New Products: April 2018

CW’s monthly roundup of new products for the composites industry.

Share

Composite materials and innovations are constantly evolving. In addition to industry news, features, blog posts and podcasts, CW also maintains a comprehensive collection of product announcements provided by companies. This monthly roundup includes links to regular posts concerning the latest products of interest to the composites industry.

This month has seen innovations from Airtech, Analyswift, Arkema, Ashland, Azco, BÜFA Composite Systems, Coastal Enterprises Jetcam, Mahr, Metrology, MultiMechanics, Panacol, Porcher Industries and Techsil.

- Analyswift’s PreVABS preprocessor (for users of the VABS composite blade simulation software)

- Metrology’s new Artec Ray 3D laser scanner

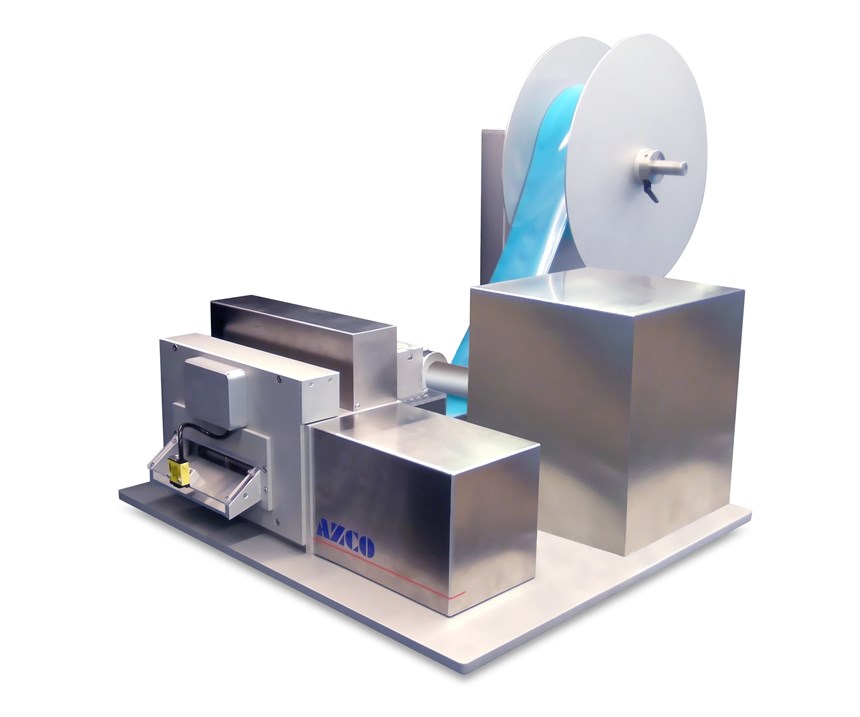

- A heat seal packing solution from AZCO

- New pre-cut tapes from Airtech

- Penloc GTN, a low odor methyl acrylate adhesive

- New 3D printing filaments based on PEKK and PVDF

- Vitralit UV 4802, a light curing adhesive for bonding high temperature resistant thermoplastics

- Ashland’s new Derakane resin

- Mahr’s expanded OPTIMAR 100

- New versions of a range of applications from JETCAM

- The MultiMech 18.0 simulation platform

- A line of conductive gelcoats from BÜFA

- A material selection guide from Coastal Enterprises

- A new lightweight para-aramid fabric from Porcher Industries

Related Content

-

IPSA acquires bonding adhesives based on MMA technology

IPS Adhesives (IPSA) introduces a line of adhesives using acrylate and MMA technology from L&L Products for the bonding of dissimilar materials such as metals and composites.

-

Pro-Set named official materials supplier for New York Yacht Club American Magic

Competitive sailing team prepares for the 37th America’s Cup beginning in August 2024 with adhesives, resins and laminate testing services for its AC75 monohull construction.

-

Pontacol thermoplastic adhesive films are well-suited for composite preforms

Copolyester- and copolyamide-based adhesive films eliminate the need for sewing threads or binders when stacking laminates while improving the final part’s mechanical properties.