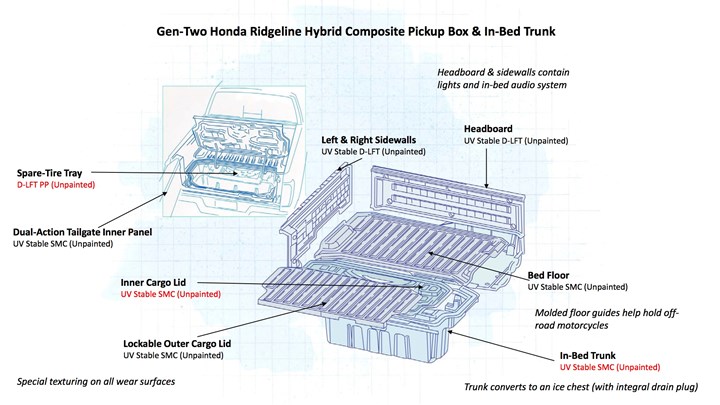

SMC + D-LFT: A hybrid box for the Gen 2 Ridgeline

D-LFT optimizes vertical component functionality while first use of weatherable SMC eliminates paint, reduces mass and stands up to tough-duty use.

Although it wasn’t the first pickup with a composite box, when the all-wheel-drive Honda Ridgeline from American Honda Motor Co. Inc. (Torrance, CA, US) launched in spring 2005, it attracted significant attention for its abundance of clever features. It included a unique, lockable, weathertight in-bed storage trunk with a drain plug that doubles as a giant ice chest/cooler, plus a spare-tire tray forward of the trunk, a dual-action tailgate, integral tie-down cleats and in-bed lights, and bed floor guides to accommodate multiple off-road motorcycles. And it had high load-carrying capacity (up to 1,100 lb/499 kg). Further, its sheet-molding compound (SMC) composite box was 30% lighter than a comparable steel design and, thanks to the significant parts consolidation opportunity composites offer, part count was reduced from what would have been more than 100 in steel to a mere seven — which ultimately enhanced manufacturability, assembly and in-service durability, and would have been impossible or impractical in metals.

Honda’s first foray into pickups so impressed judges that it won more than a dozen industry awards, including the prestigious 2006 North American Truck of the Year. Additionally, it was the first four-door/crew-cab pickup to earn five-star safety ratings from the US National Highway Traffic Safety Admin. (NHTSA), and it was the Insurance Institute for Highway Safety’s (IIHS) Top Safety Pick in the pickup category in 2009, 2012 and 2013.

With all this going for it, it’s no surprise that the first-generation Ridgeline developed a loyal customer base during its lifecycle between the 2006-2014 model years. When it was time to do a refresh for generation two, the pressure was on to create what Honda R&D Americas Inc. (Raymond, OH, US) calls “a worthy successor.”

Gen 2: Design flexibility the key

“Our first-generation Ridgeline broke new ground in terms of having in-bed storage, which we achieved using the design flexibility that composite materials afford,” explains James Ryan, principal engineer, materials research division, Honda R&D. Many of the system-usage targets for strength, durability and manufacturability on the Gen 2 composite truck box were built on the know-how gained from the first system. “We began by asking ourselves, ‘How can we improve or add additional value for our customers?’” adds Ryan, who notes that everything from the shape of the bed’s corrugations, and thickness of individual sections to the texture placed on wear surfaces and the material formulation, was examined and optimized to achieve the best performance for the customer.

Not the first, just the best. Although it wasn’t the first pickup with a composite box, when the Honda Ridgeline from American Honda Motor Co. Inc. (Torrance, CA, US) launched in spring 2005, it earned a collection of honors, in part, for its composite pickup bed, featuring an in-bed storage trunk (with drain plug) that doubles as an ice chest/cooler, integral spare-tire tray behind the storage trunk, a dual-action tailgate, integral tie-down cleats and in-bed lights, and a high load-carrying capacity. When it was time to do a Gen 2 refresh, the pressure was on to create what Honda R&D Americas, Inc. (Raymond, OH) calls “a worthy successor,” pictured here. Source (all photos) | Honda North America Inc.

