Materials Sciences Corp.: Multifunctional composites

MSC draws on four decades of experience and computer modeling expertise to develop novel composite materials with the potential to make a big impact.

Share

Materials Sciences Corp. (MSC, Horsham, PA, US) was established in 1970 by a group of scientists who helped develop the constituent relations that describe the behavior of composites. Performing research for NASA, the Defense Advanced Research Projects Agency (DARPA) and the US Departments of Defense and Energy, MSC was an elite materials engineering company from the start.

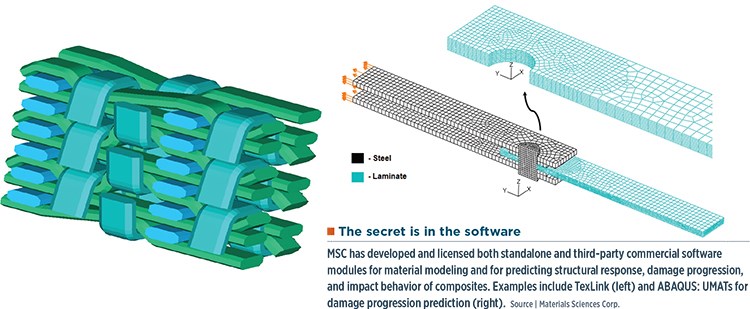

Carbon/carbon was one of the first materials MSC analyzed. “It cost $30,000 to make one cubic inch,” recalls MSC president Tom Cassin. “We had to convince the US Air Force that we had the constituent models that would accurately predict behavior without having to manufacture and test material samples.” This ability to develop CAD software to model and simulate the micromechanics of materials has become a foundational expertise for MSC. It developed, for example, the MAT162 module for LS DYNA, a multiphysics simulation software platform produced by Livermore Software Technology Corp. (LSTC) (Livermore, CA, US). “The original target was to simulate impact response,” says Cassin, “but it is now used for a variety of dynamic load analyses.”

MSC also developed two other commercially available software programs: TEXTLINK is one, written for textile analysis. “We can model angle interlock architectures and set their depth within the 3D textile,” Cassin notes, “and also simulate z-pinning. So our understanding of these fabrics informs our ability to design and produce these for composites applications.” The other, BONDMASTER, is for modelling adhesively bonded joints. MSC also has developed programs for thermal, acoustic and wave-propagation analysis as well.

“Complementary to all of these computer-aided design, engineering and prediction tools is our testing lab,” says Cassin, where MSC can verify and validate (V&V) its models. “We have to manufacture parts using a specific manufacturing process and then test to confirm the properties we have predicted. We also verify batch-to-batch variation in fibers and matrices.” Cassin explains that all of this provides the substantiation for B-basis allowables, a key part of the method currently required to certify composite structures for use in aircraft and military platforms.

But Cassin also sees this capability as strategic, because the industry is seeking ways to reduce the time and cost of design and certification. “Being able to characterize the composite material allows you to move away from conservative designs,” he says, “and also reduce the amount of testing.” Therefore, MSC has developed a unique repository of models and model-building knowledge that enables it to understand and simulate a composite from its chemistry to its fiber and resin constituents through to laminates and end-use structure behavior. Cassin maintains, “This is a powerful tool we are using to develop new material forms and solutions for the design and manufacture of advanced composite structures.”

Since the ’70s, MSC has moved far beyond composite materials research as a design services provider to perform design, analysis and prototyping projects for government and industry, and manufacture of commercial products as well. “Our mission is to develop advanced materials,” says Cassin. “Product design and manufacturing are inherently part of that, especially for composites.” He notes that now, when MSC works with a customer to develop new materials and/or structures, “we are often doing the qualification work.”

