Multilayer thermoplastic tapes, AFP and resin infusion for more democratic composites

Novotech advances new materials and more affordable automated processes for small aircraft and beyond

Novotech (Naples, Italy) started as a spin-off from the University of Naples “Federico II” in southern Italy, founded by professor Leonardo Lecce in 1992. “We have supported general aviation firms and provided R&D services across Italy,” says Lecce who is now Novotech’s CEO. “We have provided structural analyses for aircraft parts and also helped with aircraft development.”

Located close to the Leonardo factory which makes the composite fuselage sections for the Boeing 787, Novotech began to focus on composites in 2014. It purchased an automated fiber placement (AFP) cell from Coriolis Composites (Queven, France) and developed out of autoclave (OOA) processing, including resin infusion and thermoplastic composites manufacturing, with special expertise in in-situ consolidation using AFP.

Novotech has participated in numerous industry research projects, including:

- MESEMA (Magnetoelastic Energy Systems for Even More Electric Aircraft)

- SARISTU (Smart Intelligent Aircraft Structures)

- ASAM (Advanced Simulation of Aircraft Mechanisms)

- LAMITECH (Innovative Testing Methods for Automatic Layering of Hybrid Composite Materials)

- PROALATECH (Structural Characterization and Repair Solutions Analysis of Innovative CFRP Empennages)

- FACE (Friendly Aircraft Cabin Environment)

- AIRGREEN 2 - CLEAN SKY 2 (Development of innovative wing concepts and methodologies for next generation regional aircraft)

- SISTER CHECK (Investigation and integration of innovative system for AFP Non-Destructive Inspection)

- TRINITI - CLEAN SKY 2 (Multi-Material Thermoplastic high pressure Nitrogen Tanks for Aircraft)

- NHYTE - H2020 (New Hybrid Thermoplastic Composite Aerostructures manufactured by OOA)

“We also have a special relationship with Cytec in the UK, developing new composite materials and processes” says Lecce. Note that Cytec was acquired by Solvay and the location being referenced is Solvay Composite Materials in Heanor, U.K. — a site with a long history of innovation, including the double diaphragm forming process recently tested via the RAPM program. “Our last such activity was developing an OOA thermoplastic process that uses a new, innovative press that combines PEEK (polyetheretherketone) and PEI (polyetherimide) into a new composite material.” This new material, equipment and process has now been demonstrated in a carbon fiber-reinforced plastic (CFRP) aircraft stringer, made using AFP in-situ consolidation and welding via the NHYTE project.

NHYTE

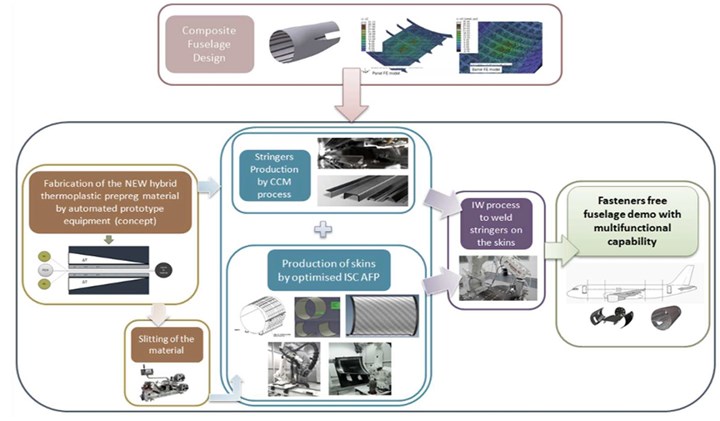

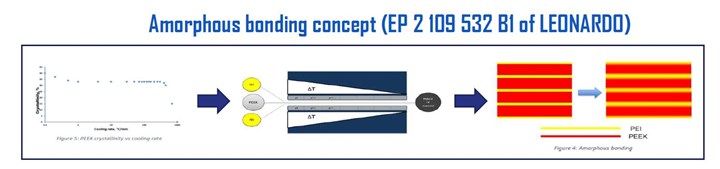

Funded by the European Commission Horizon 2020 program, NHYTE is a research project conducted from May 2017 to October 2020. “NHYTE is about using amorphous bonding to enable sustainable temperature and process conditions for thermoplastic composites,” explains Dr. Marco Barile, NHYTE project coordinator and CTO of Novotech. This amorphous bonding (see diagram below) is a concept patented by another NHYTE partner, the aerostructures division of Leonardo (Rome, Italy) which has multiple production facilities in southern Italy.

