World and I am joined by

Ginger Gardiner, CompositesWorld

Ginger Gardiner senior editor at Composites World. Hey, everybody.

Jeff Sloan

So, this is the first episode of CW Trending, and we hope it will be the first of many, but the question is what is it? It was the brainchild of Ginger, so I am going to let Ginger explain what CW Trending is.

Ginger Gardiner

For me, as I am writing articles, writing blogs, and talking to companies around the world, I can see trends building, I can see things coming to a tipping point, and I wanted a way to share that with our readers. Sometimes, it takes us a while for the articles to came out, for us to develop a blog or article, get it up online, and send it out to you. So in the meantime, while we are doing that, I wanted you to see what is coming up and what is going on.

Jeff Sloan

I would say on top of that, every day Ginger, Hannah Mason and I have discussions about what we are working on, and what we see happening. We thought it would be interesting for you, the audience, to have a glimpse into those conversations, and see what we see, hear what we talk about. There is the hope that CW Trending can also bring in people from outside to talk about what they are working on, and what they see happening. So, this will be a multi- pronged effort. Ginger, why don't you go ahead and get started, I know you have a presentation prepared. Why don't you bring that up, and we will get going.

Ginger Gardiner

This first episode is one that I put together on what I am seeing with regard to the democratization of composites. So, the topics involved in this for me are:

- Automated AFP cells for Small and Medium Enterprises (SMEs)and more and more capability coming in-house for suppliers, for example, the ability to make their own dry tape;

- Online portals for ordering tools and parts, similar to what we can do now with Amazon, etc.;

- Robotic computed tomography (CT), which is an X-ray technology for non destructive testing;

- And then robotic injection molding.

Alright, so the first is AFP cells for SMEs, and this is based on some reporting I've done with Effman, which is a company in Canada that does composites automation. They started a project to integrate an Addcomposites AFP head into a Fanuc robot they had on site. So, for those of you who haven't seen my blogs on Addcomposites, and all the press releases, they are a company out of Finland and they have this plug and play AFP head that they ship to you in a box, kind of like a Dell computer. You unpack it and you plug and play. They are also unusual because they're kind of upending the AFP market — instead of buying a million dollar system, you're buying a much less expensive system, or you can lease it. So, you can, I think, lease it for a few 1000 euros a month for the duration of whatever you've got going and then send it back.

The goal with this project between Effman and Addcomposites was to create not prepreg layups, but dry tape layups. So, these are high-permeability preforms that they would then use in RTM or Light RTM, and if you can see that picture on the right, what they are actually placing is kind of a woven tape with glass fiber, so it's really unusual. It is not what we are used to seeing come out of an AFP head and it just goes to show the kind of innovation that's involved. That tape is something that Effman came up with and worked with Addcomposites to do. And then also, what the real target is, it is to put equipment in the hands of small companies and fabricators so that they can build new kinds of parts using the same kind of processes that are being used by Tier 1 suppliers for Boeing and Airbus using automation and liquid processing.

Another aspect to this democratization, is increased capabilities in-house. So, if you have AFP coming in-house, in a more cost effective way, now you have dry tape, and this was an article that I wrote this year in a back-to-back series with MTorres — first,on their dry tape line they have invented. So, if you look at the picture in the bottom, you can see this big hall with production equipment in it and on the left side is a glass fiber dry tape line, and on the right side is a carbon fiber dry tape line and you can see a spool of that tape, and then some close ups. It is pretty interesting.

This effort came originally out of their work with wind blade manufacturers and trying to come up with a way that wind blade manufacturers could use AFP that was affordable. Typically, the tapes that are sold for AFP machines are not affordable for something like a wind blade. So, what they wanted to do was go with the cheapest fiber possible — a 50k carbon fiber tow or 4800 tex glass roving— and they developed a line that can go 5-10 times faster than what's being used by tape suppliers right now. So, you can get the cost down via better utilization on the capex of the equipment and the goal again is a high-permeability tape that you can make preforms with.

So, what they did for that permeability — if you can see in that lower right hand picture— there are slits that they put in the tape. Now, these aren't cutting fibers, so the fiber continuity and the mechanical performance is intact. It is just that they move the fiber out of the way a little bit so that you have better Z-direction permeability. The resin flows from layer to layer quite quickly. Then, if you see on the right hand side, that is a more narrow tape, and you can see there are these circles. That is a thermoplastic that holds the unidirectional (UD) spreadtow fibers together. So, they take 50K tow and spread it out, and that thermoplastic pattern holds it together in a tape but it also creates XY plane permeability. So, it is kind of like a flow media that is built into the tape. And that is really important, because if anybody has read articles, you know that if you are going to stack 30-50 plies of a UD tape, sometimes with carbon fiber that's a bit tricky to get the resin in there in the XY plane. So, the permeability is both in the Z-direction and in-plane.

