Multifunctional composites: past, present and future

Dr. Les Lee at the Air Force Office of Scientific Research and Dr. James Thomas at the U.S. Naval Research Laboratory give insights into the history of multifunctional composites, the drivers for their development and where they are headed.

As the Nov 2015 feature "Aerocomposites: The move to multifunctionality” was being readied for press, Dr. Les Lee, program manager for Multifunctional Materials and Microsystems at the Air Force Office of Scientific Research (Arlington, VA, US), and Dr. James Thomas, section head in the Multifunctional Materials Branch at the Naval Research Laboratory (NRL, Washington, DC, US), were just returning from the 20th International Conference on Composite Materials (ICCM 20, Jul 19-24, 2015, Copenhagen, Denmark). There, Multifunctional Composites was one of seven conference “themes” with presentations and discussions throughout the week. Though it was not possible to include CW’s interviews with Dr. Lee and Dr. Thomas in the feature article, fortunately our readers can access their insight and interesting updates on multifunctional composites here.

History and beginnings via DARPA

Dr. Thomas explains that multifunctional materials began to take form in the late 1990s. “NRL was doing research, sponsored by Defense Advanced Research Projects Agency (DARPA, Arlington, VA, US), on porous materials for improving structural performance at reduced weight. For example, using porous metal lattice materials in aircraft wing fuel tanks to provide structural stiffening and improved fuel retention (slower leaking) in case of perforation by enemy projectile threats. This work sparked the broader idea of endowing ‘parasitic’ structural material mass/volume with other useful functionalities, thus creating multifunctional materials, for more effective reductions in system weight/volume.”

Following this, DARPA inaugurated a new program, Synthetic Multifunctional Materials, in the early 2000s, focused on a variety of novel multifunctional materials. (Dr. Lee cites L. Christodoulou and J. D. Venables, "Multifunctional material systems: The first generation," JOM-Journal of the Minerals Metals & Materials Society, Vol. 55, Dec 2003, pp. 39-45.) NRL participated in DARPA's new program, researching structure-plus-power materials for unmanned air vehicle (UAV) systems. Three concepts were developed including: structural-batteries in UAVs; autophagous (self-consuming) materials — i.e. the structure would consume itself to provide power; and ‘variform structure-power’, combining autophagous and morphing concepts, linking structural shape change with propulsion fuel consumption.”

Dr. Thomas says that of the three structure-power concepts, structure-battery went the furthest in development. “We were able to integrate Li-ion cells into UAV wings as structural skin to reduce weight, which led to an increase in flight endurance time. Our research team, which included AeroVironment (Simi Valley, CA, US) and Telcordia Technologies (Red Bank, NJ, US), built several small electric-powered UAV prototypes or micro air vehicles (MAVs) — the WASP MAV, with wing structure-battery as proof-of-concept demonstrators.” Thomas also mentioned, “We were one of ten or so different teams on this DARPA program that ranged in size from large to small with industry, university and national laboratory participation.”

Dr. Lee observes that Multifunctional Materials as an area of research has progressed significantly from its DARPA origins. “At ICCM-17 in 2009, there was only one session on multifunctional composites, but this theme filled an entire week at ICCM-20 this year.” He notes that “a wide mix of approaches are pursued now for the design of a material, structure or system that has the ability to perform multiple functions through judicious combinations of structural properties and at least one functional capability.” He lists examples of the latter: energy harvest and storage, chemical reactions for self-healing, control of thermal conduction, sensing of internal and external threats and altering of structural shape on demand. These are dictated by the system requirements. “Some researchers try to design multifunctional materials that emulate biological systems, in which jointed frameworks and complex materials impart multiple functionalities integrated over a wide range of length scales,” says Lee. “Others take a more pragmatic approach in trying to design multifunctional material systems that start with conventional load-bearing structures and incorporate additional layers, microsystems or devices to add functionality. Both approaches aim to deliver truly dramatic improvements in system-level efficiency instead of incremental improvements delivered by traditional design.”