The design team looked at many materials — polymeric and metallic — during preliminary design work for the first- and second-generation models. Choosing composites-intensive designs for both generations of Ridgeline pickup boxes was not without risks or challenges. “We already knew from our previous Ridgeline that the robustness that composites offered made them perfect for maximizing customer value,” recalls Ryan. This approach follows Honda’s philosophy of using the right material in the right place and incrementally improving it in terms of performance, quality and value to “maximize customer joy,” he says.

“One thing about composites vs. steel and, in some cases, aluminum, is that these materials are younger in terms of total usage in the automotive industry,” says Ryan. “A big challenge that we face, industry wide, is the need to educate people — from design to testing to manufacturing — about these materials and help them gain experience using them. Another aspect, and one that’s extremely important at Honda, is our need to guarantee overall quality, safety and robustness for our customers. To do that, we need to accurately predict performance up front and know we’ll achieve good correlation with physical testing. It’s vital to have reliable predictive capabilities for all the materials we use, and that’s another issue we still face with composites.”

From mono- to multi-material system

The Gen 1 design was essentially a painted, structural SMC system with bonded metal stiffeners and molded-in mounting collars produced by Continental Structural Plastics (CSP, Auburn Hills, MI, US). To add features and reduce mass and costs for Gen 2, the team went with a multi-material system. While all load-bearing surfaces in the bed, trunk and liftgate inner remained in SMC with stiffeners and mounting collars, this time, the box’s sidewalls and headboard were compression molded from molded-in-color (MIC) black, fiberglass-reinforced, direct-long-fiber thermoplastic (D-LFT) with a polypropylene (PP) matrix. The spare-tire tray was injection molded from short-glass PP.

“With any material, you have plusses and minuses,” explains Ryan. “No single material is always right for every application across the board.” Although researchers declined to provide details on the specific decision matrix used to specify the D-LFT and injection-PP formulations, team members did say that materials selection was driven by differences between the performance criteria for the box’s vertically and horizontally oriented parts. The formulation was optimized jointly by Honda, CSP, and additive supplier Addcomp (Rochester Hills, MI, US).

Mold-in-color D-LFT + unpainted SMC. To add features and reduce mass and costs for the Gen 2 pickup box, the team went with a multi-material system. Load-bearing surfaces (bed, trunk and liftgate) remained in SMC, but the box’s sidewalls and headboard were compression molded from molded-in-color (MIC) black, fiberglass-reinforced direct-long-fiber thermoplastic (D-LFT) with a polypropylene matrix. The carryover SMC parts were incorporated without the need for paint, thanks to unique formulation work by suppliers that enabled the use of a new weatherable structural grade of fiberglass-reinforced UP-SMC in the Gen 2 box

Even the carryover SMC parts went through considerable scrutiny to see how much more value could be added. One area that was identified was paint elimination. Although SMC is known for its toughness, stiffness, chemical resistance, weight reduction, low scrap, design flexibility and relatively fast compression molding cycle times (2-3 minutes, button-to-button, even for large parts), it is not considered weatherable in typical vinyl ester or unsaturated polyester (UP) formulations. For that reason, it is generally painted for applications that will involve outdoor exposure. However, paint adds cost and environmental burdens that Honda wished to avoid.

Thanks to unique formulation work by resin supplier Ashland LLC (Dublin, OH, US) and additive supplier Chromaflo Technologies LLC (Ashtabula, OH, US), all the Gen 2 Ridgeline’s visible SMC box components use a new weatherable (UV-stable) structural grade of fiberglass-reinforced UP SMC (specific gravity = 1.8). The MIC black material was compounded and molded by CSP, which also has produced SMC pickup boxes for Ford Motor Co. (Dearborn, MI, US) and Toyota Motor Corp. (Toyota City, Aichi, Japan).

“Ashland has been doing development work on weatherable SMCs since the 1990s,” notes Dan Dowdall, Ashland global business development manager – transportation composites. “Honda and CSP had interest in a weatherable grade for the Gen 2 Ridgeline to improve the bed’s durability and scratch resistance, but had very demanding requirements for color stability, gloss retention and mechanical properties. After extensive trials and testing, the Ashland-CSP SMC 834UV formulation was approved for use.” He says this application represents the first commercial use of the material in any industry.

