Virgin Hyperloop One’s XP-1 test pod on display at COSI (Columbus, Ohio, U.S.). CW Photo | Scott Francis

Since SpaceX (Hawthorne, Calif., U.S.) founder and CEO Elon Musk published his Hyperloop Alpha white paper in 2013, the concept of a Hyperloop system has captured the imagination of the public as a possible future mode of transportation. Meant to that could compete with commercial continental air travel between cities separated by approximately 900 miles or less,. tThe concept envisions using a capsule — also called aor “pod” — to transport passengers and freight at high speeds through a tube or series of tubes. The tubes are designed to lower air resistance using that use a partial vacuum to lower air resistance, and. tThe pods also have the potential to reduce or eliminate friction based on a few using under-development different technologies ranging from magnetic levitation to air-casters. It is estimated that Hyperloop vehicles could reach speeds exceeding 1,000 km/hr.ilometers per hour, or somewhere between 600 and 700 mph.

Musk’s Hyperloop concept was released as an open-source design meant to encourage others to build upon the ideas and further development of the transportation system. The concept has inspired several commercial companies and student teams to create Hyperloop prototypes. While Hyperloop as a transportation system might seem similar in some respects to trains, lightrails or other rail-based modes of mass transit, because of the low air pressure and extreme speeds, Hyperloop pods actually have more in common with airplane fuselages. Traveling in a Hyperloop tunnel exposes the pods to speed and air pressure conditions similar to those at 200,000 feet above sea level. In order to handle the demanding loads, high speeds and internal pressures, the pods require materials that combine stiffness and strength with and light weight. Most of the prototype vehicles that have made their debut have employed carbon fiber composites in some way.

A built-in proving ground

SpaceX continues to support the concept through its Hyperloop Pod competition, which has been held annually at the company’s Hyperloop test track in Hawthorne, Calif. since its inception in 2015.

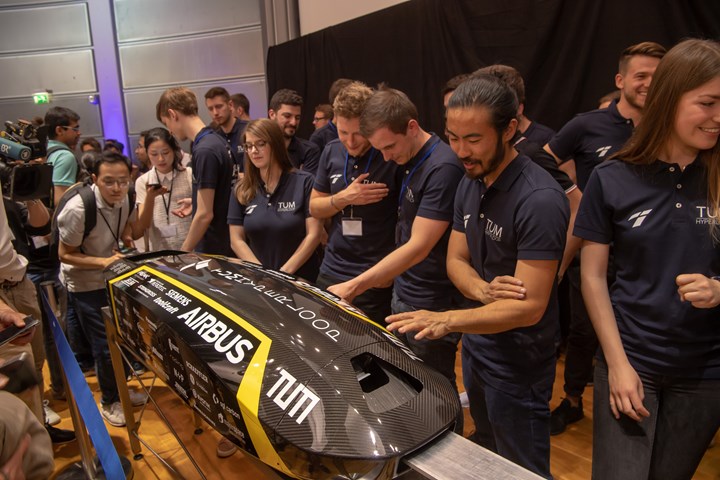

In 2019, SpaceX held its fourth Hyperloop Pod competition. Twenty-one 21 teams were selected, with four qualifying for the final competition on July 21. The four teams in the final competitions included Swissloop of ETH Zürich (Zürich, Switzerland), EPFLoop of Ecole polytechnique fédérale de Lausanne (Lausanne, Switzerland), Delft Hyperloop of Delft University of Technology (Delft, Netherlands) and TUM Hyperloop of the Technical University of Munich (TUM, Munich, Germany). TUM Hyperloop, formerly known as WARR Hyperloop, won the competition for the fourth time in a row, setting a new record with a top speed of 463 km/hr. (288 mph). The team might have further exceeded the record speed, but its pod suffered some damage due to derailment of one of its propulsion modules, and was forced to brake early.

