Making composite parts from 3D printed paper molds

Honda made autoclave-capable molds at one-tenth the cost of CNC-machined metal using Mcor's SDL technology.

Mcor Techologies is located in Dunleer, Ireland, about 60 km north of Dublin. It was founded in 2005 by brothers Dr. Conor MacCormack (CEO) and Fintan MacCormack (CTO), with the goal of developing 3D printers that would be so cheap and easy to use that the technology would become much more accessible. Though the cost of printers was coming down, the cost of materials was skyrocketing. As the brothers considered what printing material was eco-friendly, easy to work with and cheap, paper was the obvious answer. It could also be easily colored.

|

|

|

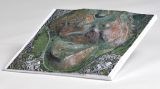

The Mcor Arke turns ordinary paper into a stable, full-color 3D part at a print resolution of 0.1mm. SOURCE: Mcor Technologies.

Quick background here. Conor earned his Ph.D. in Mechanical Engineering from Trinity College in Dublin and worked with Airbus and SPS Technologies (Jenkintown, PA, US) before founding Mcor. Fintan is an Electrical Engineering graduate from Temple University (Philadelphia, PA, US) as well as a qualified aircraft mechanic who worked with British Aerospace as a fabricator on the Harrier fighter jet.

|

|

SOURCE: Mcor and Fabbaloo.com

Honda has been using Mcor’s Selective Deposition Lamination (SDL) technology, to build molds for carbon fiber reinforced plastic (CFRP) parts. Mcor’s latest product to be released, the Mcor Arke, is lauded as the world’s first full-color, desktop 3D printer. It won the Best of Innovation Awards 3D Printing Product at the 2016 Consumer Electronics Show (CES). Mcor Technologies is also a finalist in the 2017 Edison Awards, which recognizes innovations that create a positive impact in the world.

The videos below describe how SDL and the Arke work. Honda became interested in this technology as a faster, cheaper means of creating molds for CFRP test parts vs. CNC machined metal tooling.

Mold Manufacturing Step by Step

The process Honda used to make its SDL molds is pretty straightforward. Conor MacCormack says Honda produced these 3D printed paper molds at one-tenth the cost of CNC metal molds and reported that the final parts are of equal quality.

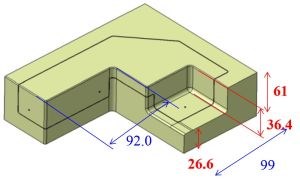

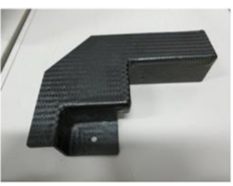

STEP 1 — Honda 3D prints the mold and applies mold release.

STEP 2 — The CFRP part is then layed up on the mold and cured in an autoclave.

STEP 3 – The final CFRP part is ready for testing.

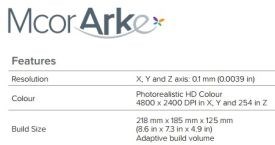

Honda also used 3D printed parts directly in wind tunnel testing and reported no difference in performance when compared to 3D printed plastic parts. However, the paper parts had a smoother surface finish and were 65% cheaper to produce. Other benefits include dimensional accuracy, which is 100 microns, and dimensional stability. Mcor claims parts do not warp or cure like UV polymer-based parts. Surfaces can also be sanded, and if needed, coated with various surface finishes.

|

|

Wing mirror prototype (left) and aerodynamic body spoiler (being flexed at right) for Honda GT Aero race car wind tunnel testing, both from 3D printed paper using Mcor SDL technology.

SOURCE: MCor Technologies.

3D Printed Molds: Paper vs. Plastic

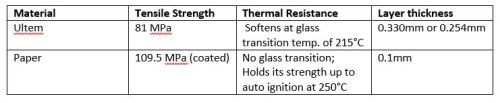

I asked MacCormack to compare the Mcor process to Ultem polymer used for CFRP molds:

"Maximum temperature the paper molds can withstand is 250°C. The maximum compressive pressure has not been established, but Honda is running their molds at 135°C and a pressure of 0.5 Mpa for a 2-hour cure cycle."

MacCormack says print costs using Mcor machines can be one-third that of basic fused deposition modeling (FDM) using plastic (like the Dimension, a professional FDM machine that can print in 9 colors of ABS plastic). However, he points out that the cost to print on the Fortus 450 which can run ULTEM materials is much more expensive, as is the machine itself. “Our machines are 12 times cheaper to buy and 10 times cheaper to run,” says MacCormack. He notes the print speeds are also faster and secondary machining of the molds is basically eliminated due to the higher print resolution.

Why Paper?

This last bit is taken from a blog written by Deirdre MacCormack, Mcor Technologies chief marketing officer.

Tensile Strength: Tensile testing of Mcor’s SDL compared to fused filament fabrication (FFF), a modified form of FDM plastic, showed an ultimate tensile strength of 32.5 MPa for SDL vs. 22 MPa for FFF.

Thermal Resistance: 3D printed ABS plastic has a glass transition temperature (Tg) of approximately 100°C, meaning it becomes soft and loses its strength above this temperature. PLA’s Tg is roughly 65°C. Paper doesn’t have a Tg, but instead holds its strength right up to auto ignition, which is 250°C.

Transformative Material: Paper is a highly porous material, containing as much as 70% air. Thus, the ability of fluids, both liquid and gaseous, to penetrate the structure of paper becomes a property that is highly significant to the use of paper. Although Mcor parts do not need to be infiltrated with another material to maintain their strength and durability, infiltration with other materials can transform the paper. Paper will take on 70% of the bulk characteristics of any infiltration material and parts can assume varying characteristics from increased strength to flexibility.

Eco-friendly: Mcor paper is bio-paper, made to conform to the “long life” International Standard ISO 9706, with an archival life of 200 years. It is also chlorine-free and carries the EU Ecolabel which identifies products and services that have reduced environmental impact throughout their life cycle, from the extraction of raw material through to production, use and disposal. Mcor paper is also certified per the Forest Stewardship Council (FSC), an international, non-governmental organization dedicated to promoting responsible management of the world’s forests. This system allows consumers to identify, purchase and use wood, paper and other forest products produced from well-managed forests and/or recycled materials.

The Mcor Arke is a huge success, compared to producing hundreds of its Iris model per year, the company is producing thousands of the Arke annually. To achieve this, manufacturing has been moved to Flex, a $24 billion company that is partnering with Mcor to produce the Arke and fulfill the company’s backlog of orders.

Related Content

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreNext-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More