“With the material developed in NHYTE, we can overcome the current material limitations with AFP in-situ consolidation (ISC) of thermoplastic composites (TPC). Instead of processing at temperatures just under 400 degrees C for the semi-crystalline PEEK polymers, we can heat just above the 215-degree glass transition temperature (Tg) for the amorphous PEI layer. The melt and cooling of PEI is also quicker, not having to be so controlled versus PEEK.” Barile notes that this concept can use other amorphous thermoplastics. PEI was chosen because it bonds well to PEEK, a material well-proven in multiple AFP aerostructure demonstrators.

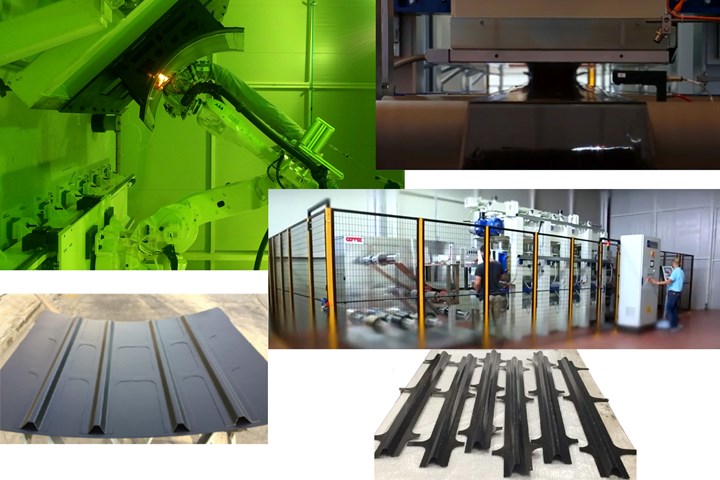

Concept for the NHYTE project’s new multilayer thermoplastic composite material (left) and the press used to make it (center). The material is slit into tape for automated layup using a Coriolis AFP machine. Photo Credit: Novotech.

This new material developed in NHYTE was produced in a continuous press designed by NOVOTECH. Orma Macchine (Bergamo, Italy) supplied the press body and COMEC Innovative (Chieti, Italy) provided the winding and unwinding modules. “This press can make a continuous roll of material that we then slit into slit tape for use in an AFP machine,” says Barile. Three different materials enter the press from the left, as seen in the image above. “We have PEI on top and bottom and then PEEK in the middle,” Barile explains.

As a semi-crystalline polymer, PEEK provides the high mechanical properties necessary for primary structures, while the amorphous PEI layers provide fast, simple melting for bonding. “We control the the pressure and cooling of the material along the press plates, starting from about 400 degrees C at the beginning of the press to less than 200 degrees C at the end of the press. The result is one material that is a combination of the three input layers.”

This new kind of thermoplastic tape is already consolidated during manufacture, so that during AFP, it needs only to be heated to melt and compact the PEI layers for amorphous bonding. The result is a laminate comprising fully consolidated PEEK to PEI tape and PEI to PEI layers, as shown in the Leonardo patent. This AFP process presents less hurdles versus current AFP ISC using PEEK and PEKK (polyetheretherketone) tapes. As explained in Part 2 of my 2018 feature on in-situ consolidation, current AFP ISC requires heating the tape and substrate to melt temperature, placing the tape onto the substrate and then consolidating with a roller so that the cooling process is precisely controlled, enabling the semi-crystalline polymers to achieve sufficiently high crystallinity (30-40%) and low voids (<3-5%) for structural properties.

