Urban turbine redesign taps benefits of additive fabrication

Michael R. LeGault details efforts to produce an anti-icing system for “small-wind” vertical-axis wind turbine blades.

According to the American Wind Energy Assn. (Washington, D.C.) small wind turbines — those that generate 100 kW of electric power or less — serve a renewable energy market segment forecast to grow by 40 percent annually over the next two decades. To more effectively tap the potential of this “small wind” sector, Wind Sweeper Turbines, a joint venture of Urban Green Energy Inc. (New York, N.Y.) and Aviradyne Technologies Inc. (Layton, Utah), has been formed to build next-generation vertical-axis turbines, based on existing Urban Green turbine designs. More compact than the horizontal-axis, propeller-style turbines used in utility-scale wind farms, these much smaller, (under 10 kW) turbines are well suited to urban and suburban settings — they mount more easily on existing buildings and can be integrated, architecturally, into new building designs.

Urban Green’s current glass/epoxy turbine blades will be replaced by a carbon fiber/epoxy construction that will accommodate anti-icing heat exchangers. The new design will address concerns about ice build-up on often unattended, small wind turbines. Ice can cause uneven wear on turbine bearings and induce stress loads, resulting in catastrophic failure. A second goal is to increase blade strength-to-weight ratio by 20 percent.

New mission, new method

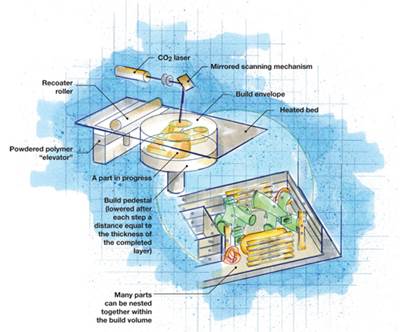

The key to cost-effective manufacture will be Direct Digital Advanced Composite (D-DAC) technology, developed by Dynastrosi Laboratories (Bowling Green, Ky.). D-DAC is a patented method for producing a sandwich structure that consists of fiber-reinforced skins bonded to a complex core material that is produced to net shape by a process called additive fabrication. Also known as rapid manufacturing, additive fabrication refers to a number of advanced forms of rapid prototyping (RP) that employ free-form (or tool-less) methods of building three-dimensional (3-D) models directly from CAD design data. (For background on additive fabrication, see “The Rise of Rapid Manufacturing,” in this issue, on p. 32).In June, Dynastrosi merged with Aviradyne Technologies Inc. The new joint venture will be a D-DAC licensee and will use the method to fabricate next-generation small-scale, vertical-axis turbines based on existing Urban Green turbines presently manufactured by its subsidiary, Beijing Urban Green Energy Ltd. in Hebei Province, China. Ronald Jones, Aviradyne’s chief technology officer, says the goal of the project is to develop and build urban-friendly wind turbine systems while concurrently reducing manufacturing costs. When design optimization and prototyping is completed (in 12 to 18 months), the D-DAC production process is expected to be cost-efficient enough to permit manufacture at a U.S. site. Jones says a decision on the final plant location will be reached sometime in late summer. The prototyping project will entail a redesign of the blades on either Urban Green’s 2nd Generation 1-kW or 4-kW Darrieus-style wind turbines, now marketed as the UGE-1K and UGE-4K, respectively. The blades are thin airfoils or “swept wings,” each approximately 9.0 ft/2.75m in length, which sweep with constant curvature in a graceful 120° partial spiral from top to bottom. The turbine’s three blades, each attached to a center shaft by a set of interconnected struts (see inset photo, above), produce rotational torque by aerodynamic lift when the wind reaches its cut-in speed of about 7 mph. Unlike other Darrieus-style turbines, the UGE turbines start on their own without a “kick start” from the generator, which doubles temporarily as a starter motor. This wind turbine design is considered ideal for the types of turbulent air found in most urban centers and also is able to operate at much higher wind speeds than competing horizontal axis turbines: The UGE-4K wind turbine reaches its maximum rpm at 45 mph wind speed, but is reportedly able to tolerate winds as high as 125 mph.

