Report from IBEX 2015

As always, IBEX supplied new products, processes and education, not only to boatbuilders, but to the composites industry overall.

The 2015 Intl. BoatBuilders’ Exhibition & Conference (IBEX) was held Sep. 14-16 in Louisville, KY. The show drew 4,700 attendees and 545 exhibitors, 110 of which were new to IBEX. The Composites Pavilion featured almost 80 different companies as well as the 3D Digital Workshop — highlighting Stratasys and Cincinnati Inc. (see Editor’s Picks at right) — and the new Future Materials exhibit, co-curated by Professional BoatBuilder magazine and CompositesWorld.

TOP PHOTO: The KittyHawk unmanned aerial vehicle (UAV) can be seen in the background fabricated by VX Aerospace using Carbon Conversions’ recycled carbon fiber nowoven mat. BOTTOM PHOTO: Materials Sciences Corp. demonstrates the vibration cancelling of COUNTERVAIL in marine boom structures (left) while IBEX attendees peruse dozens of new products in the FUTURE MATERIALS exhibit. SOURCE: CW.

Future Materials featured a collection of the latest composite materials and process technologies from around the world. The goal was to offer IBEX attendees the opportunity to interact with cutting-edge composite products from a wide range of industries — aerospace, automotive, sporting goods, etc. — that they might not normally get to see.

Each station within the exhibit showed a product and/or part along with a display card describing the new technology and its potential for revolutionary impact in improved composite strength & stiffness, aesthetics, processing, multifunctionality and/or sustainability. A full list of the companies and products showcased with links to additional information is at www.ibexshow.com/futurematerials .

Seminars

Composites were also featured in the IBEX 2015 seminar line-up:

|

Chris Moody, NDT Systems Inc. (Huntington Beach, CA) Ed Green, Arcadia Aerospace Industries (Punta Gorda, FL) |

||

|

Al Horsmon, Horsmon & Assoc. (Three Rivers, MI) Tom Gast, Scott Bader-ATC (Taylorsville, NC) |

||

|

Belle Blanding, Composites Consulting Group (DeSoto, TX) Scott Lewit, Structural Composites Inc. (West Melbourne, FL) |

||

|

Belle Blanding and Dean Callander, CCG | ||

|

Craig Blackwell, Blackwell Boatworks (Manns Harbor, NC) Steve White, Brooklin Boat Yard (Brooklin, ME) |

||

|

Belle Blanding, CCG | ||

|

Jeff Wright, Gougeon Brothers Inc. (Bay City, MI) |

There were also two very interesting seminars on 3D printing:

|

Nathan Thompson and Kevin Houghton, Hodgdon Yachts (Damariscotta, ME) | ||

|

Kurt Jordan, Jordan Composites Inc. (Mill Valley, CA) Greg Lynn, Greg Lynn Form (Venice, CA) |

The first of these 3D printing seminars was presented by structural/design engineers at Hodgdon Yachts (well-known projects include MAKO and the all-carbon 100-ft sloop Comanche). It was a very educational rundown of how Hodgdon is using 3D printing, showcasing the types of unique parts and manufacturing solutions it enables in marine construction.

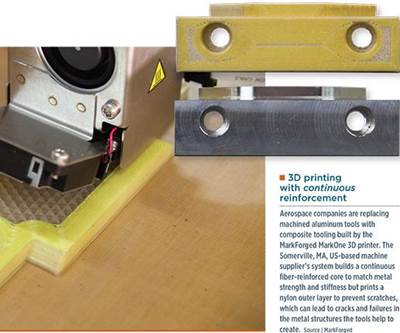

The second talk was given by Kurt Jordan, a well-known composites design engineer who has worked on multiple America’s Cup teams (including 2013 champion Oracle Team USA) and Greg Lynn, world renowned architect and pioneer in using digital design and carbon fiber composites in buildings and industrial design. Again, the theme was how 3D printing can be used to provide unique solutions in composites and boat construction. However, the side stories presented by both were equally absorbing. Jordan’s discussion of the engineering challenges in the AC 72 foiling catamarans and how the team has already used 3D printing to help explore solutions was extremely interesting. Lynn’s 42-ft carbon fiber trimaran Girlfriend, also pushed limits, including a 100% digital design completed before construction ever started (VERY rare in boatbuilding), a 23-kg (50-lb) interior fabricated before the hulls were completed and which dropped into the finished hulls perfectly, serving as both furniture and hull stiffeners, and 3D-printed fiber reinforced nylon steering quadrants and rudder arms with strength similar to CNC-cut aluminum billet but at 1/3rd the cost and zero milled material waste. All four parts weigh less than 4 kg (9 lb).

