Public transit: Modular composites update Sao Paulo ferries

When the Brazilian state of São Paulo, through its state-controlled company DERSA, funded new composite superstructures for 12 existing car ferries, Barracuda Advanced Composites (Rio de Janeiro, Brazil) specified materials and engineered the new design.

The Brazilian state of São Paulo recently undertook a project, through its state-controlled company DERSA, to improve public transportation infrastructure. Formed in 1969, DERSA manages state highways and operates ferry boat services along 622 km/383 miles of coastline. Scheduled for completion this year and intended to reduce commute times by 30 percent, the project involved refitting 12 car ferries and replacing their steel superstructures with composite constructions. DERSA engaged distributor Barracuda Advanced Composites (Rio de Janeiro, Brazil) not only to specify and supply the composite materials, but also to engineer the superstructure design.

Barracuda’s CEO Jorge Nasseh says the project called for a composite deck, side-rail assemblies and a topside operator cabin as prefabricated, 3m by 2.4m (9.75-ft by 7.8-ft) flanged panels, which could be assembled and bolted onto the existing steel hulls. The modular design allows the addition of panels to fit the various ferry lengths, which range from 35m to 48m (114 ft to 156 ft).

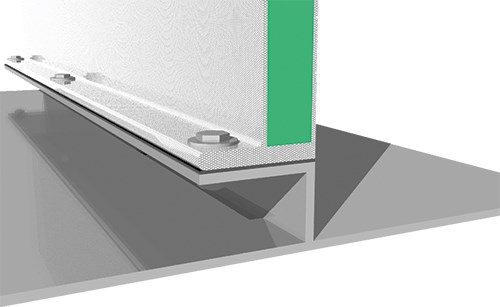

Panels are sandwich constructions, but flanges are solid (uncored) to optimize assembly by adhesive bonding and mechanical fastening. Larger, 75-mm/3-inch thick flanges are used where panels are bolted to the hull’s steel flanges (see computer rendering). Multiaxial fabric from Owens Corning Composite Solutions Business (Toledo, Ohio) forms the faceskins, over a polyvinyl chloride (PVC) Divinycell H80, 32-mm/1.3-inch thick core supplied by Diab International AB (Laholm, Sweden). The core is grooved by Barracuda in a proprietary manner that Nasseh says improves infusion flow. The resin is an orthopolyester formulated by Ashland, LLC (Columbus, Ohio). He adds that the infusion process was modeled prior to finalization of the design using Polyworx software from PolyWorx (Nijverdal, The Netherlands). To meet transportation requirements, each panel is overcoated with an Ashland fire-retardant polyester.

“The new composite design will allow overall weight reduction, fuel economy, less maintenance cost,” says Nasseh, “and offers a better cosmetic design.”

Related Content

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.