Thermoplastics riding into automotive, aerospace

The legacy of composite parts and structures is built on a family of thermosets — including epoxy, vinyl ester, polyester and phenolic — that have helped tremendously to make the industry what it is today. Not to be forgotten are thermoplastics, which have played a serious role as well, and offer advantages that promise to make this material type one of the fastest growing over the next decade.

Thermoplastic composites specialist Daher-Socata compression molds these fuselage clips in its Nantes, France, plant for the Airbus A350 XWB using TenCate Advanced Composites' carbon fiber/PPS preconsolidated blanks. Each aircraft uses hundreds of clips and Daher-Socata has developed a solid reputation for making high-quality parts to spec. Thermoplastic composites are expected to more and more use in aerospace applications — including in primary structure — over the next decade.

The legacy of composite parts and structures is built on a family of thermosets — including epoxy, vinyl ester, polyester and phenolic — that have helped tremendously to make the industry what it is today. Not to be forgotten are thermoplastics, which have played a serious role as well, and offer advantages that promise to make this material type one of the fastest growing over the next decade.

The upsides of thermoplastics have been well documented, but are worth reviewing all the same. Topping the list is the fact that they are melt processed, which makes their pre-processing storage and handling easier to manage, particularly compared to prepregged thermosets, which require cold storage and limited out time. Thermoplastics, because they can be reheated and reformed, are significantly easier to recycle, which has appeal across a number of end markets. Third, thermoplastics are typically (but not necessarily) processed out of the autoclave, which makes them energy and cycle-time friendly. Fourth, the processes normally associated with thermoplastics — injection molding, compression molding — are widely used and well understood by a variety of processors and OEMs. Finally, thermoplastic materials, in general, offer greater toughness in the finished part than thermosets do, and some thermoplastic materials offer a higher end use temperature than the thermosets against which they compete (i.e., epoxies).

Thermoplastics, however, are not without their challenges, the primary being that the thermoplastic resins (PEEK, PAEK, PEI) that provide the same strength as many thermosets do can be substantially more expensive. This is a hurdle in end markets, like automotive, that are more price-sensitive. Still, thermoplastics’ benefits are sufficiently attractive that they have become the subject of substantial research and development work over the last 5-10 years.

The end markets most interested in thermoplastics — and the ones that stand to benefit the most — are automotive and aerospace. For automotive, the attractions are several: Cycle time, recyclability, familiarity. The latter grows out of the fact that the automotive industry already has decades of experience using thermoplastics like nylon and ABS everywhere from underhood parts to bumper fascia. Applying resins like these in composite structures seems like a natural next step.

For aerospace, thermoplastic materials offer processors and OEMs a chance to get out of the autoclave, which has become a workflow bottleneck in the manufacturing process. In addition, the capital and operational expense associated with the autoclave is substantial. In aerospace, however, consolidation is king, and <1% porosity is the standard. Autoclave processing is the best, most effective way to meet that requirement. Nonetheless, thermoplastics are earning a larger slice of the commercial aircraft pie.

Automotive thermoplastic composites

Despite the auto industry’s familiarity with thermoplastics, application of composites in structural parts cars and trucks has focused primarily on the use of thermosets — mainly epoxy. Indeed, the first mass-produced vehicle to use carbon fiber composites in the body-in-white, the BMW i3, relies on a fast-cure (~5 minutes) epoxy developed by Huntsman Advanced Materials. Other epoxy suppliers, like Hexcel, Hexion, Dow Automotive and Cytec Solvay have developed fast-cure epoxies for similar applications.

The future, however, might be in thermoplastic composites, particularly given the European Union’s material recycling mandates. The most compelling thermoplastic composite technology for automotive use has come from carbon fiber manufacturer Teijin, which worked with General Motors to develop what it calls Sereebo.