New Products

Even outside of the Future Materials exhibit, the IBEX exhibit floor showcased a variety of new products for composites.

3A COMPOSITES BALTEK INC. (High Point, NC) highlighted its higher density AIREX T92.320 polyethylene terephthalate (PET) foam core for boat transoms and other applications where it offers less weight vs. high-density polyurethane (PU) foam, for example 20 lb/ft3 (pcf) vs. 24-26 pcf for PU products. Representatives at the show said it is also a good product for through-bolting, easily drilled and tapped, with very high screw retention strength. AIREX T92.320 boasts higher properties vs. plywood and lower water absorption vs. PU foam, plus it is fully recyclable. Previously, the highest density product in the T92 lineup was 12 pcf. AIREX also has its US-based PET foam extruder coming online, which will be its third machine globally.

BIO BRANDS LLC (Cinnaminson, NJ) exhibited its BIO-SOLV, sustainable, bio-based solvent, which is 5 times stronger than petroleum-based solvents and lasts up to 10 times longer because it has such a low evaporation rate. It’s non-toxic so it presents less risk to workers and is made from environmentally-friendly ingredients, so no HAZMAT restrictions and handling costs. It also doesn’t require chemical, C02 or foam extinguishers like acetone, methyl ethyl ketone (MEK) and other solvents.

Composite Essential Materials displayed SAF 30 structural MMA adhesives and Class 1 ASTM E-84 fire retardant panels for structural applications. SOURCE: CW

COMPOSITE ESSENTIAL MATERIALS LLC (CEM, Port St. Lucie, FL) displayed new SAF 30 methyl methacrylate (MMA) structural adhesives from partner company, Arkema / AEC Polymers (Le Barp, France), touting their low exotherm — reportedly 100°F/40°C less than most MMAs — and also low shrinkage (<1%) during cure. SAF 30 products range from very flexible (400% elongation) to hyperstructural (30% elongation) and open times ranging from 5 to 90 minutes.

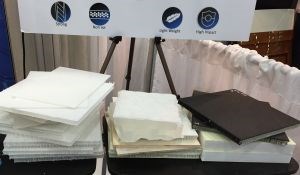

Composite Essential Materials has also successfully sold its lightweight, high-impact fire-resistant NIDAPLAST polypropylene honeycomb panels into the hotel building and construction industry. The panels have achieved a Class 1 ASTM E-84 fire-retardant rating, and have lowered installation costs due to their low weight while still meeting structural and fire requirements. An added value of the composite panels is their inability to rot, which helps to eliminating water intrusion and mold. The panels also provide sound deadening between stories in both floors and ceilings.

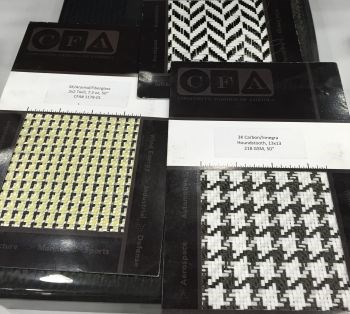

COMPOSITE FABRICS OF AMERICA (CFA, Taylorsville, NC) showed CW samples of new hybrid fabrics that not only offer toughness, but also truly unique aesthetics. The 2x2 twill at left features 3K carbon, aramid and E-glass fibers in a 7.3 oz (248 gsm) areal weight fabric while the 3K carbon fiber/Innegra S houndstooth at right is a 218 gsm fabric.

Mahogany Company’s prefabricated composite sandwich panels with carbon fiber and hybrid skins (left). Viking Yachts uses a variety of Mahogany composite panels, for example in the Viking 92 bulkheads (right), to reduce weight and boost performance.

SOURCE: CW (left) and Mahogany Company and Viking Yachts (right).