An engineer himself, Cassin has been with MSC since 1987. About 15 years ago, MSC moved from R&D into applied engineering and began exploring how to transition the company’s proprietary technologies into commercial applications. Since then, MSC has tripled in size, opening two additional US locations with dedicated staff and facilities to add significant in-house testing and manufacturing capabilities. The first, in Gulfport, MS, supports local customers and partners, including Seemann Composites, United States Marine Inc. (USMI) and large shipbuilding contractors. Its latest is in Greenville, SC.

“In South Carolina,” Cassin points out, “our operations are all manufacturing.” These include 3D weaving, fiber commingling, automated resin application, kit cutting, parts fabrication and advanced nondestructive inspection (NDI). CW recently toured the Greenville facility, with Cassin as guide, and caught a glimpse of MSC’s new materials for multifunctional composites and how they will be manufactured for commercial applications.

Although the facility, at 1200m2, is not large, it is filled with equipment and activity. Each stop along the way revealed another facet of MSC’s mission. The tour began with COUNTERVAIL, an MSC technology that, because of its proprietary nature, is formed in a portion of the facility curtained from view. It was, however, possible to view rolls of the material as it was undergoing prepregging and was subsequently readied for shipment. Cassin did, however, reveal a good deal of detail about COUNTERVAIL’s background.

A sound challenge

The technology dates back to an MSC Small Business Innovation Research (SBIR) grant to develop an improved, all-composite sonar acoustic window for naval vessels, aimed at increasing structural and sonar performance, while reducing weight and cost vs. existing versions. Cassin credits SBIRs with a great deal of MSC’s growth: “There is a high risk to insert new technology into military vessels and aircraft. MSC uses SBIRs to develop the requisite technology and reduce risk,” he says. “Once you have verified and validated it, you can now insert the technology into trial operations.”

A sonar dome, he explains, is an underwater structure typically mounted to the bow of a vessel. It houses the sonar transducers, protects them from exterior loads and damage, and is flooded with seawater to acoustically couple them to the surrounding ocean. Sonar domes demand high structural properties to resist pounding from rough seas and potential impacts. The sonar window is the part of the dome through which sound passes on its way to and from the transducers, and it must disrupt this transmission as little as possible. “The challenge is to match the impedance, or speed, of sound through the material to that of the seawater,” explains Cassin.

Notably, a sonar window is not a simple structure. Some can measure more than 10m2 in area and require compound curvature. MSC’s solution is a low-acoustical-insertion-loss composite, using proprietary fiber commingling technology. The latter blends acoustical and structural fibers into a tailored fabric and multilayer composite that enables the high-strength, protective sonar window to mimic the density and acoustical impedance of seawater, minimizing sound-wave scattering and reflection. The result is a clearer, more accurate signal.

MSC also had to reduce risk in the joint between the composite dome and the steel vessel. “Joining two dissimilar materials that have vastly different constituent properties is one of the most challenging issues when engineering composite structures,” explains Cassin. “Our strength is understanding multi-phase materials. For example: fiber-to-matrix interfaces, commingled fibers and binding systems.” MSC has developed a deep knowledge of organic polymers and metals, the latter not only as a matrix for composites but also as a bonding substrate. “The Achilles heel of composites is attachment to non-composites,” he points out. “We have specialty software that models the mechanics of joining and helps understand how to test and inspect these joints.”

MSC proved the durability of its joint design via full-scale tests, using a reconfigurable 445-kN modular test frame that simulates static and fatigue responses of full-scale ship bulkheads or girders.

Transitioning R&D into commercial products

Through this program, MSC developed a much better understanding of how to tailor a composite’s sound-transmission properties. It also recognized an opportunity to optimize materials not for sound transmission, but for sound disruption. After significant development, MSC launched COUNTERVAIL, a composite material that can be integrated into a structure to significantly reduce vibration without adding parasitic weight. Appropriately named (countervail means to act against with equal force), its characteristics, including drapability, stiffness and damping coefficient, can be tailored to the application. COUNTERVAIL comprises a lightweight viscoelastic combined with a patented fiber preform, and can be made with any fiber or combination of fibers, including carbon, glass or aramid. The preform features a fiber pattern that maximizes the vibrational energy dissipation provided by the viscoelastic component.

