Thermoplastic primary aerostructures take another step forward

Employing new manufacturing techniques and the design freedom they create, GKN Fokker has joined forces with Gulfstream to assess thermoplastic composites for primary aircraft structures.

Advantageous features of thermoplastic composites, such as toughness, comparatively high out-of-plane strength and sustainability/recyclability, have attracted aircraft design engineers to the notion of thermoplastic composite primary structures for decades. But aircraft manufacturing engineers have been uncertain about finding a cost-effective way to advance them from CAD simulation to the production floor. They are not, however, deterred: Efforts to develop the necessary manufacturing technologies have continued across the globe — perhaps nowhere as tenaciously as in the Netherlands.

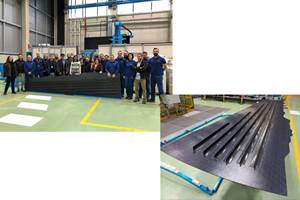

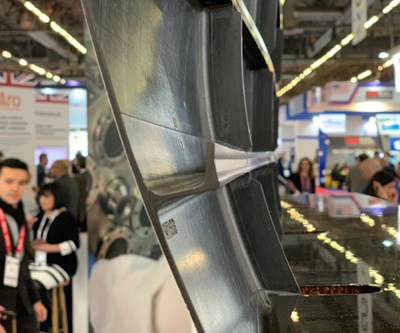

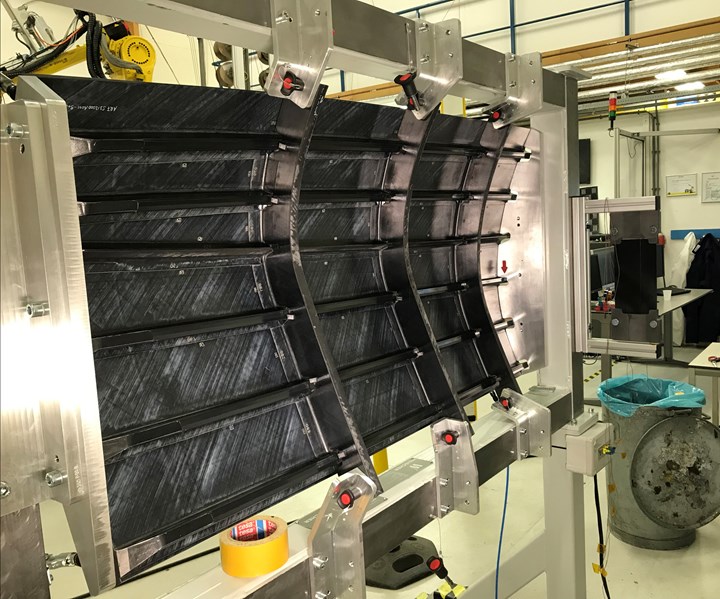

Integral L-stringers. The GKN Fokker carbon fiber/PEKK fuselage, designed and built for Gulfstream, incorporates curved longitudinal L-stringers with a slightly obtuse angle to enable tool release. CW photo | Jeff Sloan

In 2009, nine Dutch industrial companies and research institutes, together with Airbus (Toulouse, France), formed the Thermoplastic Affordable Primary Aircraft Structure (TAPAS) Consortium. The initiative expanded to 12 partners in 2014 and continued as TAPAS2. Targeting Airbus-developed applications under TAPAS2, GKN Fokker (Hoogeveen, Netherlands) recently developed a fuselage demonstrator using what it calls a “butt-jointed orthogrid technology” that enables cost-effective production of a thermoplastic composite fuselage design.

The full payoff of a thermoplastic composite primary aircraft structure — though still years away — may now be within sight as Gulfstream Aerospace (Savannah, Ga., U.S.) has partnered with GKN Fokker to advance its TAPAS2 fuselage technology, pointing the way toward possibly applying the materials and process to a full fuselage. The story behind the newly developed fuselage panel (which was displayed at JEC World earlier this year) is one of advancements in design and manufacturing methods, and further, in a more thoroughly integrated design-manufacture engineering approach.