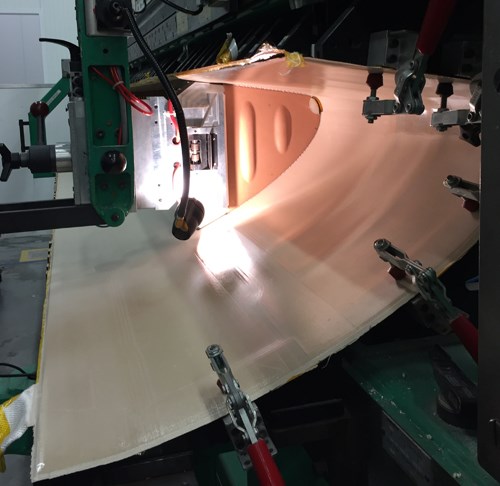

This automotive panel in the Teijin stand at JEC 2016 is designed to demonstrate the deep-draw, high-detail capabilities of the company's thermoplastic-based Sereebo process.

Eric Haiss, vice president of Teijin Advanced Composites America Inc. (Auburn Hills), sayst the Sereebo process combines a nylon 6 resin matrix with a mat of chopped carbon fibers (length ~20 mm), which are preheated and then molded/formed in a standard compression molding machine in cycle times of 60-80 seconds. Haiss says Teijin cannot reveal the form the nylon 6 takes, except that it is integrated in the carbon fiber mat. In addition, the carbon fiber will be sized for the nylon 6 resin.

Parts on display in the Teijin stand at JEC World 2016 indicate the Sereebo process is capable of producing parts with relatively deep draws and large curvatures, with no wrinkling. In addition, changes in mat thickness allow for tailored fiber reinforcement to meet specific mechanical load requirements. Further, says Haiss, the way the fiber is oriented in the mat, isotropic properties can be moderately controlled.

Data displayed on the Teijin stand at JEC indicate that parts made with Sereebo exhibit significant energy-absorbtion properties: 70 J/g, compared to 59 J/g for continuous carbon fiber composites and 20 J/g for aluminum.

Another Teijin part to demonstrate the deep-draw capabilities of Sereebo.

Haiss says the Sereebo process will be used by Teijin to fabricate primary structure automotive parts for an undisclosed automotive program. The model year of the vehicle was not revealed. Teijin also would not identify the OEM involved, but Teijin's history of cooperation with GM makes that carmaker the most likely customer. Fabrication will be done in the United States, but a location has not yet been determined. Haiss did say that fabrication will not be done in Auburn Hills.

Beyond compression molding, there is substantial work being done to develop multi-material injection molding, or hybrid molding. In this process, a preformed continuous reinforcement, carbon or glass, is inserted into an injection mold. Around this preform is injected a thermoplastic material, like nylon or ABS, creating a finished thermoplastic composite with continuous reinforcement. The challenge of this process, however, is the pressure at which the resin is injected, which can displace or damage the fibers. Also a challenge is full fiber wetout, which can be hindered by the relatively high viscosity of traditional engineering thermoplastic resins. Several injection machine manufacturers are working on this technology, including Engel, KraussMaffei and Arburg.

Aerospace thermoplastic composites

The commercial aircraft industry only recently committed to composites use in a serious way, with the application of carbon fiber/epoxy composites in >50% of aircraft primary structure on the Boeing 787 and the Airbus A350 XWB. Thermoplastics have been employed in a few notable structures, most importantly the wing leading edge of the Airbus A380 super jumbo jet and the rudder/elevator for the Gulfstream G650 business jet.

Airbus A380 thermoplastic composite wing leading edge fabrication at Fokker Aerostructures' plant in Hoogeveen, The Netherlands. In this process step, ribs are inserted and welded to the inner skin of the leading edge.

Both of these parts are manufactured by Fokker Aerostructures (Hoogeveen, The Netherlands), which has made a name for itself developing thermoplastic structures for the commercial aircraft industry. However, Fokker still relies on an autoclave to consolidate its thermoplastic parts. Thus the market for out-of-autoclave (OOA) thermoplastic parts production is still in its youth.

