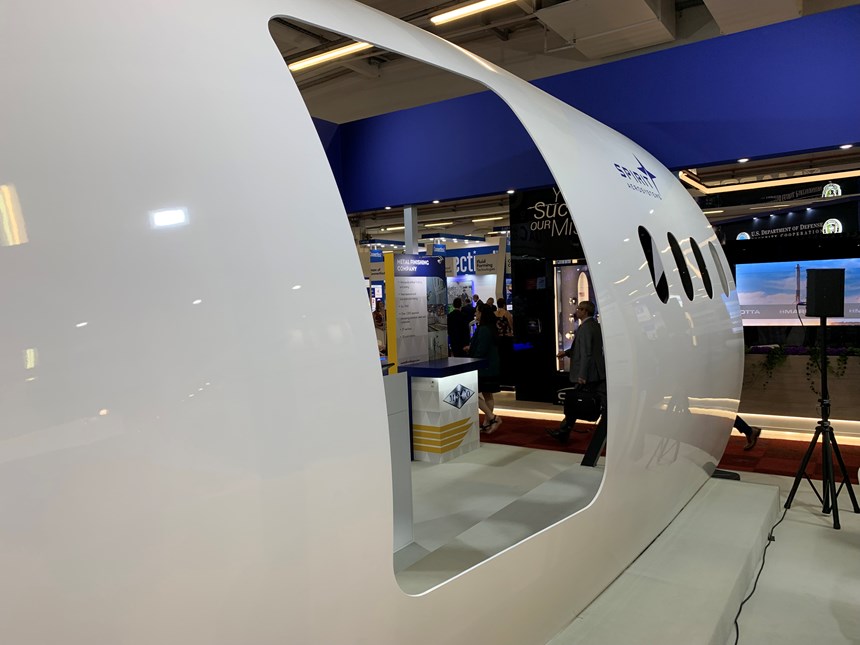

Spirit AeroSystems (Wichita, Kan., U.S.) debuted on Monday, June 17, at the 2019 Paris Air Show (Paris, France), a new composites manufacturing technology designed specifically for next-generation, high-volume, single-aisle fuselage production. The technology was shown at the exhibition in the form of an 18-by-12-foot (5.5-by-3.7-meter) demonstrator fuselage panel — dubbed ASTRA (Advanced Structures Technology and Revolutionary Architecture) — that features integrated stringers fabricated using a novel material/process combination with cost savings of 30% compared to incumbent architectures and production system approaches. “To me, this is a great testament to what Spirit can do,” says Eric Hein, senior director, research and technology, at Spirit AeroSystems.

Hein says that almost two years ago, the company began looking at the potential needs of a next-generation single-aisle fuselage and identified design and M&P challenges that would have to be overcome to make composites a viable choice for aircraft manufacturers.

First, he says, is the matter of rate. Boeing and Airbus estimate production volumes of 60-100 aircraft for next-generation single-aisle replacements for, respectively, the 737 and the A320. The composites-intensive Boeing 787 and the Airbus A350 are currently manufactured at rates of about 14 and 10 per month, respectively. A next-generation manufacturing technology, therefore, would have to meet a production pace that is four to 10 times faster than incumbent technology.

Second, Hein says, incumbent composite materials and configurations applied to a single-aisle aircraft are weight- and cost-prohibitive compared to aluminum. Therefore, to make next-generation composite fuselage skins more competitive, says Hein, they would have to be several plies thinner — and still meet all applicable impact and load requirements.

So, for the last 18 months, Spirit AeroSystems has performed trade studies and developed design values for a wide spectrum of M&P combinations, designed to assess which combination offers the most feasible path to meeting the rate and cost targets Hein identified. For rate, the company assumed 60 shipsets per month. For cost, the company assumed equality with incumbent metallic materials. The trade studies, Hein says, assessed autoclave-cured prepregs, liquid resin infusion (including resin transfer molding), and thermoplastic composites. All showed potential viability in a next-generation single-aisle aircraft. “We believe there is a future for a composite plane that can be made at rate cost-efficiently,” Hein says.

The combination Spirit AeroSystems picked for the ASTRA demonstrator was autoclave-cured prepregs, because it provided the most manageable path to the cost and rate targets identified. Hitting these targets, however, depended on some novel thinking about tooling configuration as well as panel architecture.