The tape lines also, they envision, will help the industry be able to make small batches of new materials. We struggle sometimes, because the large tape suppliers, just want, you know, 1000s and 1000s of meters of the same thing, and they are not necessarily responsive to companies that want to try new things. The idea is that through this kind of approach, you could do that, and you could have companies really pushing the envelope of what is possible with new materials.

What MTorres then did was trial this tape in a Clean Sky 2 project where they built this wing box on the lower left. That is a one-piece wing box, everything except the top cover. It is the lower wing cover, the stiffeners for that cover, the frontspar, the rear spar and each of those spars have stiffeners. That is what you see there and again that was an article I wrote for March.

Jeff Sloan

Two quick questions on the Effman composites innovation. Is this just a matter of scale, that it is accessible and affordable, or is there technology here that is being implemented that we do not normally see in AFP?

Ginger Gardiner

Well, for one, the plug and play head is something we don't normally see. So that was a real disrupter when it came out, the concept of trying to scale it down, make it really accessible for people that have not normally been able to get their hands on it, because of cost reasons. The other aspect of it is really this partnership between Effman and Addcomposites to work together to make these cells. Effman, apparently their specialty is making these cells that are affordable in a range of industries, and this is what they saw as a real potential market in North America right now. It doesn't have to be the en- all, be-all. You can make a machine that can meet most of the needs for a parts fabricator and not have to cost as much. And the dry fiber permeability is an issue, especially if you're doing infusion, which of course you have to with dry fiber. .

Jeff Sloan

Next question: Are there challenges with laying dry fiber and keeping it in place and how is that addressed by MTorres?

Ginger Gardiner

So, because they are AFP specialists and they've been doing this for decades, they understand inherently the issues of laying dry fiber. They had a project that isn't included in these articles, where they built a business jet size fuselage with AFP and dry fiber. So, that gave them a really good understanding of what was necessary and this project was developing in parallel to that. So, yeah, the tape runs really well in their machines, and it's possible to do aerospace-grade laminates with the tape and their machines. They've considered all of that in this development.

Jeff Sloan

Okay, thanks.

Ginger Gardiner

So, the next topic is this portalization of the composites industry. We're all familiar with going to Amazon or eBay, and how easy that is for us to make orders. And also, what we want can be searched using algorithms and then suggestions made to us. Now, we're seeing this happen within the composites industry. One of the first examples I saw was Plyable and that's this big black box in the lower left. Plyable is a company, that helps if you want to make tooling to produce composite components That tooling could be anything from wood to plastic to epoxy foam to metal, or a composite CFRP tool — that whole spectrum. You go in, you put in your CAD file and what you think the tooling material you want is and your volume and all this, and then it comes back and works with you to optimize the tool. Then, they put that out to their base of manufacturers, to their network, and then they come back and give you a delivery time and the cost, and you click the button. It then gets shipped to you, which to me is just revolutionary compared to how we have operated.

The other thing that's interesting about it is that they started in the UK. I mean, that's where they're based and their network started in the UK. But I think it's quickly branching out from there. And that makes a lot of sense to me because we have in the world this network of all these manufacturers for tooling for parts. A lot of the small companies do the whole gamut, right? They have to be a jack of all trades. And so now you have a new way to utilize that capacity. It is kind of like Uber, where we've got standing capacity that's not always being used and here's a way to take advantage of it.

The next example is one that I wrote about in the composites 4.0 series I did last year. So, this is Dynexa, that makes carbon fiber tubes and really high-quality drive shafts, etc. And what used to happen is that their customers would send in an order, email an order into them, and they would run it through their design software and then come back and say, “Yeah, we think, you know you should optimize this way. We know you want this volume and this is the kind of timeline when we can deliver it and this is the price.” But instead of spending all of that time, they just said: “we'll have the algorithms do it.” And so now they have their customer log in and put all of that data in their portal. It then spits all that back for you and it does it in a matter of hours or a day instead of a week.