Critics of AFP ISC claim it is too slow — a laydown rate of 60-100 mm/s versus 600-700 mm/s for the “two-step” method comprising fast AFP layup followed by a secondary step in oven or autoclave to fully consolidate/anneal thermal stress in the laminate. “With our material, you can achieve AFP laydown rates that are not as slow as typical in-situ consolidation and the heating required during AFP can also be kept below 300 degrees C,” says Barile. “You can close the performance gap with standard materials that we have now.” Here, Barile is comparing AFP ISC of thermoplastic composites to thermoset composites used in the Boeing 787 and Airbus A350 aircraft. “With large components like fuselage sections, the problem is with affordability when using autoclave cure. Thermoplastics enable a more affordable production process, but you have high temperatures and slow AFP rates with the aerospace-grade materials currently available on the market. Our approach helps to solve these issues. We can reach about 30 percent crystallinity in the tape via the continuous press. Thus, you have that crystallinity in the part and are only working with the amorphous layer during AFP. Though this is still an experimental material, which can be improved, the aim of the NHYTE project is to have a one-step manufacturing process that you can use in structural aerospace applications.”

Tape and AFP optimization

“The first multilayer tape materials were made here in Novotech,” says Barile. These tapes used Sabic (Riyadh, Saudi Arabia) Ultem 1000 unfilled slit film for the PEI and APC-2/AS4 carbon fiber-reinforced PEEK tape from Solvay. Total thickness was ≈0.26 millimeters, comprising PEI layers that were either 1 or 2 mils (.001 or .002 inch) thick. In the first phase of the project, multiple coupons of both variations were tested for interlaminar shear strength (ILSS) in order to validate the hybrid thermoplastic material manufacturing process. Small coupons were also tested by NHYTE partner Applus Laboratories (Barcelona, Spain) for a full range of mechanical properties including tensile and compression strength and modulus, open hole compression (OHC), filled hole tension, compression after impact (CAI), barely visible impact damage (BVID) and properties after fluid conditioning.

“We didn’t have the same experience as thermoplastic composite tape suppliers, so the quality of the material can be improved. For example, the fiber volume varies from low to high through the thickness, which affects the properties of the tape and laminate, including ILSS. But NHYTE was aimed to demonstrate the concept, which we have done.”

NHYTE project optimization of the in-situ consolidation AFP process for the new, multilayer PEI/PEEK tape, including a design of experiments (DOE) approach (top left) and numerical simulation (bottom left) for predicting the optimal laser heat load during tape laydown. Photo Credit: Novotech.

As can be seen in the images above, optimizing the AFP process for the new material required significant experimental work. “We also used a design of experiments (DOE) approach to optimize the AFP parameters and a tool was developed by NHYTE partner University of South Brittany (USB, Lorient, France) to improve the laser heating load via predictive numerical simulation.” notes Barile.

AFP in-situ consolidation process schematic. Photo Credit: Novotech.

This simulation was first used on the APC-2 tape to verify the quality of thepredictive tool and then it was applied to the new, multilayer material. A paper on this work has been submitted for publication in the journal Composite Structures. “You are modeling the heat conductivities at the nip point,” says Barile. “We then verify experimentally what was predicted in the numerical simulation. This is needed to determine the best compromise between laydown speed, melt flow of the polymers and aging [cooking] of the composite lamina. It’s a balance of several variables during the in-situ consolidation process. We look at the decrease in temperature of the incoming tape onto the tape already placed on the tool. If you can manage this change in temperature, you can reduce the residual stress in the laminate. So, we worked to assess the variation in temperature during laydown. You must customize the heating according to the shape of the path and the orientation of the lamina.

Stringer and fuselage demonstrators

Schematic for continuous forming process for composite stringers in NHYTE project. Photo Credite: Novotech.