TUM Hyperloop won SpaceX’s 2019 Hyperloop Pod Competition in July, setting a new record with a top speed of 463 km/hr. (288 mph). Source | TUM Hyperloop

TUM Hyperloop constructed its pod using carbon fiber prepreg from SGL Carbon (Wiesbaden, Germany). Based on design and material optimizations, the carbon fiber component of the current pod weighs around 10% less than that of the team’s previous model (5.6 kilograms compared to 6.1 kilograms).

“It’s impressive to see what the [TUM team] achieved in such a short amount of time,” says Dr. Christoph Ebel, head of the Lightweight and Application Center at SGL Carbon. “From the idea, to prototype development, to the finished part, the team only needed a few months. Behind the Hyperloop pod design are numerous innovative ideas based on modern lightweight construction, challenging to realize technologically.”

The Hyperloop Pod competition helps foster constant redesign and innovation. The teams rework their pod designs each year and receive support from material suppliers and technology companies.

Swissloop’s second 2nd place winning pod — the Claude Nicollier, named after the first Swiss astronaut, — is run by a linear induction motor that which itself prompted an innovation award from SpaceX. The pod’s chassis comprises is comprised of carbon fiber, resulting in a weight of only 200 kilograms.

EPFLoop’s prototype features a carbon fiber composite exterior protective structure based on a U-shaped skeleton with the motor on the inside and battery packs on the outside. A small pressurized chamber on the top of the pod protects the electronic components and the entire pod is covered in a carbon fiber skin. According to team leader Lorenzo Benedetti, EPFLoop used biaxial prepregs XC411 and RC200 from Gurit (Wattwil, Switzerland), as well as the company’s M80 and M200 foams.

Delft Hyperloop ’s Atlas 02 pod comprises is comprised of a full composite chassis and carbon fiber battery case. The vehicle was manufactured with automation technology and support from Airborne (The Hague, Netherlands) using Toray Advanced Composites’ (Morgan Hill, Calif., U.S.; Nijverdal, Netherlands) uni-directional carbon fiber epoxy-based prepregs, supplied from its European Centre of Excellence (Langley Mill, Nottingham, U.K).

While the student pods continue to break speed records, reaching the kinds of speeds needed to commercialize Hyperloop has yet to be accomplished. The consensus is that in order to reach the 600-700 mph potential of Hyperloop, the tracks need to be long enougher to allow the pods to reach top speed. SpaceX’s current track is approximately one mile long.

Following the competition, SpaceX announced plans to build a new Hyperloop tunnel to be used for the 2020 pod competition. According to a Tweet from Musk, the new vacuum tunnel will be 10 kilometers km (roughly 6 miles) in length and include a curve.

Passenger pods

Several commercial Hyperloop companies not affiliated with SpaceX have also been working to develop passenger pods, set up test tracks and garner support for proposed routes. Virgin Hyperloop One (VHO, Los Angeles, Calif., U.S.) and Hyperloop Transport Technologies (HyperloopTT, Culver City, Calif., U.S.) are arguably the two leaders in the race, with TransPod (Toronto, Canada) also in the running.

VHO’s Hyperloop uses electric propulsion to gradually accelerate pods. A propriety magnetic levitation system allows them to glide at airline speeds through low-pressure tubes. VHO’s test pod, the XP-1, is constructed of a structural aluminum chassis surrounded by a carbon fiber shell. The vehicle, which is not designed for passenger use, has achieved speeds of up to 240 mphmiles per hour on VHO’s 500-meter test track, known as DevLoop (Las Vegas, Nev., U.S.).

VHO’s test pod, the XP-1, is constructed fromis comprised of structural aluminum and a carbon fiber shell. CW Photo | Scott Francis

According to Ryan Kelly, marketing manager for VHO, the design for the Hyperloop capsule is approached much like that of an airplane fuselage. The stress of loads, extreme speeds and internal air pressure all have to be taken into account for the vehicle design and the materials that are employed. While VHO has not yet developed a passenger capsule, Kelly expects that composites will play a role in the design, just as they have in the test pod.