Texturing of SMC wear surfaces was another area of focus to increase damage resistance and hide minor scratches. Previous research by Ashland showed that using different textures on SMC parts produced via identical formulation and molding conditions caused them to weather differently. That work, plus further input from CSP, the texture house and the toolmaker was used by Honda to select the final texture family, grain type and grain depth. Combined, the weatherable formulation, MIC pigmentation and texturing eliminated the need for paint without sacrificing mechanical or chemical performance vs. the Gen 1 model. Furthermore, it enhances user experiences by keeping the bed looking great longer — particularly for those who haul heavy loads and/or abrasive materials.

Additional work was done to ensure the SMC and D-LFT materials looked good side by side. “Given that we planned to use an unpainted, multi-composite system for all show surfaces, our team spent considerable time and effort focused on appearance and marketability criteria, including the as-molded appearance, color matching the SMC and D-LFT materials — considering not just base color over time and UV exposure, but also orientation, gloss and texture effects — and overall usability,” notes Ryan.

Increasing customer joy

Other Gen 1 design and construction details were optimized to improve overall manufacturability and assembly and to optimize vehicle mass and performance. A notable addition is the smartphone-controllable, in-bed audio system, which features six weatherproof audio “exciters” (transducers) — two in each box’s sidewall and two in the box’s headboard. These transmit vibration from the truck’s audio system and turn bed walls into resonant speakers — another industry first. That and the Gen 2’s slightly smaller in-bed trunk/cooler, make the new Ridgeline, according to Honda, the “ultimate tailgate-party vehicle.”

“Our end goal is delivering a product that exceeds customer expectations and maximizes the joy they experience from utilizing our products,” adds Ryan. “We took great care to keep such considerations in mind throughout development.”

Lighter, faster but just as tough. The Ridgeline’s new weatherable SMC not only was reduced in density and saved the painting step during manufacturing, but did so without sacrificing the pickup box’s chemical or — as this photo makes clear — mechanical performance, particularly for users hauling heavy loads and/or abrasive materials.

The Gen 2 Ridgeline pickup made its debut in May 2016. Said to offer better hauling and towing performance than its predecessor and be the market’s smoothest and quietest midsize truck, it offers greater interior volume (depending on trim level) and a wider, longer, more durable bed that is stronger than competitors’ beds with similar payload capacity (see photo above). And for the first time, a front-wheel-drive version is available in North America.

What’s next for the Ridgeline? “Lots of people are speculating about where the industry is going and how customers will use cars in 10 to 15 years,” Ryan answers. “To keep maximizing value, we must keep finding the customer’s value proposition.”

Will composites continue to play an important role? “We need to look at where composites can enable quality, safety and robustness,” he adds. “You can find clues as to where we’re heading by looking at the products we’ve already launched. Hopefully we’ll be able to continue to grow these applications by finding the right fit.”

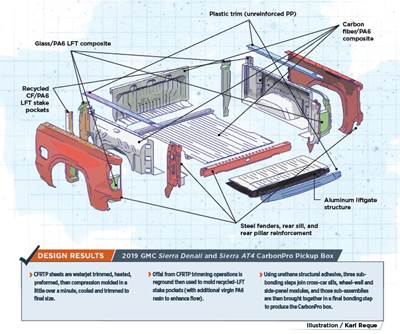

For more on composite pickup boxes, see CW’s coverage of General Motors Co.’s carbon fiber-reinforced thermoplastic composite CarbonPro, which debuted on select 2019 pickups.

Related Content

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreCompPair adds swift prepreg line to HealTech Standard product family

The HealTech Standard product family from CompPair has been expanded with the addition of CS02, a swift prepreg line.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreRead Next

Chopped carbon fiber, polyamide and innovation redefine the modern pickup truck bed

CarbonPro, the first thermoplastic composite box, boosts damage resistance, reduces mass 28 kg, scales to high production volumes.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;width=70;height=70;mode=crop)