MAHOGANY COMPANY (Mays Landing, NJ) celebrates its 75th anniversary this year and highlighted its prefabricated sandwich panels made with a variety of skin materials, including carbon fiber, carbon fiber/E-glass hybrids and KEVLAR aramid fiber/E-glass hybrids. The panels can be cut to net-shape and kitted for boatbuilder use as doors, bulkheads, floors/soles and more. Panel skins most often feature quadraxial and biaxial noncrimp fabrics, but the company’s 4’ x 8’ and 5’ x 10’ presses are amenable to a wide range of materials, depending on customers’ needs for weight and labor savings. Renowned builder Viking Yachts (New Gretna, NJ) is using lightweight composite panels from Mahogany in all of its models to reduce weight and boost performance.

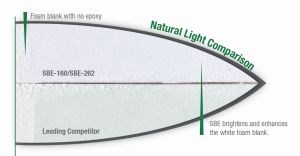

PRO-SET has launched its new Surfboard Epoxy (SBE) resin systems, formulated for high-volume production, excellent sandability and great UV and color stability for outstanding graphics. The company tested numerous formulations to ensure its final product range was the best possible to meet the needs and expectations of surfboard builders, including the whitest white, to brighten and enhance graphics.

UBIQUE (Clanton, AL) is not so much a new product as it is a new company, for me at least. Gurit has supplied materials into this manufacturer of prefabricated composite kits for some time.

Vectorply’s new pultruded carbon fiber rod-reinforced VectorUltra CF-LCX 3610 fabric offers high stiffness, low-weight and channels for resin infusion (center)

while its new skin coat fabric (right) saves time and weight. SOURCE: CW.

VECTORPLY publicized the new web-based version of its proprietary VectorLam laminate analysis program. VectorLam Cirrus 2.0 is cloud-based and multi-platform compatible, helping users to design composite laminates that best meet their stiffness, strength, weight and cost requirements.

Vectorply also highlighted two new products. The first, CR-LCX 3610, a combination of pultruded carbon rods and dry carbon tow VectorUltra fabric, has been designed for applications requiring increased compressive strength and stiffness from a vacuum-infused unidirectional. Typical vacuum infused carbon uni fabrics do not produce high in-plane, fiber-direction, compressive properties due to several factors including low fiber alignment which is inherent in the process. The pultruded carbon rods provide increased fiber alignment and compressive properties, and the combination of rods and dry carbon tow allow for easier handling compared to precured or fully pultruded carbon fiber materials.

The second, E-BXCFMPB, is part of the VectorFusion product line. It combines flow media, 2-mm thick core, knit reinforcement and additional veil layers into one product. Designed to aid resin flow during infusion, minimize print, reduce layup time and also the number of products a shop has to inventory and manage, it provides a total print blocker laminate solution in one fabric. Vectorply has made machine modifications to manufacture fabrics with up to 7 different material layers and thickness as high as 9.5mm. "Many of our customers want to move to infusion, but they don't want the cycle time to take longer than open molding," says Vectorply's composite engineering director Trevor Gundberg. "They also want the infused products to have cosmetics that are equal or better than their current open molded parts." He says that using VectorFusion Print Blocker can reduce layup time by over 50%, adding, "We nailed the cosmetics performance and with this product, cycle times are no longer a challenge."

Related Content

BiDebA project supports bio-based adhesives development for composites

Five European project partners are to engineer novel bio-based adhesives, derived from renewable resources, to facilitate composites debonding, circularity in transportation markets.

Read MorePro-Set named official materials supplier for New York Yacht Club American Magic

Competitive sailing team prepares for the 37th America’s Cup beginning in August 2024 with adhesives, resins and laminate testing services for its AC75 monohull construction.

Read MoreHenkel receives Airbus qualification for European aerospace manufacturing facility

The adhesive company’s Montornès, Spain, plant has been approved as a standard and raw materials supplier for various Airbus platforms, adding to its work in lightweighting, fuel efficiency and automation.

Read MorePittsburgh engineers receive $259K DARPA award for mussel-inspired underwater adhesion

The proposed META GLUE takes inspiration from hydrogels, liquid crystal elastomers and mussels’ natural bioadhesives to develop highly architected synthetic systems.

Read MoreRead Next

Additive manufacturing: Can you print a car?

Collaborative demonstration dispels doubt about 3D printing’s disruptive potential for direct-to-digital manufacturing of just about anything BIG.

Read More3D Printing: Niche or next step to manufacturing on demand?

With and without fiber reinforcement, additive manufacturing is making an impact, but to what end?

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More