Roth develops high-volume LPG tank line

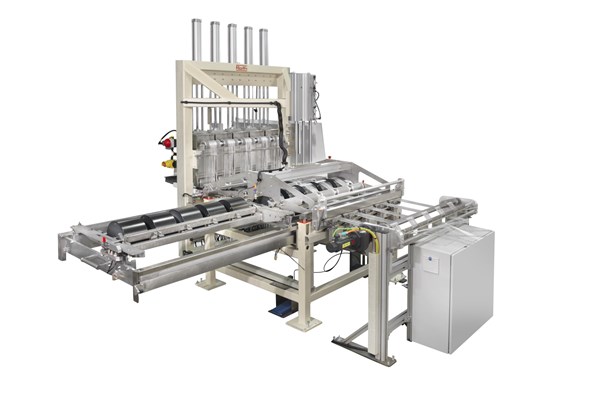

The gantry-based filament winding system is designed to produce as many as 600,000 plastic-lined, glass fiber-overwrapped liquefied petroleum (LPG) gas pressure vessels per year.

Share

The Roth production line is equipped with four assembly and handling robots for

efficient production processes.

Roth Composite Machinery (Steffenberg, Germany) has developed a fully automated production line for the manufacture of composite liquefied petroleum gas (LPG) vessels using filament winding. The line contains four winding stations — each with five spindles — and enables the manufacture of 600,000 plastic-lined, glass fiber-overwrapped LPG vessels per year. Cycle time, says the company, is 43 seconds per vessel.

The production line is based on the twin concept: Two independent winding stations are placed in one gantry. The loading and unloading of the vessels is done with robotics. Other features include a resin bath with shuttle table for the impregnation of the fibers, and a patented procedure for the automatic applying and cutting of the fibers being integrated in the fiber delivery carriage. Roth says the control system guarantees precise positioning of the fibers onto the vessel. The gantry design is said to provide high precision between the spindles and overall stiffness of the total system. The tolerance value of the composite material from spindle to spindle is <2g.

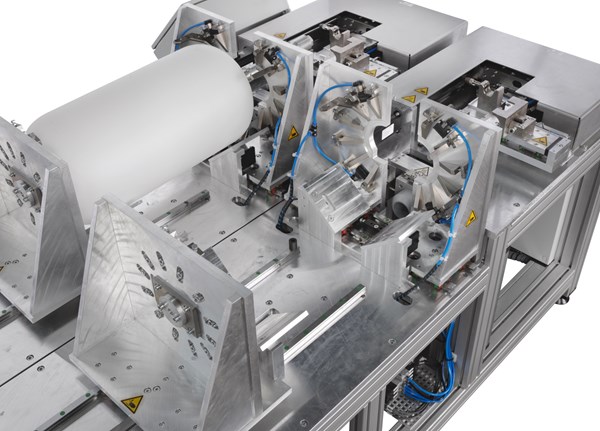

The impregnating bath with shuttle table. During service or cleaning cycles, says Roth, the production process can be continued.

Besides a blow-molding machine for the HDPE liners, the system includes a liner pre-assembly station where the boss part is welded onto the liner, the shaft is screwed in, the vessel is pressurized and the liner surface is activated for the winding process by means of flame treatment. Four handling and assembly robots allow precise and fast production processes. At every station, the identification number of each vessel, applied as QR codes, is read and stored. Thus, the process data for each product is traceable, for production and quality control.

Roth has been developing, planning and manufacturing filament winding machines for 50 years and has almost 30 years of experience in the development of fully automated machines in this sector. Roth has delivered more than 500 production lines globally.

Fully-automated welding machine for connecting the boss part with the HDPE liner.

“Having a cycle time of 43 seconds per vessel, it is the world’s most effective production line of this type at present,” claims Bernd Fischer, sales director at Roth Composite Machinery. “The advantages of fiber-reinforced plastics for LPG vessels are clear – they are significantly lighter than conventional materials and allow a realization of complex product geometries with highest stability.”

Related Content

-

Composites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

-

Hexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.

-

Update: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.