Tidal turbine blade toughened for turbulent salt sea

Demonstrator design proves robust blade destined for 10-MW tidal turbine farm.

Engineering Challenge:

Design a tidal turbine blade that can withstand the density, pressure, temperature and dynamic physical environment of a subsea location.

Design Solution:

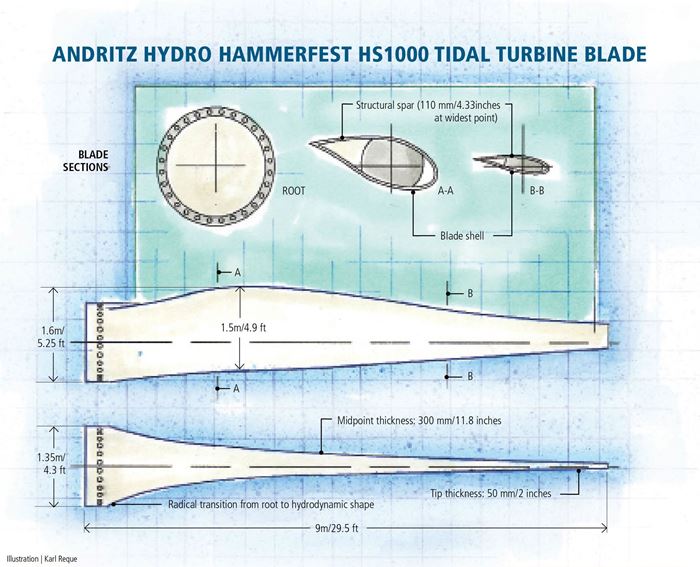

A blade that is shorter and of relatively greater thickness than its cousin in the wind energy sector, with an aggressive transition from the circular root to hydrodynamic architecture.

It would be nice if designing a composite blade for a tidal turbine were as simple as putting a wind turbine blade under water. But, of course, it’s not.

When the composite structure of a turbine is to function fully submerged in saltwater for a long period of time, the blade’s designer must consider a host of differentiating factors: While a wind blade has to withstand occasional rain or snow, a tidal turbine blade must handle continuous submersion in highly corrosive saltwater. Water temperature and, especially, pressure, density and turbulence require much greater strength and durability. And the presence of sea creatures — many much larger than the birds that sometimes collide with wind blades — and a variety of underwater plant life, boats and other marine craft present many more potential hazards than wind blades are likely to encounter.

Gurit (Newport, Isle of Wight, U.K.) faced this multifaceted challenge when it was approached by ANDRITZ HYDRO Hammerfest (Hammerfest, Norway) to develop composite blades for the company’s newest tidal turbine, the HS1000, a 1-MW system destined for placement in waters controlled by the European Marine Energy Centre (EMEC), located near the Orkney Islands off the northern coast of Scotland. ANDRITZ HYDRO Hammerfest had designed, built and tested a smaller predecessor, the HS300 (rated at 300 kW), in waters off the coast of Norway and was looking to scale up that design as the next step in its progression to a 10-MW tidal turbine farm in the Sound of Islay off the west coast of Scotland.

The HS1000 that was installed at EMEC would be a precommercial demonstrator, used for testing and certification in the lead up to full deployment in the Sound of Islay. A big part of that certification process is dependent on blade performance. The blades are expected to function for many years — the turbine as a whole is designed for 25 years of service with only minimal maintenance — similar to the expectation for wind turbines, but in a much more dynamic and rigorous environment.

So many variables

Marcus Royle, Gurit’s engineered structures business development manager, says the underwater environment in which the HS1000 operates dictates a blade design that is, in many subtle ways, very different from the type of blade found on a typical wind turbine.

One of the biggest differences, of course, is water density, which is about 1,025 kg/m3. By comparison, the air, depending on pressure and temperature, ranges from about 1.1 to 1.4 kg/m3. The difference — about a factor of 800 — represents a substantial physical load for a blade, thus it must be more stout to provide continuous service. “We have to cram a lot more material into the blade to make it structurally viable,” Royle quips. Further, he notes that the composite materials used in the blade have a natural tendency to absorb water, which over time can compromise the strength of the blade. “We must design the blade to accommodate the reduction in strength,” he notes, “so that the blade at the end of life is still strong enough.”

“Cramming” more material into the blade meant designing a shorter blade (9m/29.5 ft) than would be required for a wind turbine of the same 1-MW capacity (30m/100 ft rotor diameter). And because the blade is relatively short, it also means that the blade design must transition much more quickly than a wind blade does from the cylindrical shape at its root to its sculpted hydrodynamic architecture (see illustration, top left).