“Traditionally,” explains GKN Fokker chief engineer Andries Buitenhuis, “whether they were using fabrics or unidirectional tapes, designers mostly stuck to conventional layers of 0-, 90- and 45-degree orientations. They would work from their ply layup tables, independent of other disciplines.” The new approach is an integrated, digitalized design-manufacture software platform (developed through TAPAS) in which engineers from various disciplines are all looking at the same digital model and have the ability to conceptualize more complex part designs. “This opens up a whole new world of unprecedented optimization possibilities,” Buitenhuis continues. “On complex shapes, fiber directions may be all over the place. We can build unconventional laminates and take a fresh look at design allowables, manufacturing gaps and overlaps, radiuses…. And you can optimize the structure’s strength locally.” These expanded design options more fully employ the fiber steering capability of automated fiber placement (AFP) machines, and advances in other manufacturing capabilities discussed below.

The design freedom afforded by this integrated digital system has proven indispensable to the design and manufacture of business jet panels. In the TAPAS2 fuselage designs, the carbon fiber/polyetherketoneketone (PEKK) panel (made with Solvay’s APC PEKK-FC) features a welded, fastener-free frame-to-skin joint, which is an essential contributor to the design’s cost-effectiveness. “We predict achieving cost parity with aluminum fuselage shells,” explains Arnt Offringa, head of thermoplastic composites technology at GKN Fokker, “and this is because aluminum shells are riveted.” The elimination of mechanical fasteners is expected to generate a 20% cost reduction and a 10% weight reduction in aircraft primary structures as compared to conventional composite solutions. Of course, much of the cost and weight savings come from the elimination of the fasteners themselves, as well as labor costs for installing them. Also of great importance is the elimination of holes in the composite components to accommodate the fasteners — holes that require added reinforcement and therefore added weight.

GKN Fokker reached technology readiness level (TRL) 3 (proof of concept) with Airbus for a pressurized fuselage, demonstrating cost parity with aluminum fuselage panels, under TAPAS2 in December 2017. Along the way, the GKN Fokker team expanded its vision for this thermoplastic fuselage technology from commercial airliners to business jet applications.

Gulfstream’s interest

GKN Fokker’s history of successful work for Gulfstream on thermoplastic composite components made a partnership with the business jet manufacturer a logical next step. “It is widely known that Gulfstream has been flying thermoplastic composite parts for years,” says Mark Chapman, manager of Gulfstream’s Advanced Structures and Materials Initiative (ASMI). He adds that the fuselage panel project “is a natural progression from what we’ve been doing, starting with simpler parts and moving toward primary structural parts.” GKN Fokker has partnered with Gulfstream in the development of numerous thermoplastic composite secondary components, including tail elevators and rudders as well as floor panels on the G650.

In 2015, Offringa and Buitenhuis presented TAPAS2 project developments to Gulfstream, and Chapman and his team recognized the potential for garnering the benefits of TAPAS2 results. “We saw the potential weight reduction benefits, better impact resistance and toughness, and enhanced performance,” Chapman recalls. Fastener-free design is also appealing. “Welding technology would enable us to assemble the fuselage more efficiently” than a mechanically fastened assembly, Chapman says.

The partnership with GKN Fokker supports Gulfstream’s research and development of more complex fuselage shapes that may not be economically feasible to produce with metal structures. “You can only stretch-form metal so far,” Chapman notes. “The splices and supporting structure necessary for complex shapes are not very efficient.” Offringa agrees: “Such complex geometries are difficult to manufacture with conventional technologies.”

Joining design and manufacture

To achieve a fastener-free, producible design, GKN Fokker’s approach focuses on withstanding the two key forces to which the fuselage joints are subject: cabin pressure and impacts such as tool drops. Cabin pressure places radial force on the fuselage, creating high loads in the frame-to-skin joint. In conventional designs, fuselage frames include “mouse holes” through which the longitudinal stringers pass. Under the force of cabin pressure, these mouse holes serve as discontinuities that are subject to high peel forces — a major concern for a fastener-free design, given composites’ low out-of-plane strength compared to metals. Impacts also generate high loads in the frame-to-skin joint because the frame does not flex under impact.

