Re-inventing the RHIB: Shock Mitigation

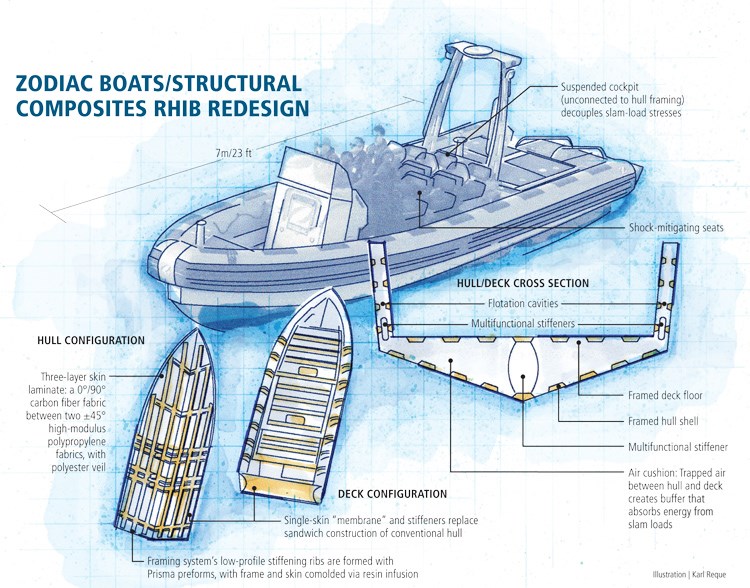

The U.S. Navy’s search for a lighter, load-absorbing rigid-hulled inflatable boat may end with this unconventional design.

Engineering Challenge:

Increase the payload capacity of small seacraft by significantly reducing the hull structural weight while improving shock absorption to minimize operator and crew exposure to wave impact and injuries.

Design Solution:

A shift from a rigid sandwich structure to a shock-absorbing membrane design — a coinfused low-section preform framing and a single-skin composite laminate — reduces weight by 20+ percent.

Aboard most U.S. Navy ships, rigid-hulled inflatable boats (RHIBs) provide a quickly launched, speedy and maneuverable means of short-range insertion and extraction for special ops forces and transport for resupply, patrol and surveillance missions in coastal and inland waterways. But demand for greater payloads — additional troops, equipment, weapons and armor — and the resulting weight increase puts RHIBs and their personnel at greater risk by reducing the boat’s speed and agility. Worse, a payload increase isn’t possible if extra weight exceeds the capacities of the davits (small cranes) used to lower the RHIBs into the water.

To address this, the U.S. Navy issued a Small Business Innovation Research (SBIR) solicitation (see p. 41 for notice) for materials and designs that could reduce RHIB hull weight by 25 to 30 percent, yet boost payload capacity by 1,000 to 2,000 lb (about 450 to 910 kg).

In response, Scott Lewit, president of Structural Composites Inc. (Melbourne, Fla.), suggested a shift from the rigid sandwich construction used in the majority of small watercraft to a new, lightweight hull-and-deck construction with a single-skin membrane design and low-section framing. “We want to take advantage of the hull laminate’s in-plane properties as opposed to its out-of-plane properties,” explains Lewit. “Using a conventional approach, the primary loads the laminate experiences are flexural loads,” he continues. “The membrane boat has a single skin that is not flexurally stiff.” It functions like fabric-covered wooden wings once did on vintage aircraft. “The fabric is flexible and acts as a membrane, transferring loads to the frames in the wing structure,” says Lewit.

The benefit is enormous. Although a laminate under bending strain might break under a force as small as 100 to 200 lb (45 to 91 kg), Lewit points out that the same laminate under tension might withstand thousands of pounds of force. “By making the laminate thin and not flexurally rigid, it behaves more like a skin, allowing us to transfer the loads to the framing with a lighter structure. Also, the deflection of the laminate and the low-section framing help absorb shock energy.”

Shock mitigation has become a major thrust. Shock loads occur when a fast-moving boat comes out of the water, partially or completely, and then slams against the water surface as it reenters. “These loads are a serious problem to boat operators and crew,” stresses Lewit. “Short term, it is common to experience strained backs, knees, and ankles or have blood in the urine.”

New design elements mitigate these effects. The cockpit is suspended — not connected to the hull framing — to decouple the stress pattern and more effectively cushion the occupants. Further, an air cushion has been designed into the space between the hull and the deck to absorb slam loads. These elements, combined with shock-mitigating seats, should result in a 25 percent reduction in peak G loads, projects Lewit.

A new elastomeric coating, the marine version of a truck bed liner, trademarked Sharkskin, replaces traditional gel coat on the hull skin. “The large deflections the laminates will see are too much for conventional gel coats,” says Lewit. “Gel coats only stretch approximately 1 percent before breaking. The Sharkskin is an elastomer, and while we are looking at different formulations, most have strain to failure rates in excess of 200 percent.”

