SAMPE 2011 Long Beach

SAMPE returns to Long Beach in partnership with aerospace industry materials society ASM International.

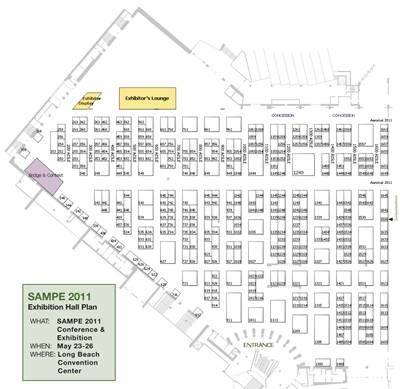

After successful events in the Pacific Northwest in 2010 and on the East Coast in 2009, the Society for the Advancement of Material and Process Engineering (SAMPE) brings its annual U.S. Conference and Exhibition home to Southern California this year. For the first time, SAMPE and ASM International, the society for aerospace materials engineers and designers, are colocating SAMPE 2011 and ASM’s AeroMat 2011 at the Long Beach Convention Center (Long Beach, Calif.).

The SAMPE conference features four days of technical education, beginning with a full day of tutorials (May 23) and three days of technical paper presentations (see “SAMPE 2011 at a Glance" by clicking on its title under "Editor's Picks," at top right). Among the highlights is a panel discussion that wraps up the day on Monday, titled “The Other 95%: Opportunities Outside Aerospace.” (A list of SAMPE 2011 exhibitors is posted on this Web site. Click on the appopriate title under "Editor's Picks.")

Moderators William Kreysler, president, Kreysler & Associates (American Canyon, Calif.), and Craig Riley, vice-president, Composites West LLC (Incline Village, Nev.), say the composites know-how amassed in the aerospace industry has been tapped, thus far, by less than 10 percent of the fabricators who power the annual $2 billion (USD) composites industry. Panelists will discuss how aerospace manufacturers and their materials suppliers can turn this lack of widespread expertise to their advantage by pursuing business opportunities in construction and architecture, where recent developments in building codes, material systems, design methods and environmental concerns have opened the door to composites.

The keynote presenter on Tuesday (May 24), Anthony Lawson, president of Gardena, Calif.-based HITCO Carbon Composites, will examine the upside and lessons learned during his company’s recent integration of automated composites manufacturing technologies.

Following a full day of technical paper sessions, conference attendees can network at SAMPE’s Welcome Reception, a free event open to all badged visitors, from 5:00 to 6:00 p.m. in room 104 at the convention center.

The following morning (May 25), keynoter Andreas Wüllner, managing director, SGL Automotive Carbon Fibers GmbH (Wiesbaden, Germany), will take a look at the 2009 SGL/BMW joint venture behind the BMW Megacity Vehicle project, which is expected to produce the four-passenger all-electric i3 commuter car, with many structural components made of carbon fiber-reinforced polymer, including its “life module” or passenger cell. The joint venture provides a dedicated supply of carbon fiber reinforcement for the project (manufactured at a new factory in Moses Lake, Wash.). Wüllner will review the challenges involved in opening a new carbon fiber manufacturing facility and discuss SGL’s vision of the large-scale use of carbon fiber-reinforced plastics in automotive applications.

In addition to the keynotes, SAMPE will offer three featured lectures, given concurrently, at 2:00 p.m. on Wednesday. Dave Inston, project leader, out-of-autoclave technologies at Airbus’ (Toulouse, France) U.K. facility, will discuss his company’s work to develop “‘Out-of-Autoclave’ Composites Curing Technology.” The technology uses several methods to defray the cost of energy consumption for the 90 percent of Airbus composite aircraft components that are now cured in autoclaves.

In “Carbon Composites e.V.: The Competence Network,” Klaus Drechsler, head of the Institute for Carbon Composites at TU München (Munich, Germany), will introduce listeners to Carbon Composites e.V. (CCeV), an association of German-speaking fiber-reinforced plastic processors and research institutions that fosters research in the aerospace, automotive, transportation, energy and mechanical-engineering arenas.

The third presentation is titled “Assessing and Managing Technical Risk in Transition of Technology into Systems.” Lecturer James J. Thompson, director, major program support in the Office of the Deputy Assistant Secretary of Defense (Systems Engineering) for the U.S. Department of Defense (DoD), will outline evolutionary changes to the DoD’s governance of technology transfer in large defense programs, made in an effort to improve what resulted previously in mixed or unintended results.

Bridge and wing building contests

For 13 years, SAMPE has hosted a competition for student members to design, analyze and build either a wing or a bridge for testing at the annual U.S. SAMPE Convention. Last year 69 teams from 18 universities and colleges participated in this competition.

The students engineer and fabricate test articles from either self-supplied materials or kits that SAMPE donors provide. At the SAMPE conference each year, the teams present their designs; they are weighed and then loaded to failure. The teams that have the best designs are recognized at the conference and are awarded prizes. Testing for the 14th annual contest will take place Wednesday, May 25, on the show floor.

AeroMat agenda

One day shorter than the SAMPE trade show, the AeroMat conference will run from May 23-25. Organizers expect technical experts from more than 200 companies in the aerospace materials supply chain to attend, including material suppliers to processors, airframe and engine designers, equipment manufacturers, university researchers and government end-users. Conference-goers will attend a plenary session on Monday afternoon (May 23) and will have the choice of technical paper sessions in eight general subject tracks, under the 2011 theme, “New Era in Flight: Design and Manufacturing of Advanced Materials for the Future.”

Of potential interest to HPC readers, papers presented as part of AeroMat’s Emerging Materials and Processes track, Session 4 (Wednesday, May 25, 1:30 p.m. to 5:30 p.m.), will explore “Polymers, Composites and Nanomaterials.” Additionally, Session 1 of the Model Development and Implementation/Validation track will cover “Modeling and Simulation of High-Temperature Materials” (Monday, May 23, 8:00 a.m. to 12:00 noon). Finally, Session 3 of the Welding and Joining Technologies and Methods track (Wednesday, May 25, 1:30 p.m. to 5:00 p.m.) will feature “Joining Technologies,” which will include mechanical-fastening and welding techniques used to join metals to composites. As an added bonus, SAMPE conference attendees can attend AeroMat 2011 conference programs at no additional charge.

The HPC staff, of course, will be on hand in Long Beach, in booth 1639. Look for our annual SAMPE show wrap-up in the July issue.

For more information about SAMPE 2011, contact Priscilla Heredia,Tel.: (626) 331-0616 x610; e-mail: priscilla@sampe.org.

For more information about AeroMat 2011, visit http://www.asminternational.org/content/Events/aeromat/.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

SAMPE 2011 Long Beach Exhibitor List

This SAMPE 2011 Exhibitor List is accompanied by a feature-article preview and a brief description of SAMPE show-related events, listed at top right under "Editor's Picks."

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)