Double curvature. The thermoplastic composite fuselage panel accommodates the complex geometry of a Gulfstream business jet aft fuselage with fiber-steered AFP layup of the skin and co-consolidation of the orthogrid. Note the circumferential blade stringers, which are later welded to the frame. Source | GKN Fokker

The GKN Fokker/Gulfstream team knew it was infeasible to meet the challenges created by a complex curvature either with metal or with conventional composite design-manufacture approaches. In particular, Buitenhuis points out, “A complex fuselage design would not be possible without fiber steering.” This capability of AFP machines is what freed the designers to optimize fiber orientation locally based on the shell’s complex shape, and to diverge from the standard 0/45/90 fiber orientation options. “Fiber steering for shapes and weight optimization is one of the most significant advancements of this project,” Chapman believes.

GKN Fokker made the fuselage panel’s skin on an ultrasonic AFP machine that the company developed for rapid thermoplastic tape layup. The tape is unidirectional, which also enhances laminate performance compared to fabric tapes.

Successfully handling the high loads created by cabin pressure and impact forces, as well as other performance demands, the new concept developed under TAPAS and TAPAS2, and that is now employed in the Gulfstream panel, is what is described as a “butt joint orthogonally stiffened skin with welded frames.” Unpacking this description highlights three key design features and the manufacturing developments needed to implement them: (1) the orthogrid, (2) the butt joint and (3) welding technology.

Orthogrid

The panel’s strength requirements are met in part through fully interconnected orthogonal grid stiffening. This orthogrid eliminates the peak loads associated with the mouse holes, ridding the design of points at which peel forces are magnified. The orthogrid consists of continuous longitudinal stringers and frames comprising two distinct components: discontinuous but connected circumferential blade stringers and frames welded on top of these.

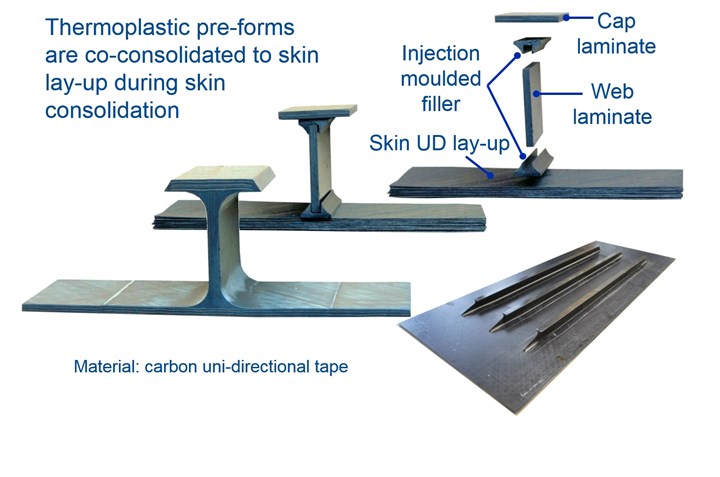

Cost-effective butt joint. GKN Fokker innovated and patented a butt joint that enables orthogrid and orthogrid-to-skin joining using cost-effective short-fiber injection molded elements and continuous-fiber flat laminates for the stringer web and cap (here a T stringer; the Gulfstream panel incorporates L stringers with the same technique). Source | GKN Fokker

Thus, this represents a new generation in fuselage stiffener design which has evolved during years of orthogrid development. Initially, GKN Fokker used T stringers in which the caps of both longitudinal and circumferential members were continuous and overlapped at the corners. Joining with the frame, however, required the removal of the circumferential cap. Thus, T stringers became L stringers and frames became circumferential blade stringers with frames then welded to them.

Another modification is required because the curved stringers used both longitudinally and circumferentially make tool release much more challenging. Thus, the L stringers are designed with a cap-to-web angle of more than 90 degrees, so that tool pieces can always slide sideways out of the stringer grid.

Butt joints

GKN Fokker developed not only the orthogrid design, but also a new manufacturing approach for the grid as well as the grid-to-skin joining mechanism. “The grid can be prohibitively expensive to fabricate,” Offringa notes, “but our grid is built up of flat laminates and simple injection molded ‘fillers.’”

