SGL Group optimizes supply chain for composites

SGL’s takeover of former BENTELER and BMW JVs, plus sale of Kumpers JV, consolidates the company’s CF activities while it broadens its composites technology portfolio.

Share

Read Next

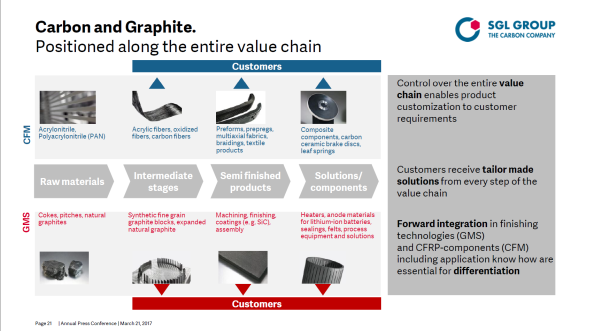

SGL Group (Wiesbaden, Germany) is a leading manufacturer worldwide of products and materials made from carbon focusing on the megatrends of mobility, energy and digitization. The company’s extensive product portfolio ranges from carbon and graphite products and carbon fiber to composite parts. Over the past two years it has made a series of organizational maneuvers as part of its strategic realignment :

- Sale of its Performance Products business unit (graphite electrodes business & cathodes, furnace linings and carbon electrodes business)

- Focus on two business units (Graphite Materials & Systems and Composites – Fibers & Materials) to drive future growth

- Takeover of BENTELER-SGL joint venture from BENTELER Automotive.

- Takeover of SGL Automotive Carbon Fibers (SGL ACF) from BMW.

- Sale of shares in SGL Kümpers joint venture.

Throughout, SGL has communicated that its mission is to concentrate its expertise in the processing of carbon and glass fibers for composites materials and components into a single Composites – Fibers & Materials (CFM) business unit.

One of its first steps to establish this complete supply chain was construction of a new 200,000-m2 polyacrylonitrile (PAN) precursor production plant in Lavradio, Portugal. “We now have the complete value chain of high-quality carbon fiber materials available in-house to further support our customers,” said the plant’s managing director Stefan Seibel. The plant will feed SGL’s Sigrafil carbon fiber production facilities at Muir of Ord, Scotland and Moses Lake, WA, US.

Composite parts, carbon fiber and textiles

SGL’s next action was to secure the other end of the chain through its joint venture with BENTELER Automotive in Ried and Ort im Innkreis, Austria. “The complete takeover of BENTELER-SGL enables us to expand our serial production capabilities for components made from fiber-reinforced composites,” explains SGL Group CEO Jürgen Köhler. “In the future, we will be able to offer our customers one-stop-shop solutions along all steps of the value chain, from carbon fibers to materials and components. This serial production expertise will also be made available to other industries.”

“We will continue our successful partnership with SGL Group in the future to purchase products made of glass or carbon fiber reinforced plastic, where necessary," said BENTELER Automotive CEO Laurent Favre.

The next action was SGL’s acquisition of BMW’s stake in SGL Automotive Carbon Fibers (SGL ACF), which will be completed in two steps:

- Wackersdorf, Germany transferred in January 2018.

- Moses Lake, WA, US transferred year-end 2020.

SGL ACF’s existing supply agreements with BMW for the BMW i3, BMW i8 and BMW 7 series that span into the next decade will remain unchanged. SGL Group has also entered into an agreement with BMW Group to continue working together on future projects involving the use of carbon fiber.

Finally, SGL has divested its shares in the joint venture with Kümpers GmbH (Rheine, Germany). Here also, it will continue to supply fiber, which Kümpers uses in selected products within its array of woven and nonwoven technical textiles, including braids.

Composite development continues

Meanwhile, SGL will advance its activities in the 2016-launched Lightweight Applications Center (LAC, Meitingen, Germany). Here, it is working with a broad range of customers to develop innovative solutions using its expanding range of technologies. One example is the Carbon Carrier structural composites concept for electric vehicle interiors. Developed with industrial design firm Bertrandt (Möglingen, Germany), the Carbon Carrier integrates all major function and trim components of a conventional instrument panel while imparting a more open, light and floating aesthetic. “While designing the Carbon Carrier, we made sure that the components, technologies and assembly concepts used were ready for large-scale production, either now or in the near future,” says Michael Hage, Head of Body Development/CAE at Bertrandt. “For electric vehicles in particular, reduced weight means a greater range."

Through the LAC, SGL customers can access its complete range of engineering services — from initial conceptualization and computer aided structural design, to analysis, optimization and prototyping through to industrialized serial production — with the ability to develop tailored material and process solutions.

It has also announced the launch of new thermoplastic products including long fiber thermoplastics (LFTs), unidirectional (UD) tapes and organosheets in polyamide (PA), as well as new developments in carbon fiber sized for polypropylene composites, thermoplastic profiles and carbon/glass hybrids for automotive and other high-volume applications.

“We want to support the break-through of composites in large-scale production,” declares Andreas Wüllner, chairman of the CFM business unit.

Related Content

Bio-based, fire-resistant composites become mainstream

Projects use Duplicor prepreg panels with highest Euroclass B fire performance without fire retardants for reduced weight, CO2 footprint in sustainable yet affordable roofs, high-rise façades and modular housing.

Read MoreSustainable Infrastructure Systems creates fiber-reinforced post-consumer plastic structural panels

Australian composites manufacturer offers a scalable building solution, already established in a pedestrian bridge application, to tackle unprocessed soft plastics waste.

Read MoreComposites end markets: Infrastructure and construction (2024)

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

Read MoreGatorbar, NEG, ExxonMobil join forces for composite rebar

ExxonMobil’s Materia Proxima polyolefin thermoset resin systems and glass fiber from NEG-US is used to produce GatorBar, an industry-leading, glass fiber-reinforced composite rebar (GFRP).

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More