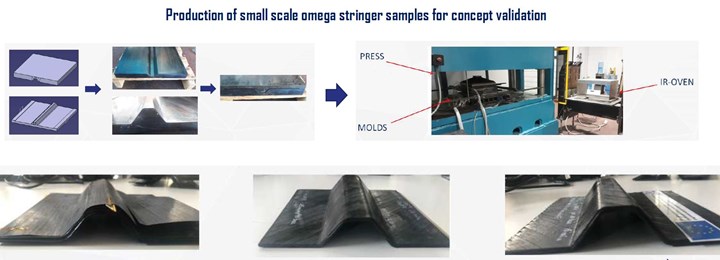

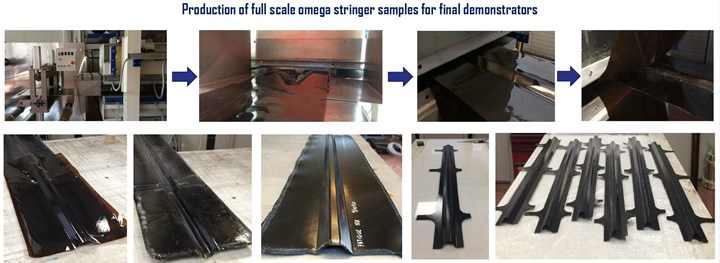

The next step was to produce stringer demonstrators, first as small-scalesamples made with a stationary press and then as demonstrators of a continuous stringer forming process to verify what would be required for industrial parts production. These stringers were then attached to an AFP fuselage skin panel demonstrator using induction welding developed by the R&D organization CETMA (Brindisi, Italy).

Did the new, multilayer material offer any advantages for induction welding? “It basically processed the same,” says Barile. “However, it was not easy for CETMA to define welding process parameters because our new material has a lower amount of carbon fiber versus standard tapes.” The stringer demonstrators and final fuselage panel demonstrator were then tested by Applus. NHYTE project partners University of Bath (Bath, U.K.) and Leonardo Aircraft also used NDI to assess the quality of panels and stringers.

“We’ve made a lot of coupons and small parts, as well as the large demonstrator,” notes Barile. “Test results from Applus are very good considering the lower cost of the manufacturing process versus what is standard now. We are 20-25% lower in strength and stiffness properties versus standard thermoplastic tape materials currently available, but we have identified improvements with the process that should help to improve this.”

NHYTE ended on October 30, 2020. “Our idea is to proceed with a new project to include all of the improvements we have in mind,” says Barile. “We have proven how to make the material and how to process using AFP in-situ consolidation, continuous forming and induction welding. Now we need to further optimize for industrialization.” Novotech is seeking to proceed with same consortium enriched with new partners.

Notably, Leonardo is also working to improve AFP in-situ consolidation using induction welding and TPC tape that can be heated and cooled quickly. In addition, encouraging results on PEI/PEEK multilayer composites have just been published by researchers at IMDEA Materials Institute (Madrid, Spain) and FIDAMC (Madrid, Spain), the latter being a leader in AFP in-situ consolidation for many years now. For more technical papers, see NHYTE’s publications.

SWING project

The Smart Wing for New General aviation (SWING) is a project that started with an endorsement from Piaggio Aerospace (Villanova d’Albenga, Italy) and is co-funded by the Italian Ministry of Economic Development (MISE). In addition to Novotech, the Italian project consortium comprises technology development firm Protom (Naples) as coordinator, Laer Aeronautical Manufacturing (Airola), A. Abete Aerostructures (Nola) and aerospace design specialist ItalSystem (Avellino). One of the SWING goals is to adapt automated out of autoclave (OOA) composites processes — including AFP and liquid resin infusion (LRI) — for cost-effective and sustainable production of smaller aircraft, using Piaggio’s P.180 Avanti forward wing as a demonstration platform.

In the SWING project, Novotech aims to help design, produce, test and validate an integrated wing box demonstrator, representative of the Piaggio P.180 forward wing using AFP and LRI. The violet section shows the upper panel infused with integrated stringers, which will be joined to the lower panel (with integrated stringers) and front/rear spars. Photo Credit: Novotech.

“The idea is to produce the forward wing of the P.180 in just two main parts: an upper panel and a lower panel, both molded with integrated stringer and spars,” says Lecce.

“For us, this started with our work as a qualified laboratory for Solvay in the U.K. We have cooperated since 2015 on new materials and processes for AFP, LRI and thermoplastic composites. We were making dry preforms using Solvay’s PRISM TX1100 dry fiber tape for use with AFP. These preforms were then infused with Solvay PRISM EP 2400 toughened epoxy resin and cured in an oven. We were doing this work in the frame of AIRGREEN 2 project for the Clean Sky 2 Green Regional Aircraft program, and then continued forward in the SWING project.” Note that PRISM TX1100 and PRISM EP 2400 were qualified by United Aircraft Corporation for production of the first resin-infused wing for a commercial aircraft — the Irkut MS-21 single-aisle jetliner manufactured by AeroComposit.