And then the other thing that was interesting is that it frees up their time to do more advanced development, and more customization that they weren't really having enough time to do before. So, it's a better use of their staff. But another part of it is that when they click the order button , all of the paper trail is now embedded in a QR code that goes out on the tubes. Their customers told them they didn't want all that paperwork being shipped anymore. And so it's much easier for them to have a tube and be able to scan it quickly and know,“Okay, it's this batch and this material.”

Finally, the last example is Airborne on the lower right.We saw at JEC 2019 that they were demonstrating this automated production line that is now operational. I think the line started with thermoset composites and is quickly moving into thermoplastic composites. And you can see kind of how that works. You upload your design andthey help you to optimize, and then they can make a laminate or part and send it to you. So, to me, it's just a whole paradigm shift in how the industry will be operating in the future, sooner than later.

Jeff Sloan

I think one advantage here is that if you're a manufacturer or an OEM who needs parts, and you don't know composites very well,this provides a portal through which you can work and rely on other experts to help guide you and make some decisions and not feel like you have to know everything there is to know about composites manufacturing. We should also add that just last week, Airborne announced they're expanding operations into the U.S. So, certainly that model is growing and then I should add there's another organization that's actually a consortium in the UK called DASISthat is a group of manufacturers including composites fabricators, CNC specialists, 3D printers, injection molders and tool makers. Again, DASIS acts as sort of a project manager and front person for OEMs who need parts and then they work with their consortium to get those designs fabricated. So, a lot of these models are popping up and I think it's gonna be really interesting to see how things unfold.

Ginger Gardiner

That's a really good point you made about the expertise and that's one of the things that basically Dynexa and Airborne both have said, is that they're taking all of their expertise and they're putting it into these algorithms and AI software to do that. It's being given to you, the customer, so that you don't have to develop that expertise yourself. So, that's a really important point. nAd the other one was that AZL Aachen, the industry and research group in Germany, is also getting machines ready for portalization and they see it coming as well.

So, the next slide is about robotic computed tomography, and NDT, again, aimed at SMEs. Computed tomography has really grown in the last five years. I started writing about it with Exact Metrology here in the U.S., which has that capability and they offer that service. And there are some other companies, such as Jesse Garant, that was offering that as well and the capability to use CT on composites was amazing to me. You can get this 3d image and all the porosity and fiber orientation for injection-molded or aerospace parts, just the minutia and the detail, the granularity you get is amazing. And it was really helpful to these big companies to track out quality and processing. However, it's expensive and so what would happen is that you end up going to the service bureaus because a CT machine is so expensive to purchase.

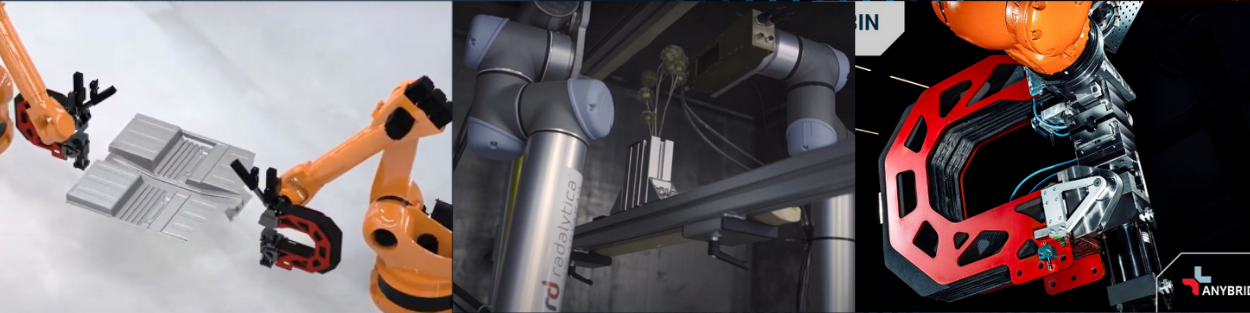

For a CT machine, basically you have a rotary table, you put the part on there, and then you have the X rays being sent through that part on the table as it goes around and you get a 360 degree scan. What has happened now is that this company in the Czech Republic called Radalytica, they're a specialist in robotic NDT, and what they've developed as you can see in the upper right hand corner is a collaborative robot system. So, one robot emits the X-rays and the other is using the next bit of the technology which is these photon counting detectors. And this technology is being used by NASA; it's just really, really sensitive. So, if you look at the lower left, what the two robots are actually imaging is a vase of flowers. And if you look at the pictures in the middle that are red and purple and then below it, you can see all the parts of the flower. We're not used to getting this type of sensitivity. Normally, you can't X-ray flowers. You can't X-ray just tissue. Normally, you're looking at bone. But this is X-ray and this is the granularity and then the resolution you get from it, which is just mind blowing, really.