To reduce tooling costs, Spirit AeroSystems decoupled the mold face from the mold support structure. In doing so, the company opted for a lower cost metallic support structure, and then developed a “floating” bismaleimide (BMI) mold face sheet that rests on that structure. This allows mold investment to be focused where it matters most — on the part-making surface.

The most innovative aspect of the panel might be the design of the integrated skin and stringers, which represents a significant departure from traditional composite fuselage skin/stringer architecture. For both the 787 and the A350, fuselage stringers are fabricated separately and then inserted into fixtures/slots in the fuselage skin tool. These are then overwrapped with unidirectional carbon fiber prepreg applied via automated fiber placement (AFP) to build the skin laminate. The entire structure is then co-cured in autoclave. The 787 design specifies the fuselage be fabricated in barrel segments. The A350 design specifies the fuselage be fabricated in panel segments.

Hein says that one of the challenges of current skin/stringer construction is that each stringer, although co-cured with the skin, is a discrete part that creates a discontinuity between stringer locations. To overcome this, he says, often a carbon fiber composite laminate a few millimeters thick is attached to the inner surface of the fuselage skin to fill the gap between each stringer, thereby providing stringer-to-stringer continuity. In addition, at the ends of stringers, this discontinuity is commonly addressed through the use of fasteners.

The ASTRA design bypasses this architecture with what Hein describes as “sheet stringer technology.” With this technology, stringers are fabricated from carbon fiber prepreg sheets placed first on the slotted fuselage mold face. Then, using vacuum forming, the sheet is drawn into the stringer channels, creating, in effect, a corrugated stringer panel. Then, as is done now, the fuselage skin is overlaid via AFP, followed by autoclave cure. The result is a fuselage panel with a continuous inner skin featuring fully integrated stringers.

With this tooling strategy and panel architecture established, Spirit AeroSystems then embarked on a test regime in partnership with the National Institute for Aviation Research (NIAR) at Wichita State University designed to assess different fiber combinations in the skin and in the sheet stringer. The company tested for impact resistance, strength, fatigue, environmental shock, lightning strike, FST (flame, smoke, toxicity) and damage tolerance. Hein says the ASTRA fuselage structure it developed passed all of the structural tests and meets the reduced ply thickness that the company targeted.

The ASTRA panel on display at the Paris Air Show (in the Kansas Dept. of Commerce stand, Hall 3, C98) features a skin fabricated using Toray’s (Tokyo, Japan) T1100/3960 carbon fiber prepreg, applied using an Electroimpact (Mukilteo, Wash., U.S.) AFP system that also provided tow steering (6-inch radius) around the corners of the door opening. Spirit recently completed its own allowables program for the Toray prepreg, enabling Spirit to offer a head start to customers. The stringers were fabricated with one of two material types to demonstrate the flexibility of the design:

- A&P Technology’s (Cincinnati, Ohio, U.S.) QISO braided, quasi-isotropic carbon fiber fabric prepregged with Toray’s 3960 epoxy resin matrix

- Unidirectional tapes made with Toray’s T1100/3960 carbon fiber prepreg

Hein says that the ASTRA fuselage structure Spirit AeroSystems has developed is best suited for a panel-based fuselage architecture, but that it can be adapted for a barrel-based architecture as well. The bottom line, says Hein, is that he feels like Spirit AeroSystems is prepared to help aircraft manufacturers move forward with cost-effective composite structures in a high-volume manufacturing environment. Further, the company has developed a manufacturing layout that it says can meet the >60-shipsets-per-month requirement of a new single-aisle program.

“As far as the building block for the basic configuration, we have answered all the up-front questions,” Hein says. “We have something that is weight-competitive with current metallic fuselage structures, and offers 30% savings compared to current composite fuselage structures, addressing both initial investments and recurring costs. Obviously, our goal is to get on something [aircraft program] early. Acceptance is there, but we still have some runway in front of us. Ultimately, I think customers will demand a composite fuselage.”

Related Content

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MorePlant tour: Arris Composites, Berkeley, Calif., U.S.

The creator of Additive Molding is leveraging automation and thermoplastics to provide high-volume, high-quality, sustainable composites manufacturing services.

Read MoreHexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More