One interesting development underway is being led by the Composites Research, Development and Application Centre (FIDAMC, Getafe, Spain), which has spent the last few years researching how to lay a thermoplastic wing skin with integral stringers. In the most recent project completed, called ISINTHER, FIDAMC laid blanks on a flat tool, with an isotropic layup, using an MTorres (Torres de Elorz, Navarra, Spain) layup head that has laser heating and a conformable roller to consolidate the layup.

This flat stock was then press-formed with heat to make a hat stringer (omega-shaped). These omega stringers were then inverted and placed in a tool with depressions that received the stringers, so that the base of each omega stringer was flush with the flat tool. Over this FIDAMC laid the wing skin, joining/melting the skin and stringer together, out of autoclave. The material used is Cytec Solvay APC2/AS4 carbon fiber with PEEK. FIDAMC plans to produce an entire wing section that, it hopes, will fly on a military plane in 2020.

Thermoplastic composites in rotorcraft

A strong advocate of thermoplastic composites, David Hauber, VP of Engineering at Automated Dynamics (Schenectady, NY, US), is working diligently to dispel what he calls the “myth” of the necessity for <1% porosity (void content) in composite aerostructures. “The key is not porosity,” he contends. “It’s performance. Tough thermoplastic materials are much less sensitive to porosity than their more brittle thermoset counterparts.”

For proof of this, Hauber points to work Automated Dynamics has done developing a thermoplastic driveshaft for helicopter use that offers a 35% weight reduction compared to its aluminum predecessor, with 150% post-ballistic torque to failure — all with 4% porosity. The project was funded by a Navy Small Business Innovation Research (SBIR) Phase II grant that partnered ADC with SURVICE Engineering (Belcamp, MD, US) and UTC Aerospace Systems (UTAS, Rome, NY, US).

This helicopter driveshaft was developed by Automated Dynamics, uses carbon fiber/PEEK. It's intended to prove the mechanical capabilities of thermoplastic composites and performed exceptionally well in high-speed projectile tests.

The driveshaft is composed of a carbon fiber/polyetheretherketone (PEEK) prepreg that features HexTow IM7 fiber, from Hexcel (Stamford, CT, US). The prepreg is in-situ placed via an automated fiber placement (AFP) system developed by Automated Dynamics, on a cylindrical aluminum mandrel. The system’s short heat-affected zone and high pressure applied at laydown produces a shaft that is immediately and fully consolidated, with, says Hauber, no post-process work required to finish cure.

After consolidation, the shaft is removed from the mandrel, trimmed and sent to UTC Aerospace Systems, where end-fittings are added and testing begins.

The shaft’s key performance metric is how it responds in a ballistic environment, and this, says Hauber, is what led the customer to thermoplastics in the first place. “The initial impetus for going to thermoplastics for this shaft was for better operational durability,” he points out.

To assess the ballistic response, SURVICE simulates what Hauber says is considered the worst possible damage a shaft might endure: a glancing blow from a high-speed projectile. The shaft is then tested to failure in a damaged state; the Automated Dynamics shaft, reports Hauber, failed at 150% of the required value. Feedback has been very positive; the next step will be testing the shaft in an operational environment, with a goal of TRL 6.

Hauber acknowledges that thermoplastic composites advocates have a long row to hoe convincing the aerospace industry that product performance trumps porosity values. This is particularly challenging given the long qualification cycles a material must endure before it is approved for commercial use: “It’s very expensive to characterize and qualify a new material,” he says. “The challenge is to overcome the perceived risk by demonstrating improved performance in a demanding operating environment.”

No matter the application, the appeal of thermoplastic composites is obvious. Given the amount of research and development work being done now, combined with the market pull from automotive and aerospace, it’s fair to say that thermoplastics will play a major role in the growth of the global composites industry.

Related Content

Plataine unveils AI-based autoclave scheduling optimization tool

The Autoclave Scheduler is designed to increase autoclave throughput, save operational costs and energy, and contribute to sustainable composite manufacturing.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreBusch expands autoclave solutions

Busch announces its ability to address all autoclave, oven and associated composites manufacturing requirements following the acquisition of Vacuum Furnace Engineering.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More