As you can see, the services they can offer are imaging the surface, doing laser shape profiling, doing the CT analysis where you can see the porosity and the fiber orientation and go layer by layer to see defects. So, the goal really for Radalytica is to help SMEs access the technology that previously was really only available to large R&D groups or large aerospace companies.

In the lower right hand, you see how they're controlling the robots. It's with a mouse, which I find fascinating. And what about cost? Yeah, the cost is still in the hundreds of 1000s but it's not in the millions, and it's something you can work with them to tailor what you need. It's definitely coming down in price and that opens up a door to companies that typically wouldn't have access to this technology in-house.

And the last example today is kind of the same idea of using robotics to bring down the cost of something that we typically think of as really large: injection molding. That's more of your background, Jeff, in plastics. But when we think injection molding, we think100,000 parts, and really expensive tools, a big setup, and high-pressure presses involved. And this is a different take. Oops, this company is not in the Czech Republic — that's a copy and paste error. Sorry, they're in Germany, and a spinoff from the ILK at TU Dresden. We have written a lot about them (ILK at TU Dresden), and they do a lot of really good work. What they looked at was functionalizing parts, and how to get the overmolding functionalizing that injection molding offers to a part but in a way that a company can bring it in-house. So, they put it on the end of a robot, it's an end effector — you can see the red "U” in the top right corner. That end effector actually uses composites to make it lightweight, and the molding tool is actually in the very center, kind of upper center. If you look right below the orange robot, you'll see a twin pair of metallic plates, with a semi circle hole in the top and a semi circle hole in the bottom. That's the whole injection tool right there. It is miniaturized and it is made to functionalize a part.

If you look at that tube with the red plastic on it, that's the kind of injection molding you can get on a carbon fiber tube, for example. You can see other examples in the lower right hand where you could injection mold clips onto an underframe for an electric vehicle, perhaps, and then you can also see a robot overmolding an extrusion coming out of a line in the middle of the slide. And what's really exciting for me is to see the examples they give you. So, think about the function integration there on this slide, those are LED lights showing you can actually injection mold pockets for the LED lights, or a fastener for a cored structure. When you see the load application part, here in the middle and at the bottom, you can see there are red x's in the web of the I-beam. So, it is just fascinating where we could go with this. I'm working on blogs for Anybrid and Radalytica now and they will be posted soon.

Jeff Sloan

This is interesting to me, because if you think about how this injection molding would be done without a system like this, as you noted, machines tend to be much larger. Even something like relatively discrete parts — take that load floor in the lower right hand corner, for example — you'd have to have a tool designed to accommodate that entire load floor and then you'd injection mold around it wherever you want to injection mold around it, and none of that is trivial. It is time consuming and expensive and it is really creative to capture all that technology in a relatively compact and obviously very manipulatable system, easy to move around a part, and to apply that technology in a way that I think really serves a lot of interesting applications.

Ginger Gardiner

The injection molding tool switch-out is fairly easy, and it has a one meter reach in from the sides. So, yeah, I'm like you, I see a lot of potential here.

Jeff Sloan

Ginger,before we go what are you working on right now?

Ginger Gardiner

Oh, let's see, we're finishing up a lot of articles on additive manufacturing of composites, which is really exciting. I think that's going to be a great issue that comes out in August. And I'm getting ready to start an article about an antennaintegrated into an aircraft fuselage.

Jeff Sloan

Right. Good. Yeah, so the additive manufacturing supplement will, as Ginger just said, be asupplement to the August issue. So, you can look forward to that, and you can also look forward to the next episode of CW Trending, which will be coming in July. So, keep an eye out for that. Thanks to Ginger for doing this, I appreciate it.

Ginger Gardiner

Thanks, everybody.

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreTPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreJEC World 2023 highlights: Innovative prepregs, bio-resins, automation, business development

CW’s Jeff Sloan checks in with JEC innovations from Solvay, A&P, Nikkiso, Voith, Hexcel, KraussMaffei, FILL, Web Industries, Sicomin, Bakelite Synthetics, Westlake Epoxy and Reliance Industries.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More