Structural Composites partnered with Zodiac Boats (Stevensville, Md.) to develop single-skin designs for RHIB platforms. Phase I of the project — to demonstrate the feasibility of material and structural concepts — was completed in December 2009, and Phase II was awarded to the group in December 2010.

While the Phase II project was in development, Structural Composites formed a Phase III team and submitted a proposal to the highly competitive Defense Logistics Agency’s Industrial Base Innovation Fund (IBIF). Advanced Technology International (ATI, Charleston, S.C.), which manages the Navy Center of Excellence for Composites, took the management lead, and Structural Composites took the technical lead. Phase III expands the Phase II effort by including the expertise of Lockheed Martin (Bethesda, Md.) and adding Brunswick Corp. (Lake Forest, Ill.) to the manufacturing team. The platforms were expanded to include an 8.5m/28-ft RHIB (Brunswick) and an advanced 11m/36-ft RHIB (Zodiac). Phase III funding came in late September 2010, so Structural Composites was in the rare position to have Phase III funding prior to Phase II.

In the Phase I SBIR, the companies developed three designs (one low-cost and two advanced) for 7m/23-ft RHIB platforms. The designs reportedly offer a laminate weight reduction ranging from 40 percent to 60 percent, compared to conventional rigid construction using vinyl ester resin. Phase II funds the refinement of these designs and the construction and evaluation of the low-cost 7m RHIB. The Phase II option, if elected, would fund the construction of the advanced 7m RHIB. For the IBIF project, the team is designing a low-cost 8.5m RHIB and an advanced 11m RHIB, both of which will be constructed and then given to the Navy for evaluation.

The low-cost, single-skin design incorporates E-glass fiber and vinyl ester resin, and the advanced single-skin uses lightweight Innegra high-modulus polypropylene (HMPP) fiber from Innegrity LLC (Simpsonville, S.C.) with either an E-glass fiber core or a carbon fiber core. Lewit believes both the low-cost and advanced designs will be viable options, depending on the application.

Combining portable technologies

Some design elements had been in the works at Structural Composites for years. The company began to develop low-section framing for a foreign-built RHIB in the 1990s. A suspended cockpit design first appeared in a stunt boat at a major theme park, and experiments with and patents for its Sharkskin technology preceded the SBIR contract. But the air cushion was new to the RHIB redesign, inspired by an event during tests of an instrumented 20-ft/6m Proline boat. “I was collecting data during wave impacts, and at one point the boat went airborne. Upon landing, I watched as every cup holder in the boat popped like a cork due to the air pressure resulting from hull deflection,” he notes. “The idea behind our concept is to harness this effect. We want to drive pressure into the hull and create a way for the boat to breathe. Ideally, we want the boat to be pressurized prior to impact. As the wave impact is occurring, we want it to vent and then recharge in time for the next impact.”

Co-infusion of frame and skin

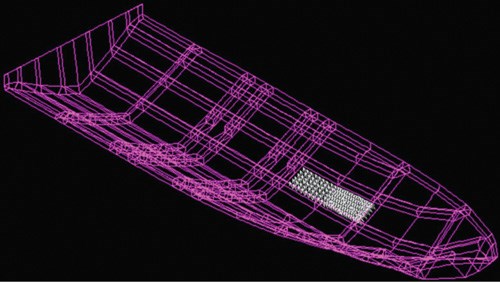

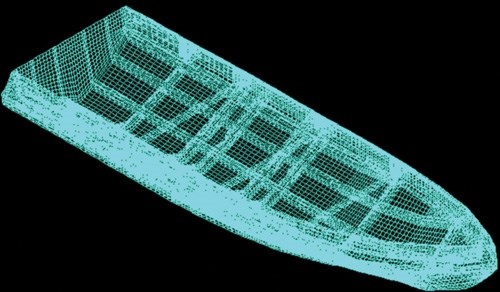

To optimize fabrication efficiency, closed molding techniques enable comolding of the hull skin and the low-section framing (see drawing, at right). “Resin infusion is being used to keep the process in control and maintain low weight,” says Lewit. “The challenge is scaling up the new material systems and process from the laboratory onto the manufacturing floor.”

Using existing molds, Structural Composites first places the laminate stack in the mold. Engineered as a three-layer laminate, the skin for the most advanced design consists of a layer of bidirectional (0°/90°) carbon fiber fabric between two layers of Innegra HMPP fiber that has been converted into a ±45° fabric at Vectorply Corp. (Phenix City, Ala.). A lightweight polyester veil is attached. The low-cost variation differs in that it has a thinner skin reinforced with E-glass fiber.

“The Innegra is being used to reduce weight and provide toughness,” says Lewit. “It’s not a very stiff fiber, so having it on the surface of the laminate allows for easier transition to membrane tension. The carbon then takes the majority of the load in-plane.”