HyperloopTT boasts the first full-scale Hyperloop passenger vessel. The capsule, Quintero One, is constructed almost completely out of a composite material HyperloopTT calls Vibranium (a nod to the fictional material conceived by Marvel Comics for Captain America’s iconic shield). The material is, in fact, a specially made dual-layer smart composite material created using carbon fiber and embedded sensors. HyperloopTT’s 32-meter-long capsule is made up comprised of 82 carbon- fiber composite panels. It was built at the aerospace facilities of HyperloopTT’s partner Airtificial (Madrid, Spain), a company specializing in the design, engineering and manufacturing of sensor -enabled structures made of composite materials. Airtificial was formed by the merger of Carbures (El Puerto de Santa María, Spain), a composite structure manufacturer for the transportation and infrastructure sectors, and civil engineering company Inypsa (Madrid, Spain) in 2018.

HyperloopTT’s passenger capsule features a proprietary dual-layer smart composite material created using carbon fiber and embedded sensors. Source | Hyperloop Transport Technologies

Like VHO’s XP-1, TransPod’s vehicle design is also similar to an airline jet fuselage and is driven by magnetic propulsion. The passenger pod structure and shell are being co-developed by Blackshape Aircraft (Monopoli, Italy), which produces carbon- fiber composite aircraft for the general aviation sector.

“Composites form certain parts (but not all) of the structure,” says Ryan Janzen, co-founder and chief technical officer CTO of TransPod. “It’s all about being strategic with the different materials.”

TransPod is working with carbon fiber aircraft manufacturer Blackshape Aircraft to develop its passenger pod. Source | TransPod

Hyperloop infrastructure

In addition to Aside from the capsules, there is also potential for composites use in the Hyperloop tubes themselves. Composites are, of course, Aside from being lighter than traditional materials while still being able to meet structural requirements, but they are also composites are less susceptible to corrosion and are less sensitive to temperature change, making problems caused by thermal expansion less likely. While many of the currently existing Hyperloop test tracks have, for the most part, been built of either steel or concrete, there are companies exploring the use of new materials.

HyperloopTT’s tubes are a combination of steel, concrete and carbon fiber. Source | Hyperloop Transportation Technologies

HyperloopTT’s tubes, like its passenger capsule, are manufactured by Airtificial and are a combination of steel, concrete and sensor-embedded carbon fiber. In 2018, Airtificial signed a contract for 19.9 million euros with HyperloopTT for manufacturing a 5-kilometer pilot section of Hyperloop tube to take place after analysis of tube prototypes installed at HyperloopTT’s research facilities in Toulouse, France.

Composites play a role in TransPod’s tube design as well:. “The TransPod infrastructure includes a tube, and many other materials inside and outside the tube segments,” says Ryan Janzen, co-founder and chief techical officer of TransPod. “The materials include metals, polymers and some composites. All of these parts work together to manage the loads, dynamics, pressures and propulsion forces.”

“The TransPod infrastructure includes a tube, and many other materials inside and outside the tube segments,” says Ryan Janzen, co-founder and CTO of TransPod. “The materials include metals, polymers and some composites. All of these parts work together to manage the loads, dynamics, pressures and propulsion forces.”

Meanwhile, Delft Hyperloop and Jules Dock (Rotterdam, Netherlands), a developer and manufacture of a range of composite products, are collaborating on research into the possibility of composite tubes for Hyperloop based on a concept Jules Dock is developing for sea-based windmill towers manufactured through continuous filament winding (CFW). Delf Hyperloop and Jules Dock stated on the blog Hyperloop Connected that filament winding might enable pop-up factories to produce the composite tubes on site during the building of Hyperloop routes.

Commercial Hyperloop

While development of test pods and tracks are underway, Hyperloop companies have has also been working to drum up support for proposed routes both in the U.S. and around the world.

