Ultrathin sandwich panels come to market

These 0.2-mm-thick carbon fiber/foam sandwich structures have been developed by North Thin Ply Technology and 4a manufacturing.

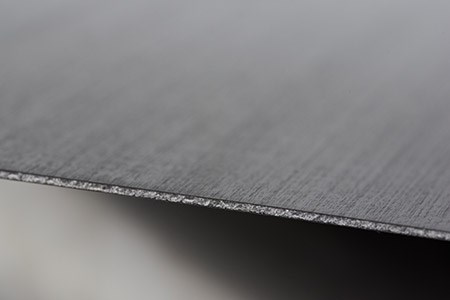

NTPT ultrathin sandwich material.

North Thin Ply Technology (NTPT, Renens, Switzerland), a lightweight prepreg materials specialist, has recently begun an collaboration with 4a manufacturing (Traboch, Austrial), a specialist in thin foams and micro sandwich materials for acoustic and lightweighting applications.

For more than 10 years, 4a manufacturing has produced tight-tolerance hard foam sheets — under the MILLIFOAM brand — as thin as 0.2 mm, and combining them with metal skins to form ultra-thin CIMERA sandwich materials. These materials are used to increase stiffness with no added weight, or to maintain stiffness while reducing weight and saving material across a diverse range of markets from micro-speakers in consumer electronics to ultra-light sports equipment.

NTPT and 4a began to work together earlier this year when 4a sought to increase the stiffness of the aluminum sandwich skins in materials for high-performance micro-speakers typically used in mobile devices such as lap tops, mobile phones and tablet computers. One of the main challenges for prepreg materials in these thin sandwich structures is maintaining uniformity of the carbon fiber layers, and this has become an even more critical property as ply weights decrease. NTPT’s fiber-spreading capability facilitates highly uniform UD prepreg tapes with areal weights as low as 15 gsm, and it was this thickness control, and expertise with ultra-high modulus fibers (>300 GPa), that led to the development of a unique new CIMERA micro sandwich using a 20-gsm (0.02 mm-thick) prepreg and a total thickness of less than 0.2 mm.

The two companies can offer customers flat panel carbon fibre CIMERA micro sandwich laminates (direct from 4a manufacturing) or a materials package of NTPT thin-ply prepregs and MILLIFOAM cores, for those wishing to mold their own ultrathin 3D sandwich components. TPT preforms — stacks of unidirectional prepreg plies laid down via automated tape laying (ATL) the angles defined by NTPT engineers and the customers’ technical team, can also be used with 4a manufacturing cores to improve accuracy and reduce mold draping time for lightweight sandwich parts.

Related Content

-

Carbon Mobile, SABIC to develop, deploy advanced carbon fiber in connected devices

Collaboration aims to deliver the next generation of thinner, lighter, stronger and more sustainable composite materials used in consumer electronics and automotive industries.

-

Composites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

-

Syensqo launches Swyft-Ply brand for electronics, smart devices

Multifunctional composites leverage traditional advanced material benefits while meeting specific industry manufacturing and performance requirements.

.jpg;maxWidth=300;quality=90)