Dan Adams President

Dr. Daniel O. Adams is president of Wyoming Test Fixtures Inc. (Salt Lake City, Utah, U.S.) and an emeritus professor of mechanical engineering at the University of Utah, where for 23 years he directed the Composite Mechanics Laboratory. He holds a B.S. in mechanical engineering and an M.S. and Ph.D. in engineering mechanics. Adams has a combined 44 years of academic/industry experience in the composite materials fi eld. He has published more than 120 technical papers, is chair of ASTM Committee D30 on Composite Materials and co-chair of the Testing Working Group for the Composite Materials Handbook (CMH-17). He regularly provides testing seminars and consulting services to the composites

industry.

Crashworthiness testing of composites: A building block approach, Part 2

Following the previously discussed coupon-level testing element, subcomponent and component testing are the next steps in designing crashworthy composite structures.

Read MoreCrashworthiness testing of composites: A building block approach, Part 1

Determining the crashworthiness of composite structures requires several levels of testing and analysis, starting with coupon-level crush testing.

Read MoreTesting to support composite bolted joint analysis

An overview of ASTM Standard Guide D8509, and its coupon-level mechanical testing of design properties for analyzing composite bolted joints.

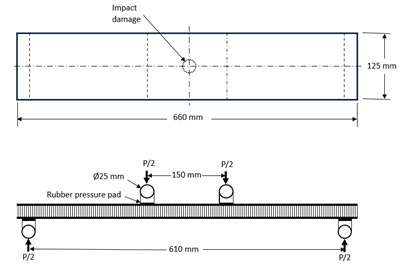

Read MoreDamage tolerance testing of sandwich composites: The sandwich flexure-after-impact (FAI) test

A second new ASTM-standardized test method assesses the damage tolerance of sandwich composites under flexural loading.

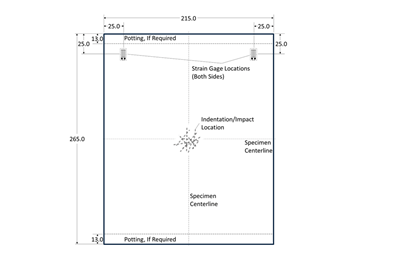

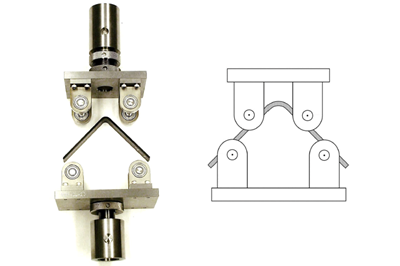

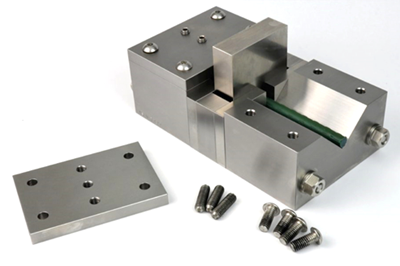

Read MoreDamage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

Read MoreInterlaminar tensile testing of composites: An update

New test method developments for measuring interlaminar tensile strength address difficulties associated with the ASTM D6415 curved beam flexure and ASTM D7291 flatwise tensile tests.

Read MoreComposite test methods (and specifications) for fiber-reinforced concrete structures

While initially focused on transitioning existing standards published by the American Concrete Institute, the relatively new ASTM Subcommittee D30.10 is developing new standardized test methods and material specifications for FRP composites.

Read MoreNotched testing of sandwich composites: The sandwich open-hole flexure test

A second new test method has been standardized by ASTM for determining notch sensitivity of sandwich composites.

Read MoreNotched testing of sandwich composites: The sandwich open-hole compression test

A new ASTM-standardized open-hole compression test method seeks to determine the notch sensitivity of sandwich composites.

Read MoreMaterial equivalence testing in shared composites databases

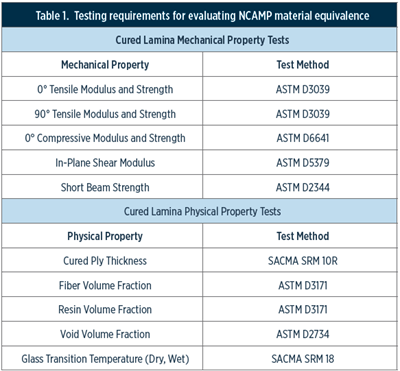

In response to traditionally proprietary polymer matrix composites (PMC) qualifications, NCAMP continues its efforts to make material property databases publicly available.

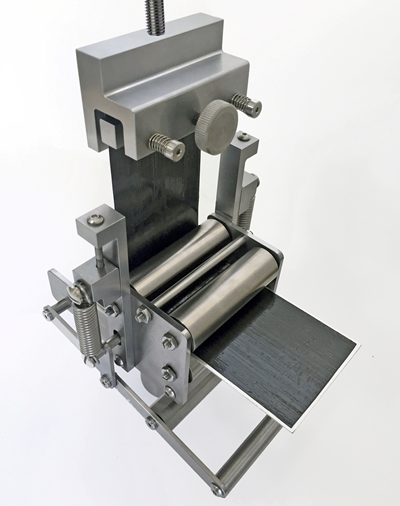

Read MoreComposite prepreg tack testing

A recently standardized prepreg tack test method has been developed for use in material selection, quality control and adjusting cure process parameters for automated layup processes.

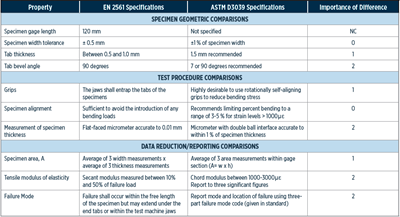

Read MoreDetermining the equivalency of composite test methods

While time consuming and somewhat subjective, the comparative assessment approach has been proven effective toward assessing composites test method equivalence.

Read More