One of MSC’s first applications for COUNTERVAIL was in high-performance skis, with the goal to enhance the skier’s speed and control. “You only ski fast when the ski is in contact with the snow,” explains Cassin, “because the edge is actually melting the snow. If the ski chatters, it loses speed.” MSC built a model to predict and optimize the performance of COUNTERVAIL in a ski. The material has been used in boutique skis, such as Wagner and Romp, and field trials are in progress at a major ski manufacturer.

Bianchi (Milan, Italy), a bicycle manufacturer often associated with Tour de France winners, saw MSC’s demonstration of COUNTERVAIL in skis and began collaborating with MSC to apply it in a bike frame. MSC‘s computer modeling showed a potentially significant performance difference vs. Bianchi’s standard carbon fiber composite frame. Bianchi then adopted COUNTERVAIL in its 2014 Infinito CV model, which was ridden by cyclist Lars Boom to win Stage 5 of the 2014 Tour de France, a stage known for its bike frame-chattering cobblestones.

“COUNTERVAIL does not interrupt the shock of hitting a cobblestone,” Cassin explains, “but that impulse excites the bike frame structure to resonate at a natural frequency.” He gives an example of striking a bell: “The ring is still there, but with COUNTERVAIL, it will not be there for very long. Similarly, you will still feel the impulse from going over a bump, but you won’t be subjected to the vibratory envelope.” Cassin adds that in addition to the vibrational frequencies you can feel, there are hundreds that you cannot sense because the frequecies are too high. “Yet your body reacts to these, and you can calculate how much energy your body uses to counteract these vibrations.” This reduction in energy consumption pays off in performance for the cyclist, whose goal is to transmit every ounce of energy into forward propulsion. “So now we are adding value to a laminate by making it multifunctional, offering not just lightweight structure but also vibration damping and the performance benefits that come with that.”

“COUNTERVAIL is very unique, allowing you to use damping for structural vibration reduction and/or for shifting natural frequency and change resonant mode shapes,” Cassin notes. Thus, the degree of vibration and/or noise reduction depends on how the material is used and the engineering goal for the final structure. That flexibility has already resulted in varied implementation. COUNTERVAIL reportedly has not only achieved a 50-70% vibration reduction in specific carbon composite bike frames, but a fivefold reduction for a composite spar. It also has reduced peak noise transmission by roughly 30% without increasing weight in a noise isolation interior panel for a Bell 403 helicopter. Cassin also showed a prototype camera boom for a UAV that was being prepared for testing during CW’s visit. “Vibration in these gimbals and armatures makes it harder for the camera to lock onto the GPS signal,” he pointed out. “This continuous searching can render the device useless, similar to a cellphone exhausting its battery from nonstop searching for a GPS or Bluetooth signal.”

Cassin envisions a range of potential applications for COUNTERVAIL, including wind blades, aircraft interiors, boat hulls, prosthetics and automotive structures. “Radiated noise is a whole category of application for this technology,” he adds. “Traditionally, the best way to damp noise has been to add mass — like lead blankets — but these add a significant amount of weight.” Although Cassin sees the technology as far-reaching, he says MSC is pursuing a controlled rollout, targeting low-hanging fruit first.

Fiber forms for a multifunctional future

Along the right side of the facility’s open production area, a variety of weaving looms produce standard fabrics from commingled fibers followed by specially modified looms from American Iwer Corp. (Greenville, SC, US) and other suppliers for producing 3D weaves used in ballistics and blast-resistance applications. Down the center of the space are beaming and stitching machines, the former enabling the warp fibers to be readied in-house for hybrid fabric production, and the latter for attaching lightweight veils and mats to custom fabrics for infusion. Along the left side of the building, several machines are used to prepreg fabric. They apply resin to MSC’s tailored fabrics and are capable of processing thermosets, thermoplastics and high-temperature resins. Preform kits are prepared using computer-controlled ply cutters near the building’s front side.