“The more aggressive that transition,” says Royle, “the more difficult it is to get the load out of the root and into the spar cap to make sure we don’t have large concentrations of stress.”

Another variable that Gurit had to contemplate was water pressure — 1 bar/14.5 psi per 10m/32.8 ft of water depth. Most tidal turbines, says Royle, are located about 40m/131 ft deep to remain clear of marine craft that pass overhead. This represents pressure of about 4 bar/58 psi. The HS1000 blades, however, are designed for depths to 100m/328 ft.

Finally, Royle says, Gurit had to consider the challenge of coping with the pressure differential between the inside and the outside of the blade — air pressure of 1 bar/14.5 psi vs. water pressure of 10 bar/145 psi. To maximize blade-turning and power-generating efficiency, Royle says, it was necessary to equalize the pressure in some way. Gurit, he reports, considered several ideas, including filling the blades with water prior to installation, filling the blades with foam or flooding them with seawater. The selected solution, however, is considered by Gurit to be subject to confidentiality and, therefore, was not disclosed.

Dimensions, tools, materials

The blade that Gurit ultimately designed for the HS1000 measures 9m/29.5 ft long, weighs 2,000 kg/4,409 lb, is 1.5m/4.9 ft at its widest point and has a root that is 1.3m/4.3 ft in diameter. The blade is 300 mm/11.8 inches thick at the center and 50 mm/2 inches thick at the tip. Designed for water flows of up to 5m/sec (16.4 ft/sec), the turbine’s 1-MW rating equates, practically, to power that is sufficient for about 500 homes. To capture tidal water energy as it ebbs and flows, the turbine remains stationary, but the blades can be adjusted to rotate through 270° to accommodate the change in water flow.

Beyond the environmental challenges, Royle says Gurit focused its engineering efforts on developing a blade that is commercially viable. Although the first HS1000 is a pre-commercial product only, ANDRITZ HYDRO Hammerfest has firm intentions of developing a full-scale tidal energy field very soon. Therefore, says Royle, “We had to come up with a blade design that could be built for series production. Our primary aim was a blade that wouldn’t fail and would be commercially viable.”

Initial blade design was accomplished with software Gurit developed in-house, Royle says. But when the initial concepts were complete, the company employed Patran and Nastran (both from MSC.Software, Santa Ana, Calif.) and Hyperworks (Altair Engineering Inc., Troy, Mich.) to evaluate and virtually test each concept.

The blades themselves consist of a mix of glass and carbon fiber prepregs, all oven-cured. The spar caps (110 mm/4.33 inches at the thickest point) are manufactured using Gurit’s trademarked SparPreg unidirectional carbon fiber prepreg — designed specifically for use in spar caps — combined with the company’s trademarked SPRINT glass fiber prepreg, also designed for blade applications. These materials reportedly allow the very thick laminates of the spar to be built up and cured in one shot under vacuum pressure only, without debulking to remove air between plies. The blade shells are sandwich constructions, featuring trademarked SPRINT glass fiber pregreg faceskins surrounding Gurit’s trademarked Corecell structural foam for the core. Molded in one-shot halves, the shells, when assembled, encapsulate the spar cap and are bonded together with Gurit’s Spabond toughened epoxy structural adhesive.

Gurit built four blades for the pre-commercial HS1000 demonstrator — three for the turbine and the fourth for load testing on land.

The turbine was installed at EMEC in December 2011 and started generating electric power at full capacity in early 2012. Per ANDRITZ HYDRO Hammerfest’s requirements, Gurit included strain gauges on the blades to assess their performance during operation. Royle declined to reveal specifics regarding blade performance to date, except to say “so far, performance is exactly as we hoped and expected.”

The first phase of the commercial tidal energy farm comprises 10 1-MW turbines, which will be installed in the Sound of Islay. This project will be followed by another, a 95-MW tidal turbine farm in the waters near Duncansby Head, north of Scotland, not far from the EMEC.

Royle says ANDRITZ HYDRO Hammerfest is working on designs for the 10 Islay turbines now and expects to make some slight design modifications because water flow in the sound is slower than the flow at the EMEC site. If permitting, testing and certifications proceed as planned, the commercial tidal farm will be operational by 2015.

Among the lessons learned by Royle during development of the HS1000 blade? “Just how aggressive the tidal seawater environment is,” he observes, “and how it affects just about every aspect of the design.”

Related Content

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreHexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

Read MoreWatch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More