New tooling paste enables complex pattern manufacture

Seaway Group (Begunje, Slovenia) is a well-known boat development company created in the early 1980s by Jernej and Japec Jakopin. Not only does the company design award-winning craft, like the Skagen 50 motor yacht, but it also performs contract engineering and produces tools and patterns to print.

Seaway Group (Begunje, Slovenia) is a well-known boat development company created in the early 1980s by Jernej and Japec Jakopin. Not only does the company design award-winning craft, like the Skagen 50 motor yacht, but it also performs contract engineering and produces tools and patterns to print. A recent Seaway project involved creating a front liner for the Windy 48 Triton by Windy Boats AS (Nedenes, Norway, a subsidiary of Periscopus AS in Oslo, Norway).

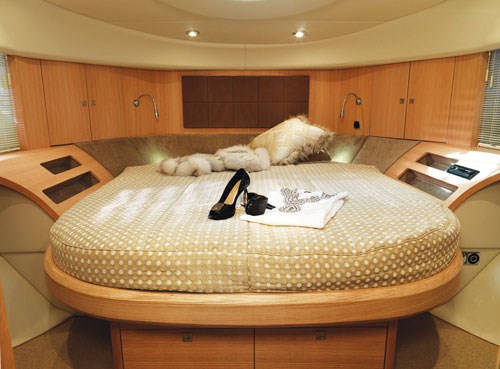

The front liner is a very complex part in the Triton’s forward cabin. It supports a raised platform bed that also includes built-in cabinetry. To make the highly detailed part, Seaway first had to make a pattern — it chose the new T-Paste 70-1 epoxy tooling paste from Gurit UK (Isle of Wight, U.K.). A substrate was built from bonded blocks of low-cost, high-density expanded polystyrene foam, then rough-cut using a 5-axis gantry CNC machine to a 15 mm/0.6-inch offset from the final mold line. T-Paste 70-1 was applied over the foam at a thickness of 20 to 25 mm (0.8 to 1 inch), using a meter/mix machine and application hose. Total application time was only 3.5 hours. After room-temperature cure, the paste was CNC machined to the final dimensions.

Andrew Harvey, Gurit’s formulated products manager, says the paste has excellent sag resistance on vertical surfaces, an important factor for the deep angles of the front liner pattern. It also is designed to be seamless when extruded in overlapping beads onto the foam substrate, resulting in fewer lines or defects after machining. Microspheres in the formulation reduce the paste’s density and make it easier to machine, as well, producing very little dust in the process, notes Harvey.

The completed pattern (bottom photo) was sanded, sealed, treated with release agent and used to create a fiberglass/polyester mold that, in turn, was the basis for the completed fiberglass part (middle photo). Seaway’s tooling manager Jernej Pristavec says, “The excellent handling and application properties of T-Paste 70-1 make it ideal for complex patterns like this one.”