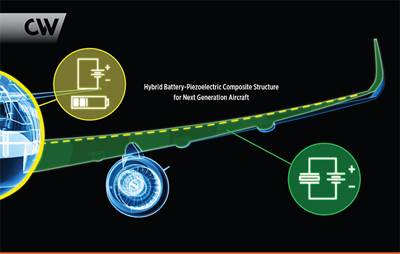

He gives an example by describing initial efforts that used an engineering approach to pursue piezoelectric actuation systems via smart materials “to transfer mechanical to electrical energy and vice versa. These materials deform with applied current, and are now commonly used in structural health monitoring (SHM) systems.” Lee explains that this actuation concept is the early basis for the morphable wingtips being demonstrated now (see FACC news item). “The wingtips worked well but the mechanical power is not very large. The programs then were trying to change the wing surface area, but you just couldn’t use piezoelectrics to effect such a large magnitude of change.” He says that smart materials have advanced a lot since that initial attempt in the 1990s, “Not only are there many new materials, the trend now is to combine materials, for example piezoelectric composites, shape memory materials and structural batteries, instead of using only one type of smart material.”

Why multifunctional structures?

What is the military interest in multifunctional structures? Thomas answers, “We need systems with a wide range of capabilities that are energy efficient. For example, a fixed-wing aircraft may need to operate under multiple flight regimes like steady-state cruise and close-in maneuver. A wing configuration optimized for one flight regime will be sub-optimal (performance and efficiency) when operating in another regime(s). If the lift surfaces can morph to an optimal configuration for the required operations and ambient conditions, gains in aircraft system performance and efficiencies can be realized.”

Dr. Lee points out that piezoelectric sensors have made a big contribution to SHM. “So can we link and utilize this SHM sensing network with an actuation network? Can we constantly monitor wind conditions, temperature and strain, and then use that data to adjust wing shape?” He adds that the defense industry is just like the commercial aircraft industry in wanting highly reliable systems, even more so. “We want structures that can sense, diagnose and then change to remediate any issues. Because we don’t know which damage will become critical, the majority of aircraft structure is overdesigned and heavy.” So this is the appeal of self-healing systems which activate when and where cracks form. Working like a microvascular system in the human body, the aircraft which can self-heal as these cracks develop can survive and perform longer. Dr. Lee notes that the Univ. of Illinois (Urbana-Champaign) has been working on this since 2001.

Another motivation for multifunctional materials is improvement in autonomous vehicle performance and capabilities. NRL developed structure-battery composites for use as hull structure on electric unmanned underwater vehicles (UUVs). “The power source for an electric UUV is typically a large battery pack centrally located within the hull,” Thomas explains. He notes that “moving the battery cells into the hull structure can free-up space for additional energy storage (e.g., fuel/oxidizer for fuel cell power) or payload. Multifunctionality, in this case, can provide an increase in mission endurance and payload capacity while maintaining vehicle buoyancy.” It also distributes the power source, which helps alleviate safety risks associated with large Li-ion batteries. “If you separate the individual cells in the battery, you greatly reduce the risk of a catastrophic battery fires. The large amount of thermal energy generated when one cell goes bad (shorts out, heats up, etc.) only affects that cell. The physical separation prevents run-away ignition of the other cells. They may heat-up under high power discharge conditions, but there should be enough time for battery safety circuitry to isolate the short and stop the current flow.” Thomas sees important implications for the automotive industry if this works, referring to progress already made via the EU-funded STORAGE program to develop structure-power components (capacitors and batteries) for automotive applications.

In general, the unmanned autonomous vehicle community is interested in multifunctional materials because of severe weight and volume (size) limitations. “This includes air, ground and marine vehicles,” says Thomas, pointing out that “multifunctionality is truly essential for very small unmanned systems (e.g., nano-UAVs). Parasitic packaging and structural weight and volume can easily overwhelm the design margins as the system size shrinks.”

Future developments

Thomas notes that multifunctional materials are receiving a lot more attention now, with a wide variety of technologies in development, “but I’m not aware of any particular multifunctional material ‘type’ (structure-plus-X) that has taken the lead really.” Dr. Lee adds that there is also a wide variety of applications, with the Air Force pushing progress in more futuristic concepts. He lists three areas specifically:

- Autonomic Systems — a sensing material that can adjust its properties by itself in response to its environment.

- Adaptive Systems — an example of which is a morphing aircraft wing which is currently achieved using heavy, hydraulic actuation. DARPA tried with smart materials but they didn’t provide sufficient power 15 years ago. Now the effort is refocused on a new generation of sensing materials.

- Self-sustaining Systems — an aircraft with its own energy harvesting system and structural batteries to store and release this energy.

