Share

Rare is the composites manufacturing engineer, operations director or plant manager who has looked at his or her facility and not wished for the opportunity to do things differently — to improve material flow, optimize processes and replace waste with efficiency. Most of the time, such improvements are done in-situ, working with existing space. Occasionally, however, such improvements are done with a blank slate in a new, purpose-built plant that allows for a complete reconsideration of manufacturing operations.

Such was the case for San Diego-based Meggitt when it was given the opportunity to not only move out of the smaller, older space, but to create a new manufacturing space designed specifically for the materials and processes it uses. Along the way, the company learned much about itself, as well as about how people, resins, fibers and machinery can and should be organized to make parts now and in the future.

Meggitt San Diego is a composites fabricator within the larger, global Meggitt PLC aerospace group that, in addition to composites manufacturing, provides technology and solutions for avionics, braking systems, engine systems, fuel systems, fire protection, sensors, thermal management and more. The company has locations in North America, South America, Europe, Asia and Australia. The former San Diego facility, which CW toured and reported on in early 2015, was previously owned and operated by Cobham and acquired by Meggitt in late 2015.

San Diego operations were previously located in two buildings, with a total space of about 75,000 ft2. As with many composites fabricators, Meggitt San Diego’s business simply outgrew the old space. The company was given the opportunity to consolidate operations under one larger roof, also in San Diego, which it did in 2018. The new building is an expansive 120,000 ft2, with 93,000 ft2 of that devoted to manufacturing.

Designing the space

Meggitt San Diego operates 14 discrete “value streams,” or lines, that produce products. These products include, among others, munitions housings for flares for the F-35 fighter, cylinder sections for the Javelin anti-tank missile, spinner caps and spinner assemblies for Pratt & Whitney turbofan engines, and stators, guide vanes and exhaust flaps for the F-135 engine, which powers the F-35. Materials are exclusively hand-laid prepreg; processes are mostly compression molding, including the unusual multi-axis compression molding process, which is described below.

As Meggitt engineers and value stream leads looked at the new space it would occupy and considered how to best organize it, the first step was to evaluate product and work flow at the old facility. Where were the inefficiencies and how could they be either minimized or eliminated? Meggitt subscribes to the lean-based 3P philosophy, which focuses on production, preparation and process.

Because Meggitt produces discrete and unique products, each product manufacturing line has autonomy and could be evaluated individually. Looking at each manufacturing line through the 3P lens, Meggitt assessed product, material and personnel flow at its old facility. The company discovered that parts flow, in the old facility, from start of manufacture to finish, could be as long as 1 mile, which created time and effort waste, and introduced the opportunity for error. “Obviously we wanted to optimize this number,” says Dylan Mendoza, value stream manager at Meggitt.

Dana Forseth, director of operations at the San Diego facility, leads us out to the production floor of the new building. He says the vast and empty space that greeted Meggitt just a few months previously allowed engineers to completely re-think the physical layout of the manufacturing lines. Mendoza says Meggitt settled quickly on a U-shaped production line for each value stream, with raw material entering one end of the U and finished product exiting the other end. In between would be all of the people and equipment necessary for manufacturing, including ply layup in a cleanroom, compression molding, machining/finishing, inspection and quality control.

Forseth says that once the U-shaped lines were decided on, cross-functional teams created cardboard cutouts of the footprint of every piece of equipment that would be moved into the new facility — cutting tables, compression molding machines, CNC machines, inspection equipment, metrology equipment. These cutouts were laid in a variety of configurations to assess use of space, product travel distance, personnel travel distance and more. Forseth says 60 layouts were considered using this method.

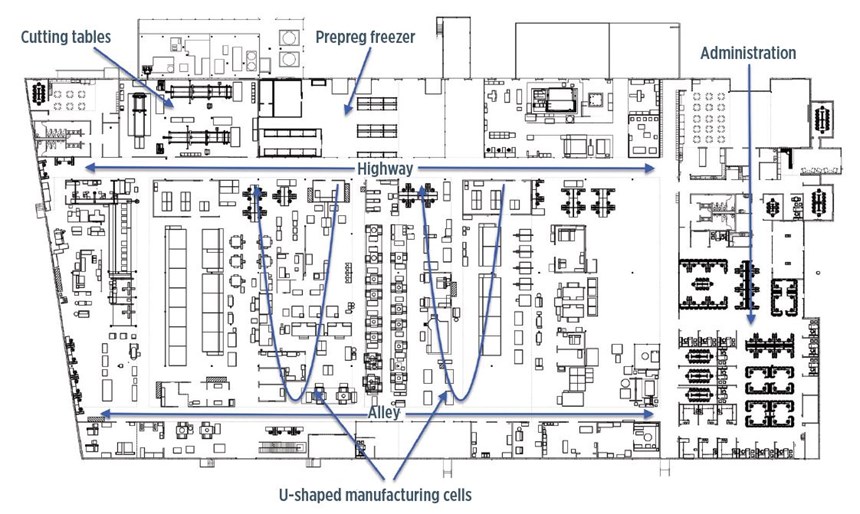

Parallel to this effort, Meggitt engineers also considered how these U-shaped manufacturing cells would be positioned inside the facility relative to other equipment and operations, including prepreg freezers, cutting and kitting, material receiving, product shipping and administration/management. The overall design Meggitt settled on employs geographical/map concepts. The entire production floor is bisected down the middle by a “highway,” a 20-ft-wide throughway running the length of the building that accommodates personnel. On one side of the highway is a cutting and kitting clean room, as well as a large walk-in freezer for prepreg storage. On the other side of the highway are the U-shaped manufacturing cells, each one identified by a sign (Stator 1, Javelin, etc.) over the layup room door associated with the cell. Behind the U-shaped manufacturing cells is the “alley,” through which Meggitt delivers materials needed for each cell (see floorplan image for details).