VHO plans to begin work in December of 2019 on a track in India that would connect Mumbai and Pune, with the aim of reducing travel time between the cities from 3-4 hours (including traffic) to 25 minutes. The company has also announced plans to conduct a study with the aim of to building a long-range Hyperloop test track in Saudi Arabia. According to VHO, the study will focus on King Abdullah Economic City (KAEC), located 100 kilometers north of the Red Sea port of Jeddah. The proposed project includes a 35-kilometer test track and will create opportunities for the development of Hyperloop technologies and expertise in the region.

In the U.S., Hyperloop companies are hoping to build onoff of the momentum of U.S. Secretary of Transportation Elaine Chao’s Non-Traditional and Emerging Transportation Technology (NETT) Council. NETT was launched at the South by Southwest Conference (SXSW, Austin, Texas, U.S.) in March, and aims to support new and innovative transportation projects like Hyperloops and self-driving cars.

VHO is conducting feasibility studies and environmental impact studies (EIS) for numerous U.S. routes, with its eye on a Chicago-Columbus-Pittsburgh corridor in the Midwest, a St. Louis to Kansas City route in Missouri, and a Dallas to Fort Worth corridor in Texas. The company visited Capitol Hill in Washington D.C. in June to present its technology to members of Congress and federal stakeholders. In August, VHO launched a roadshow across the U.S., with stops in Missouri, Texas and Ohio, showcasing its XP-1 test pod in an effort to connect with communities, and to educate local and state governments on how Hyperloop can help advance the country’s transportation capabilities.

“We are now seeing the groundswell of support that’s needed to realize the Hyperloop revolution with the formation of the NETT Council and support from lawmakers across the country,” says Jay Walder, CEO of Virgin Hyperloop One. “As Hhyperloop moves toward reality, it’s becoming clear that it will not only transform how we travel but also create an entirely new industry with thousands of new jobs for Americans.”

USDOT officials visit HyperloopTT’s research facility in Toulouse, France. Source | Hyperloop Transportation Technologies

Meanwhile, HyperloopTT met with officials from the U.S.nited States Department of Transportation (USDOT, Washington, D.C., U.S.) in June at HyperloopTT’s research facilities in Toulouse, France. USDOT officials were reportedly able to see the company’s full-scale track system as it undergoes optimization and integration prior to the construction of a commercial system in Abu Dhabi. The company has presented a technical overview of Hyperloop technology and certification guidelines completed by global testing, certification, inspection and training provider TÜV SÜD (Munich, Germany) to the USDOT as well as the European Commission (Brussels, Belgium). With tubes assembled and pumps installed, HyperloopTT says it is now beginning preparations of its full-scale passenger capsule for human trials in 2020.

“Not only are we building the only truly full-scale, insured and safety certified system in the world,” says Dirk Ahlborn, CEO of Hyperloop Transportation Technologies. “We are advancing our efforts to move the Hyperloop forward by sharing our technological experience and our perspective on regulatory frameworks.”

“We are moving ever closer to the moment when we will move people in the Hyperloop for the first time,” adds Bibop Gresta, cChairman of Hyperloop TT. “And by sharing our insights with our government colleagues in the United States and Europe, we are furthering our goal of creating the safest and most efficient form of transportation the world has ever seen.”

Interior of Virgin Hyperloop One’s DevLoop test track in Nevada. Source | Virgin Hyperloop One

Analogous to the way Hyperloop is meant to gradually accelerate to airliner-like speeds, the vision for Hyperloop seems to be gaining momentum. Of course Hyperloop has its detractors — concerns are continually raised about safety of the tubes, problems with thermal expansion and susceptibility to terrorist attack, to name a few. Nevertheless, the original open source idea of Hyperloop, meant to spark innovation, competition and collaboration, seems to have achieved its goal. Companies and research organizations are working to figure out the answers to all of those very legitimate concerns.

Sir Richard Branson, founder of the Virgin Group, believes “we could see a Hyperloop in the U.S. in years, not decades.” If that’s the case and Hyperloop does reach full speed, the composites industry will most certainly continue to be involved and ready to support it.