“These new initiatives are based on active materials,” Lee says, “We hope to achieve truly bioinspired aircraft, mimicking how bird wings deform during flight and diving for aerial maneuvers.” One of the avenues pursued for this in the past was shape memory alloys. “But these too have limits,” notes Lee. “So now we are combining these with some of the new materials via a hybrid approach. One single approach cannot handle the whole of a system’s requirements. You must combine technologies.” Lee says this “hybrid approach” technology is still decades away from application, however.

System Performance and Design

Dr. Thomas brings up a key consideration in this new world of multifunctional materials, “Design and optimization of a multifunctional material should be based on enhancements in system performance, not sub-system performance. For example, in classical design, the separate structural and battery sub-systems of an electric UAV are independently optimized for stiffness and strength (structure), and energy storage capacity (battery). Design of a multifunctional structure-battery for electric UAV applications requires a multidisciplinary approach evaluating sub-system configuration effects on overall system performance (e.g., UAV mission time).” He stresses that a multifunctional structure-power composite will likely not show the best possible structural or energy-storage performance, but the combination can still provide useful gains in system performance not otherwise attainable while still satisfying structure and energy-storage requirements. “You’re never going to create a structure-battery material with the structural performance of unidirectional CFRP or the energy storage performance of a stand-alone Li-ion cell,” he asserts, “but the multifunctional material may improve system performance beyond that possible with unifunctional sub-system designs, if you can continue to meet all of the related system requirements.”

However, there are issues. “If you have a single battery fail, you don’t want to have to replace an entire structure,” says Thomas. So this points toward a modular design approach. “Take a small electric UAV, for example, which operators want to have flying at all times. You can’t build the battery into the structure because re-charging takes the vehicle out of commission for one to two hours. However, you might consider a modular design with detachable wing-batteries that can be quickly removed and replaced on a fuselage housing the propulsion and payload sub-systems. This allows for maximal airborne operation of the UAV and the possibility of having different wing configurations that enable a wider range of mission flight regimes.” Thomas points out, “You have to think differently in multifunctional design. It requires attention to system-level implications right from the start, which is not the traditional approach to ‘materials’ design.” He reiterates that focusing on a generic multifunctional material’s properties may be interesting and useful for advancement of the technology, but “systems-level work must be done before a multifunctional material can buy its way onto an application. This is why multi-disciplinary teams, including industry and academic groups, are so important. You can exploit their diverse understanding of different system requirements.”

How far out is “the future”?

“Some concepts are 10 years or less,” says Thomas. “For example, in the UK and Sweden they have made actual car parts that have gone into prototype testing.” He notes that aircraft OEMs are looking at small-scale energy harvesting to power distributed sensors. “But this is a very tight scope and local application.”

Both Lee and Thomas point to the fact that multifunctional materials will be featured in a Gordon Research Conference starting in 2016 (Jan 31-Feb 5, Ventura, CA, US). “These are very different from all other conferences,” says Lee, “more of a closed conversation among scientists.” He says that when an area of research gets to this point, then it has become a real scientific field with hundreds of active scientists. The week-long conference will cover 14-15 different topics without any press or media recordings or proceedings in order to encourage open presentations and discussions.

“We are not really satisfied with the technology achievements so far in MAVs/small UAVs,” says Dr. Lee. “These have to be extended to real aircraft.” He asserts that morphing must be adapted, “You cannot use flapping wings with conventional aircraft. So, how do we change wingtip shape with morphing materials?” He agrees that the materials have much better capability now, and much progress is being made in combining materials. “We are still 20 years away from flying these technologies on large aircraft, but the steps being made are encouraging.”

Thomas notes, “For small-scale unmanned systems, a unique system metric can often be defined; for example, mission flight time is often a primary objective for small electric UAVs.” He continues, “You can express the flight endurance time as an equation in terms of parameters like component weights, energy storage capacity and propulsion and aerodynamic factors. Such an equation can guide the design as to where multifunctionality might make sense. This is obviously simpler than the case with manned aircraft, where there are multiple, complex metrics and constraints for the system.” Lee adds, “We are grateful to be working in this field and in a position to lead this trend. At the same time, we are constantly amazed by the new concepts being introduced by younger generation of scientists.”

Related Content

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreNext-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

Aerocomposites: The move to multifunctionality

Designers envision aircraft components that do more than bear structural loads, but must first confront great complexities to actualize greater functional efficiency.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More