The framing system relies on low-profile stiffening ribs attached to the skin and incorporates Prisma composite preforms from Structural Composites’ sister company Compsys Inc. (Melbourne, Fla.). “Prisma preforms are one of the enabling technologies of our design,” explains Lewit. “As a COTS [commercial off-the-shelf] solution, it allows for a cost-effective way to move from sandwich construction to single-skin construction,” he adds. (Prisma preforms were employed on the Navy’s redesigned Mark V Special Operations Craft. See “Learn More,” at right) and are widely used in the recreational marine arena.

The preforms combine a polyurethane foam core bonded to a polyester tie veil. A reinforcing fabric — E-glass or carbon, depending on the design variation — can be mechanically attached to the nonwoven polyester fabric. After the preforms have been placed, the framing and skin are bagged and co-infused with vinyl ester or epoxy resin and cured.

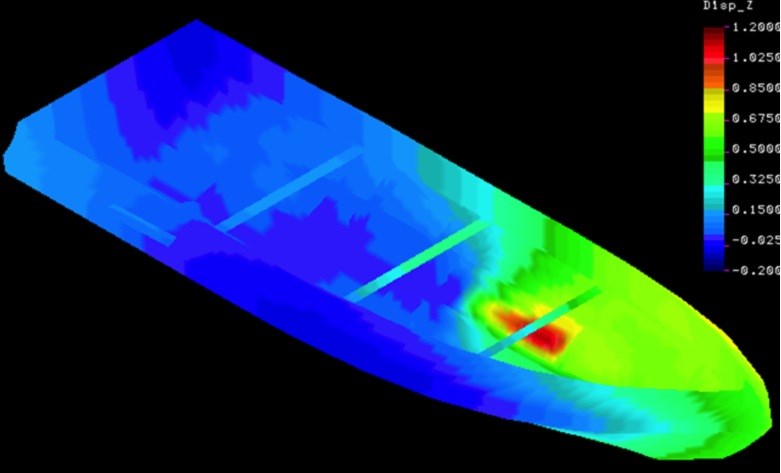

Conventional formula-based design methods, widely used in the marine industry, didn’t work on this project, Lewit recalls. “We turned to FEA [finite element analysis] modeling to see how the structure would behave.” The company uses COSMOS FEA software from Structural Research and Analysis Corp. (SRAC, Santa Monica, Calif.).

The RHIB experiences tremendous stress from running, wave-slam, hoist, gun-mount and transport loads. “In the case of the [8.5m design], a fully loaded boat can weigh up to 11,000 lb [4,990 kg], and in heavy seas, the hull can see significant loading,” says Lewit. “FEA allows us to identify areas where we need to refine the design, as well as areas where we need to do subscale testing.”

Current status, future possibilities

Structural Composites and partners have funding to build three boats, and the Navy has a Phase II option for a fourth boat. Earlier in the year, the company was awarded $245,000 through the Florida Research Commercialization Matching Grant Program to boost its lightweight boat technology. The team is in the design phase of the low-cost variation. Coupon testing is underway. “We expect to have the low-cost versions of the [8.5m] and 7m RHIBs, as well as an 11m advanced boat, produced and evaluated in the next year,” says Lewit.

But Lewit sees potential applications for aspects of the new RHIB technologies elsewhere and considers all of them portable. “They can be used by themselves or in conjunction,” he explains. “For example, a recreational builder may want to make a flatter-bottomed small boat to improve fuel efficiency and reduce the required engine size.” The framed construction combined with the suspended cockpit could do that as well as deliver a smoother ride in the waves.

Future applications could include larger naval ships, and Lewit is guiding lightweight single-skin technology into the recreational boating industry. Further, he reports, “We have made a major breakthrough in lightweight structures with regard to the RV industry, and we hope to be impacting this market in the next 24 months.”

__________________________________

SBIR Rights Notice (Dec 2007):

These SBIR data are furnished with SBIR rights under Contract No. N00024-11-C-4100 subject to the SBA/SBIR policy directive of September 24th, 2002. For a period of 4 years, unless extended in accordance with FAR 27.409(h), after acceptance of all items to be delivered under this contract, the Government will use these data for Government purposes only, and they shall not be disclosed outside the Government (including disclosure for procurement purposes) during such period without permission of the Contractor, except that, subject to the foregoing use and disclosure prohibitions, these data may be disclosed for use by support Contractors. After the protection period, the Government has a paid-up license to use, and to authorize others to use on its behalf, these data for Government purposes, but is relieved of all disclosure prohibitions and assumes no liability for unauthorized use of these data by third parties. This notice shall be affixed to any reproductions of these data, in whole or in part.

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreRead Next

Composites take the hit in U.S. Navy patrol boat

New carbon/Kevlar composite hull and deck provide impact-absorbing solution to crew injury problems caused by severe vertical acceleration of previous high-speed, all-metal patrol boat.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More