Along the far wall are the commingled fiber machines. These feed in strands of two or more different fiber types, intermingling them to produce an integrated yarn, which then can be used in MSC’s weaving machines. Examples of commingled fibers could include glass with nylon or other thermoplastic fiber, but MSC’s versions often tend toward unusual tailored combinations, specially developed for customers who prefer to keep their systems under close wraps.

Fiber commingling is not new technology. But thanks to MSC’s long history of materials and applications development, it sees commingling as a means for entirely new multifunctional composites. One example harkens back to the sonar window work. “We take fibers that have structural properties, and then add acoustical performance, like low insertion loss,” Cassin explains. “The fibers that give the best through-transmission have low structural properties. Our ability to combine these fibers provides a tailored solution.”

Cassin adds that MSC can customize the electrical, thermal and dielectric properties of such fibers. “We have commingled thermoplastic fibers, such as polypropylene and PEEK, with carbon fibers, and also analyzed the process parameters,” he says. “From our modeling capabilities, we can synthesize thousands of materials to produce totally novel, custom composites.” Asked how realistic this is for near-term applications, Cassin responds, “The structural low-insertion-loss materials are being developed now as our next commercial products.” The technology is made possible, he adds, by two things: Development of constituent theories (e.g., partial differential equations that describe the physical behavior of each component material) and the advancement of computer power. “We can now run very complex models in a matter of minutes. These new multifunctional composite materials are achievable today.”

South Carolina and beyond

Technology growth — realized and potential — made another facility inevitable. But why South Carolina? Cassin begins with the practical. “This facility belonged to a supplier with whom we developed our 3D weaving capabilities,” Cassin replies. “The building became available and it was the right timing for us.” But he also credits the business climate in Greenville: “It offers very unique access to businesses that we want to be working with, like GE, Lockheed, Boeing, BMW and Milliken.” The South Carolina Research Authority (SCRA, Columbia, SC, US) also plays a role. MSC is a member of SCRA’s composites consortium (TCC) and has completed several projects through the Composites Manufacturing Technology Center of Excellence (CMTC, Anderson, SC), which applies composites technologies to US Navy systems.

“There is also real support here from the county and the state,” Cassin adds. “The Greenville Area Development Corp. was also very helpful, introducing us to suppliers and potential customers. Whenever we had a need, they did their best to connect us to resources.”

Cassin says this type of networking and connection to resources is vital for small businesses. “We tend to work with engineers, but they often are not the decision makers. You need a way to bridge that gap, and the folks in South Carolina understand this well, offering real help toward commercializing new products and processes.”

That, indeed, is MSC’s main priority with the Greenville facility. “Developing new material forms is a great business for MSC,” says Cassin, “but for us it is only the first step. The real payoff is seeing these materials used in defense, industrial or commercial applications. The ability to make a product perform in a completely different and better way is our focus.”

Related Content

Robotic NDT inspection solutions, services enhance multitasking capabilities

CAMX 2024: Matec Instrument Companies Inc. presents its range of nondestructive ultrasonic testing technologies, including robotic inspection systems for increased efficiency and reduced physical strain.

Read MoreInfrared NDT well-suited to demanding in-service, manufacturing and research applications

CAMX 2023: High-precision, cost-effective thermographic NDT technologies offered by Thermal Wave Imaging addresses real-world inspection challenges.

Read MorePortable digital ultrasonic imaging achieves in-service, field and manufacturing inspection

CAMX 2023: 2D array ultrasonic NDT for composites, metals and other materials is made possible through Dolpitech’s dolphicam and dolphicam2+ matrix transducer technology.

Read MoreLaser NDT, DIC systems demonstrate optimized noncontact composites inspection

CAMX 2024: Dantec Dynamics is presenting three of its laser shearography NDT and DIC devices, geared toward reliable measurement results.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More