More specifically, GKN Fokker applied its patented butt joint technology to the Gulfstream panel (also to the preceding TAPAS panels). The web and cap of the T or L stringer components, as well as the blade stringer components, are fabricated from preforms that are waterjet-cut from a flat carbon fiber/PEKK laminate. The joining elements (skin to web and web to cap) are injection molded, pi-shaped filler made from a short-fiber carbon/PEKK material. Both the resin and the carbon fiber type match those in the grid members.

Skin and orthogrid are co-consolidated in an Invar inner mold line (IML) tool. The tool features grooves into which the orthogrid components and tooling blocks are loaded. The AFP-formed skin is then placed on the IML, and the entire assembly is bagged and autoclave-consolidated.

Welding

Automated welding. Contributing to the economic feasibility of the thermoplastic composite fuselage panel, GKN Fokker developed and employed a robotic welding technique. Source | GKN Fokker

The combination of the orthogrid and butt joint design enable fastener-free joining of the orthogrid and frame via welding. Several welding technologies were developed by TAPAS team members during the TAPAS2 phase, including induction, conduction and ultrasonic welding technologies. The Gulfstream panel employed conduction welding to join the frame web to the circumferential blade stringer. This task is performed with the weld head mounted to a robot — another development that contributes to cost-effective manufacturability.

One step of several

GKN Fokker started its collaboration with Gulfstream in 2017, creating design concepts for the fuselage panel. Design and fabrication of several curved panels followed in 2018 and 2019, with the milestone first panel demonstrator displayed at this year’s JEC World.

Completed component. With frame elements welded to the circumferential blade stringers, the Gulfstream fuselage panel is ready for testing, assessment and continuing development as the companies work toward production thermoplastic composite fuselages. Source | GKN Fokker

GKN Fokker is continuing to build panels and expects to achieve TRL4 (component validation) later this year. “We are currently discussing the way forward to full maturity,” Offringa reports. Pointing out that the panel design does not target a particular platform, Chapman reports that panel testing will help deepen Gulfstream’s understanding of material properties and performance. Regarding the broader business case for thermoplastic composite primary structures, including the jet’s performance, manufacturing cost, cost in use and durability, Chapman remarks, “We will get a better understanding of those as we get further down the research-and-development road. For now, our focus is on making these complex shapes cost effectively.”

Related Content

Clean Sky 2 OUTCOME project demonstrates PEEK thermoplastic composite wingbox cover

Airbus Defense and Space, FIDAMC and Aernnova demonstrate out-of-autoclave, one-shot process for wingbox cover with integrated stringers for regional aircraft.

Read MoreMarkforged develops composite 3D printing technology

The FX10, a composite 3D print system with built-in automation, and Vega, a carbon fiber-filled PEKK material from Markforged, expand on 3D printing applications for customers.

Read MoreQueen’s University Belfast presents research in thermoplastic drilling performance optimization

Researchers have published findings from a multi-objective optimization study on carbon fiber-reinforced PEKK drilling in an effort to better understand the material for use in aviation fastenings.

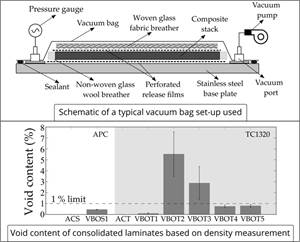

Read MoreTPRC research studies void removal mechanisms in VBO processing

New publication evaluates vacuum bag only-consolidated carbon fiber/PEEK tapes to determine the role of different void removal mechanisms in thermoplastic composites.

Read MoreRead Next

Next-Gen Aerospace Special Edition

Read the Next-Generation Aerospace Special Edition, produced in partnership with CompositesWorld, Modern Machine Shop and Additive Manufacturing.

Read MoreSpirit AeroSystems debuts next-generation composite fuselage panel

The 18-by-12-foot (5.5-by-3.7-meter) demonstrator panel debuted at the Paris Air Show features integrated skin and stringers and offers substantial cost savings combined with strong performance attributes.

Read MoreOpportunities, challenges for composites in future aircraft

As the commercial aerospace sector prepares for a new round of major program launches, the question of where and how composites will be applied weighs heavily on the supply chain.

Read More