SPE ACCE 2013 Review

The SPE’s annual Automotive Composites Conference & Exhibition gets a bigger venue, an expanded program and its best attendance ever.

At its new venue, the Suburban Collection Showplace and the adjoining Hyatt Place Hotel in Novi, Mich., the Society of Plastics Engineers’ (SPE) Automotive Composites Conference & Exhibition (ACCE) hosted nearly 900 attendees and featured a strong four-track program of papers and a crowded exhibit hall.

As always, presenters provided a wealth of information on innovations in materials and part design, as well as much improved and — particularly important at this juncture — faster molding processes, citing notable examples of successful composite applications in production autos. Many of the innovations have sprung from Europe, where automakers are scrambling to reduce vehicle weight and avoid strict financial penalties for failing to meet vehicle emission targets. And, despite one presenter’s statement that “the BMW i3/i8 program is equivalent to the Boeing 787 Dreamliner program for automotive composites,” some OEM representatives expressed doubts about full-scale adoption of composite materials.

That said, SPE ACCE cochair Antony Dodworth (Dodworth Design Ltd., Buckingham, U.K.) presented the award for Best Paper to one of several companies that might offer a significant piece of the composites-adoption puzzle; e-Xstream engineering SA (Louvain-la-Neuve, Belgium) took top honors for its discussion of virtual prototyping. The company’s CEO, Roger Assaker, spoke on “Multi-Scale Modeling of Failure of Continuous Carbon Fiber Composites Applications to Coupon Tests,” noting that e-Xstream is experimentally validating its DIGIMAT software for virtual testing of continuous fiber-reinforced composites and refining the calculations to more closely match test data. He pointed out that if composites are to successfully move into the body-in-white and other structural parts, software that already permits reliable progressive failure analysis of short-fiber-reinforced parts must be adapted and refined to accurately predict the behavior of continuous-fiber components.

That sentiment was echoed by R. Byron Pipes, the John L. Bray Distinguished Professor of Engineering at Purdue University (Lafayette, Ind.), who presented a new vision for moving engineers from a metals-centric and empirically based focus on isotropic material properties to a radical new paradigm in which engineers are aggressively introduced to the nonisotropic nature of composites. His vision includes the imperative that virtual simulation supplant physical testing to the extent that validation and certification processes focus on the computer-based software tools, rather than physical parts. “Computing power is 10 billion times better than it was in 1970,” says Pipes. “In 1970, what took years via computer takes minutes today. Simulation is one of the most important tools we have.” To that end, Pipes introduced the Composite Design and Manufacturing Hub, a central Internet meeting place for composites-based simulation education (www.cdmhub.org). The Hub will initially be enterprise-based, and software developers will offer “learning versions” of their simulation packages to site visitors. Individuals will eventually pay a small fee to access the site.

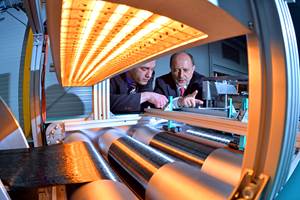

Elsewhere, new molding technology from Schuler SMG GmbH & Co. (Waghäusel, Germany) was presented by Patric Winterhalter, who discussed vacuum-assisted, high-pressure resin transfer molding (RTM) for carbon fiber car elements. Schuler is working with BMW on molding the BMW i3 Life Module (a carbon fiber composite passenger cell), among other parts. He emphasized that parallelism of the hydraulic press movement is critical, with counteracting cylinders used to account for potential off-center resin flow. The press design also must maintain an exact position, even with the forces produced by the injected resin. With Schuler’s technology, a three-minute cycle is almost within reach, claims Winterhalter.

Mitsubishi Chemical Carbon Fiber & Composites Inc. (Tokyo, Japan) Takeshi Ishikawa described a slit carbon fiber/thermoplastic “stampable” sheet with “flowability” and high mechanical properties that can be quickly molded at relatively low pressure to create highly complex parts, including vertical ribs. In fact, an entire program track was devoted to automotive carbon composites, with many speakers opining that “strong” demand for carbon fiber in autos will accelerate after 2015. Jan Anders-Månson (École Polytechnique Fédérale de Lausanne, Lausanne, Switzerland) explored some of the reasons why composites have not yet been widely adopted in automotive applications. He believes that recycling is a huge issue that needs more attention, and he advocated replacing virgin carbon fibers with recycled carbon fibers as a means to close the materials cost gap with steel.