Small-scale demonstrator for SWING project. Photo Credit: Novotech.

The molded upper and lower panels will be joined using structural adhesivethen statically tested next year. “In parallel, we are characterizing another composite based on TX1100 dry tape and a resin blend from Covestro (Leverkusen, Germany) that can be a valida alternative to aerospace grade resins, in particular for sectors that require higher production rates” adds Barile. “This resin is not as high-performance as those systems, but it works well with infusion and meets requirements for the wing box. There must be some compromise if you want to reduce cost. We hope this development will contribute to introducing AFP technology into general aviation. It could also be used in the automotive sector.”

TRINITI

Novotech is also working in the Clean Sky 2 project TRINITI — Multi-material thermoplastic high-pressure nitrogen tanks for aircraft — which started in 2019 and will end in 2021. Novotech’s entry into this project once again evolved from development with an Italian aerospace company. “We were working to verify the potential of AFP using our multilayer tape in the production of cryogenic fuel tanks for launch vehicles versus the current filament winding processes used,” explains Barile. “Essentially, TRINITI will develop a multilayer material concept similar to NHYTE and then make a tank using AFP in-situ consolidation.”

“The advantage of AFP with respect to FW,” he continues, “is that you can decide where you want to place the material. You are not constrained by filament continuously wound around the part. Consider a tank where you have a lot of material at the end caps because you can’t cut the material during filament winding. By cutting and restarting fiber/tapes where you want with AFP, material is used only where it is needed. Thus, you can manage gaps between the tapes, which is important to prevent gas permeation. To do this with filament winding, you have to increase the material applied, even because with AFP you use slit tape ,not towpreg. And then with in-situ consolidation, there is no need for an autoclave. We have demonstrated that AFP could be a feasible alternative and very affordable.”

“Currently, CETMA is carrying out gas permeation tests to assess the performance of the multilayer materials versus the specifications,” says Barile. Requirements have been provided by the topic manager, Diehl Aviation (Gilching and Dresden, Germany) for a high pressure long-storage nitrogen tank used in aircraft fire-suppression systems. These tanks must withstand temperatures of -55°C to 85°C on the ground, -40°C to 70°C during in-flight operation and pressures up to 1,000 bar.

“The goal is to reduce weight and fabrication steps,” he notes. “However, the cost of manufacturing using this method has to be defined. Weight is saved by not placing unnecessary material, but filament winding is a faster process compared to AFP.” Another factor is that this type of tank typically has a metal or plastic liner that is overwrapped with CFRP. Barile says TRINITI is trying for a liner-less (Type V) tank. “We will avoid gas permeation by using a low-void AFP laminate. We are testing at CETMA now with different combinations of materials and preparing to downselect. We will then build a prototype tank, but the design of the tank depends on the downselected material and final process. So, this is what we are working toward now. The testing activity will be carried out by CTL Composites (Galway, Ireland).”

SEAGULL

The challenging project SEAGULL was started three years ago. “Our goal is to develop a new generation small hydroplane that incorporates new composite manufacturing technology, hybrid electric propulsion and an automated folding wing, which we developed and patented,” explains Lecce. “The intention was a short takeoff and landing (STOL) aircraft that is competitive with vertical takeoff and landing (VTOL) aircraft but offers more affordability. We believe this could be a personal aircraft operated from any surface and is an important possibility for future aeronautics and mobility.”

The SEAGULL short takeoff and landing aircraft features composite fuselage, tail and folding wing. The first prototype is completing in-water testing and the flying prototype is slated for testing by early 2021. Planned future developments include hydrofoils and hydrogen fuel cell propulsion. Photo Credit: Novotech.

The SEAGULL team has tested a hybrid propulsion system, built a first in-water prototype and began in-water testing in October. “After this testing is completed, we will then build a flying prototype within another few months,” says Lecce. “This is a very experienced team, comprising significant companies with more than 50 years of experience in general aviation.”

The SEAGULL flying prototype will feature a composite fuselage, tail and wing. “Again, we will push the application of automated manufacturing using AFP and resin infusion,” says Barile. “One of the main issues with composites using these processes is the cost of the materials. Indeed, what we are trying to do is to find also a combination of material and process that is more democratic in terms of cost.”

Related Content

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)