Immediately adjacent to the manufacturing area, separated by a wall of glass, the administration/management space employs an open concept, with several long desks and computer workstations for engineers and support personnel. Conference and meeting rooms surround this space. Clustered against the glass wall, and looking straight down the “highway,” are the open work spaces for the facility’s top managers, including Forseth, who are visible from almost anywhere in the plant. In short, all employees are easily seen and accessed. “We now have parts flow and we have line-of-site leadership, so everyone is where you need them to be,” he says.

Evolving composites manufacturing

The product lines that engendered the most growth at Meggitt San Diego are the stators and the munitions housings for the flares, both of which are associated with the ramp-up of F-35 production. The munitions housings, about 12 inches long and 1 inch in diameter, are made up of a carbon fiber/phenolic prepreg and compression molded in four Carver Inc. (Wabash, IN, US) compression molding machines. They are finished on two Haas Automation (Oxnard, CA, US) CNC machines, followed by post-cure in three ovens. Subsequent quality control and metrology is done by a Hexagon Manufacturing Intelligence (North Kingstown, RI, US) CMM system. Forseth says current throughput in this cell is 128 flares per day, and capacity can be easily increased; there is room for four to six more presses and one more CNC machine. The product flow of the flares is the one that, in the old facility, was a mile long. Here, in the new plant, it’s just 1,000 ft.

The most intriguing manufacturing process at Meggitt San Diego’s composites site, and the calling card of the facility, is the multi-axis compression molding used to fabricate the F-135 stators. These complex parts are manufactured with a carbon fiber/polyimide prepreg in complex multi-part molds that, when closed, are cube-shaped (or, six-sided). These molds are placed into one of eight (with five more coming) multi-axis compression molding machines, designed by Meggitt and manufactured by TMP, a Division of French (Piqua, OH, US). What makes the machines unusual is that they provide compression and heat to all six sides of the mold (hence, multi-axis).

The TMP machines featured in the new facility are the latest iteration of the multi-axis technology installed in the old Meggitt facility. The new units, says Forseth, feature easier mold loading, are safer, have upgraded hydraulics, offer better temperature regulation and provide better process control. The updates result in tighter tolerances, higher yields and better product quality. After molding, the stators are demolded, sandblasted and then deflashed by hand. Forseth says Meggitt is evaluating automated deflashing systems to reduce touch labor on the products.

Freezing, cutting, kitting, QC and Mexico

Prepreg storage at Meggitt is provided by two walk-in freezers. The largest is used to store full rolls of prepreg and is managed manually on a first-in/first-out (FIFO) basis. The second, smaller, freezer is used to store prepreg kits.

Prepreg cutting and kitting at Meggitt is performed in a two-room enclosure adjacent to the freezers. It houses one 30-ft American GFM (Chesapeake, VA, US) cutting table, with two more to be installed soon. The table features an ultrasonic cutter that can cut three to five plies simultaneously, has five spools for prepreg feeding, and is integrated with a FARO Technologies (Lake Mary, FL, US) laser projection system to aid manual ply sorting. Forseth says the waste rate on the table is 15-18%; it operates almost 24/7, particularly for the stators, which require 400 plies per part.

Operations management at Meggitt San Diego relies on daily layered accountability (DLA), a paper- and bulletin board-based system located on the manufacturing floor at the end of the highway. It is designed to give floor employees and managers easy access to manufacturing performance metrics. Under this system, managers start each day with a stand-up meeting at the DLA boards where performance metrics are reviewed, assessed and prioritized. Under the DLA system, material, production, quality and safety defects/challenges are categorized by severity (DLA1, DLA2, DLA3, DLA4), with specific actions and remedies prescribed for each level. Forseth says the DLA system provides a great tool for everyone at Meggitt to easily and quickly see and assess what the manufacturing challenges are. “We walk the safety talk here,” he says.

Just prior to Meggitt acquiring the San Diego facility from Cobham in 2015, Meggitt also acquired EDAC, a composites fabricator with locations in Erlanger, KY, US, Cincinnati, OH, US, and Saltillo, Mexico. Those sites are now being aligned with Meggitt San Diego for commercial composites fabrication work. For all commercial composites manufacturing projects, says Forseth, the San Diego and Erlanger facilities will focus on new product integration and low-rate production, with full-rate production provided by a 125,000-ft2 facility in Saltillo. One of the old San Diego buildings will be retained by Meggitt for new business expansion.

Related Content

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More