A standout paper was presented by Marcie Kurcz, North America business manager for resin maker Polyscope Polymers (Geleen, The Netherlands). She described the design and manufacture of the semiconvertible sunroof frame for the Citroën DS3 Cabrio model, designed by Webasto (Munich, Germany) and molded by Shaper (La Séguinière, France) using a modified glass fiber-reinforced styrene maleic anhydride (SMA) resin from Polyscope. The composite part offers significant cost savings over other materials, enables part integration (seven parts were combined into one) and secured a 40 percent weight reduction compared to trial parts made from other considered materials. The glass/SMA part, she said, offers a viable “value proposition” that clearly favors the selection of composites.

In another session, there was considerable audience interest in a newly introduced process offered by Dale Brosius, president of Quickstep Composites LLC (Dayton, Ohio), the U.S. subsidiary of Australia-based Quickstep Holdings Ltd. (Bankstown Airport, New South Wales). Called Resin Spray Transfer (RST), this fast-cycle method takes an unusual approach. The structural resin is robotically sprayed directly onto the mold surface, and a fiber preform is placed over it. The resin, then, needs to flow only in the z-direction to wet out the reinforcement, which reportedly makes it possible to consistently produce a Class A finish. The impregnated preform is then cured in a Quickstep hot fluid machine. According to Brosius, a cycle time of 10 minutes is possible.

Several papers and keynotes discussed new and ongoing industry collaborations aimed at increasing the use of composites on high-production vehicles. Greg Rucks of the Rocky Mountain Institute (RMI, Snowmass, Colo.), an automotive think tank that Rucks called a “think and do tank,” believes that the successful introduction of a few specific parts on four mainstream vehicle models could double the global carbon fiber demand. His group’s “launch pad” aims to identify such parts, which might include a rear hatch inner, a door inner, an engine cradle and/or a seat structure made with large-tow carbon fiber and no cosmetic finish. Rucks notes that the effort offers a very viable value proposition: “Even though steel is less expensive, the three-year fuel savings for vehicle fleets made with the lighter carbon parts would offset the entire carbon fiber cost premium.” The RMI is putting together a supply chain team to create an innovation hub that will enable production of selected parts by 2018. RMI also noted that it is looking for an automotive OEM partner.

This year, for the first time, the industry discussion panel included two representatives from the aluminum industry: Doug Richman of Kaiser Aluminum (Bingham Farms, Mich.) and Mario Greco of Alcoa (Pittsburgh, Pa.). A point repeatedly raised by the panel members was that widespread use of structural composites in the auto industry is possible, and attractive, but adoption repeatedly stalls when the industry tries to make a business case because composite material costs are still high and processing speeds and part quality are still evolving. Several panel members said problems that center around attachments and fastening simply aren’t solved yet. Panelists also noted that the lack of predictive analysis software, training and education still hampers the industry’s familiarity with composites. Most panelists agreed that lifecycle analysis (LCA) is becoming more important to both OEMs and consumers, and that LCA analyses show that carbon fiber does not yet fare as well as aluminum, which enjoys a global recycling push. But panelist and keynoter Jai Venkatesan of Dow Chemical Co. (Midland, Mich.) pointed out that over time, the value of composites per unit cost has grown, because they vastly improve fuel efficiency and enable parts integration. He asserted that in reality, molding process speed has accelerated significantly in the past two decades so processing isn’t the roadblock anymore. The problem remains raw material cost. But Venkatesan believes lessons can be transferred from aerospace to automotive in order to drive “disruptive innovation.”

Related Content

Women in the Composites Industry brings together women for networking, educational opportunities

Aiming to support the growth of women in this industry, the WCI industry group and its partners recently held its first live training event hosted by Owens Corning.

Read MoreThe Native Lab launches composites course training membership plan

Courses that touch on the fundamentals of composite materials, design, analysis and more are available for individuals and companies alike through TNL’s online platform.

Read MoreBelzona opens fifth European SuperWrap Training Centre

Global training facilities provide intensive, first-class installer and supervisor training for proper use and application of Belzona composite pipe and tank repair systems.

Read MoreChemnitz University of Technology receives €6 million to expand research into "green" carbon fiber

Carbon LabFactory and InnoCarbEnergy project conduct R&D across entire value chain from raw materials through processes to structures and systems on a pilot line with technology demonstrators.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More