Plant Tour: Composite Advantage

Composite Advantage supplies engineered fiber reinforced polymer (FRP) products including bridge decks, trail bridges, cantilever sidewalks, rail platforms, as well as waterfront structures such as fender protection systems, pilings and naval ship separators.

Recently CompositesWorld visited Composite Advantage LLC (Dayton, Ohio, U.S.) for a tour of its facility. The company supplies engineered fiber reinforced polymer (FRP) products including bridge decks, trail bridges, cantilever sidewalks, rail platforms, as well as waterfront structures such as fender protection systems, pilings and naval ship separators.

CW has reported on Composite Advantage’s projects for some time, and was thrilled at the opportunity to check out the facility. At the time of the visit, the company was working on FRP bridge deck panels for a project for the Nevada Department of Transportation’s (NDOT) which will create more than 30 miles of shared-use path along Lake Tahoe. (The project is discussed in detail in a blog post by Composite Advantage.)

This bridge panel fabricated by Composite Advantage is destined for a shared-use path along Nevada’s State Route 28 along Lake Tahoe.

According to Scott Reeve, president and CEO of Composite Advantage, a solution was needed that could be installed on uneven, rocky terrain. Also, Nevada’s State Route 28 provides the only access to a particular section of the Lake Tahoe coastline, so shutting down the road to pour concrete wasn’t a good option — the right solution would also need to afford quick installation.

“Environmental conditions and traffic concerns dictated a lightweight, prefabricated product,” says Reeve.

Composite Advantage’s FRP bridge deck product was chosen for the job. During the plant tour, CW got a peek at some of the panels in the making.

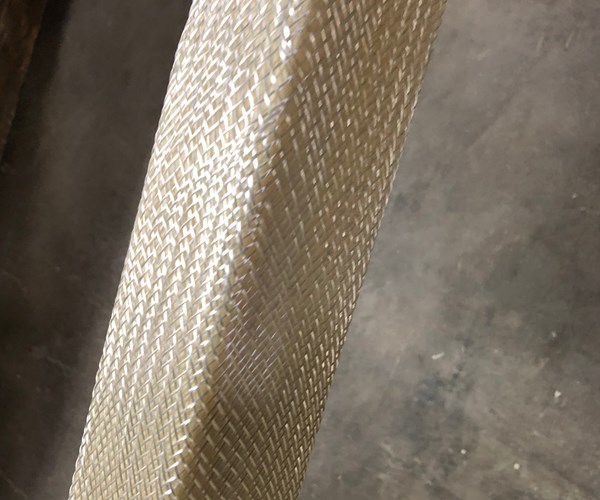

A cross-section of a Composite Advantage bridge deck panel shows the sections of lightweight core material that are encased in glass-fiber fabric and then infused with vinyl ester to create a section of FRP bridge decking.

In addition to the bridge decks, Reeve also explained the company’s work with waterfront structures. Composite Advantage’s offerings include composite pilings, fender systems and camels (which are bumpers that protect naval vessels).

“Our pilings are the ‘fence posts’ that support wales or guard rails in a fender system,” explains Reeve.

He indicated that piling systems are an area where FRP can make a huge difference, not just in terms of weight savings and corrosion resistance, but in terms of cost.

“We’re able to fabricate our pilings with a high strength-to-weight ratio which means we can make a very structurally efficient pile,” says Reeve. In a recent project in New Jersey’s Cape May Peninsula, the company’s FiberPILE FRP system was able to cut the number of piles needed for the structure in half, thereby offering cost savings. Composite Advantage met the necessary 250 kip-foot energy absorption impact load using 53 composite piles, ultimately replacing 141 original wooden piles.

The role of composites in infrastructure is at an interesting point. In August of 2018, bipartisan legislation was introduced in the U.S. aimed at encouraging research and use of innovative materials for infrastructure projects. Known as the Innovative Materials for America’s Growth and Infrastructure Newly Expanded (IMAGINE) Act, the bill seeks to lead decision makers involved in construction and infrastructure projects to consider innovative materials as an option. By educating about the benefits and properties the materials offer, infrastructure projects might be envisioned with the right material for the job.

With its experience working to offer solutions like FRP bridges and waterfront structures that offer high strength, corrosion resistance and improved material lifetime, Reeve says Composite Advantage is involved in those discussions in Washington D.C. and efforts to educate decision makers about the benefits of composites. And in the meantime, they’re creating and rehabilitating structures that stand the test of time. One might say Composite Advantage is a company working to build bridges in more ways than one.

Check out Composite Advantage’s blog post about the visit for more insights.

Related Content

CSub delivers one-piece composite truss bridge in Norway

EPC supplier has fabricated, transported and delivered a 42-meter composite bridge intended for pedestrians and bicyclists.

Read MoreCCG meets customer demand with StormStrong utility pole lineup

Additional diameters build on the portfolio of resilient FRP pole structures for distribution and light pole customers.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreSGL Carbon carbon fiber enables German road bridge milestone

A 64-meter road bridge installed with carbon fiber reinforcement is said to feature a first in modern European bridge construction, in addition to reducing construction costs and CO2 emissions.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More