Lightweight at sea — get on board

Using composites to lightweight ships is gaining momentum. Several groups are available for materials and technology suppliers to join and help develop cost-effective solutions.

Share

The European network for lightweight applications at sea (E-LASS) was established in 2013 and has more than 300 members from 25 nations, including 26 materials companies. Its aim is to advance lightweight design for the maritime industry and make the exchange of information and technology easy and natural.

Its projects have developed composites for ferries, offshore platforms, offshore wind turbine service vessels, tankers and more. And it eagerly publicizes and incorporates other groups including:

- D-LASS (The Netherlands)

- MariLight Network (Germany – its “lighthouses” are trendsetting projects/applications)

- RAMSSES consortium (funded by EU Horizon 2020 program)

- S-LASS (Sweden)

A key driver is the International Maritime Organization’s (IMO) new fuel oil regulation, mandating that starting in January 2020, ships must reduce the maximum sulfur content of their fuels from 3.5% to 0.5%. (Note, the “bunker fuel”, or residual fuel oil, used by ships is the bottom, toxin-heavy sludge in a barrel of crude oil).

The shipping industry is responding primarily by

- Searching for supply of low sulfur fuel oils which are estimated to increase costs by as much as 30%.

- Installing scrubbers to remove sulfur from ship exhaust, but equipment alone (without installation) is estimated at $1-6 million and experts say no more than 500 of the 90,000-ship global fleet could be retrofitted in time.

- Switching to liquefied natural gas (LNG), but this is also expensive and reportedly cuts into a ship’s total available capacity.

- Switching to other alternative fuels. There are projects in place testing wind power, biofuels and hydrogen fuel cells.

- Planning to cheat — industry experts estimate 10-40% of the industry will take this route, at least short-term.

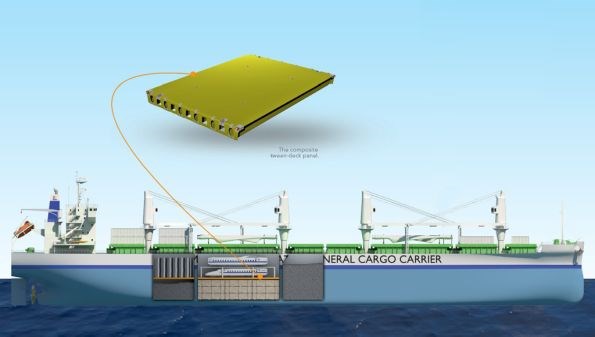

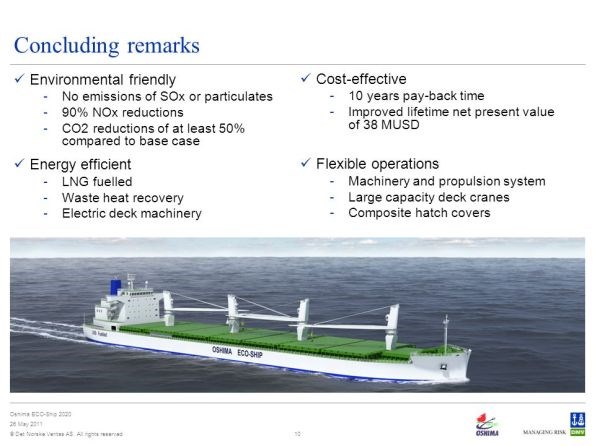

Japanese shipbuilder Oshima and classification society DNV GL have developed a general cargo carrier that uses composites to help reduce weight, energy and fuel costs.

SOURCE: DNV GL and SlidePlayer presentation by Adam Larssen, DNV.

There are also industry projects aimed at combining technologies to reduce CO2 emissions by 100%, for example, the NYK Super Eco Ship 2050 combines:

- 35% reduction in vessel resistance by remodeling the hull to decrease water friction, reducing hull weight and minimizing air resistance;

- 70% reduction in vessel energy demand by eliminating energy and operational waste;

- Using highly-efficient, electric propulsion devices powered by fuel cells with hydrogen produce onboard from renewable energy sources.

Damen Shipyards uses composite construction in a variety of marine vessels, including its new water bus taxi.

SOURCE | https://magazine.damen.com/editors-choice/composite-materials-for-the-next-generation-of-ship-owners/

Now is the time for materials and technology suppliers to stay informed and get involved. Read more below:

https://www.dnvgl.com/expert-story/maritime-impact/Composite-save-weight-and-energy.html

https://www.motorship.com/news101/ships-and-shipyards/composites-in-ship-building

https://www.compositesworld.com/articles/low-weight-on-the-high-seas

Discussion of IMO regulations for composites: https://journals.sagepub.com/doi/pdf/10.1177/1475090215620449

Related Content

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Honda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

-

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.