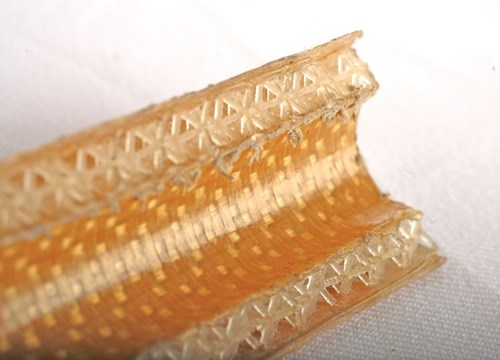

Currently, the blades are made of glass-fiber laminate skins layed up over glass-fiber ribs, reinforced with carbon fiber spars. In the redesigned anti-icing-capable variant, a sandwich structure made from self-supporting net-shaped thermoplastic core will be overlaid with plies of bidirectional carbon-fiber weave impregnated with epoxy resin. During the design phase, heat-exchange conduits (tubular and rectangular designs are being considered) will be “woven” into the core’s reinforcing pattern near the inner side of the faceskins on the leading edges of both the blades and their support struts. Heated air, transported under low pressure through the conduits, will keep blades ice-free.

Core construction competitors

For core construction, Jones says the company is presently evaluating three additive-fabrication platforms and respective materials: Stratasys Inc.’s (Eden Prairie, Minn.) Fused Deposition Modeling (FDM) system; 3D Systems’ (Rock Hill, S.C.) Stereolithography (SLA) platforms; and EnvisionTEC’s (Ferndale, Mich.) Computer Aided Modeling Devices (CAMOD). (For system and materials descriptions, see “The Rise of Rapid Manufacturing” in this issue, p. 32.) Core fabrication by these methods requires no tooling or machining and, therefore, frees engineers to realize an unlimited range of internal reinforcing patterns.Stratasys’ FDM platform uses commercial-grade thermoplastics, such as polycarbonate and ABS. Previously, FDM has been used in the D-DAC manufacturing process to build a number of cores from polycarbonate, because the material provided the desired balance of strength, temperature and heat-transfer properties. FDM also mitigates a general concern about additive fabrication systems: A potential drop-off in mechanical properties compared to injection-molded parts, because the former fabricates parts in layers, at less density than molded parts. Jones says Dynastrosi’s tests show that FDM polycarbonate parts achieve a modulus similar to molded parts in the lengthwise or extruded direction, and between 60 to 80 percent of the modulus of molded parts in the direction perpendicular to extrusion. FDM also fared well in materials characterization studies done on composite cores in 2000. This presently gives FDM an edge over the other systems, according to Jones.

The machines built by 3D Systems and EnvsionTEC both use a variety of photocurable resins. Early on, accelerated aging tests on unfaced composite cores made from 3D Systems’ SLA photopolymers indicated that they lose about 60 percent of their modulus in three years. But Jones points out that SLA-built cores faced with carbon fiber skins and subjected to the same aging tests have suffered no loss in modulus in nine years. He also reports that, since then, 3D Systems has developed more UV-stable materials that have higher modulus. Therefore, FDM and SLA and their respective materials will be evaluated as part of the testing for the prototype turbine blade.

As with more traditional techniques used to manufacture structural composite parts, the trade-off between performance and cost will play a role in the choice of the platform and materials that ultimately will be used to build the blades. Throughput speed figures prominently in the cost side of the equation, and here is where EnvisionTEC’s CAMOD technology offers a distinct advantage. Jones says build time for a given part with EnvisionTEC’s equipment is about 250 percent faster than either FDM or SLA. The difference in throughput speed is accounted for by the way each system builds and cures materials: FDM and SLA machines build layers of a part by tracing out material a scan line at a time, but EnvisionTEC’s CAMOD builds and cures an entire layer at once. Jones says EnvisionTEC has been working to develop stronger, more heat-resistant materials and has agreed to support Wind Sweeper’s research on the wind-turbine blade anti-icing project.

Complex functionality, simpler steps

If polycarbonate and the FDM platform prevail in the testing, Wind Sweeper most likely will use the Stratasys 900mc FDM machine to build the composite core structure of the turbine wing. The first machine made by Stratasys specifically for production parts, it has a build envelope of 36 by 24 by 36 inches (914 by 610 by 914 mm) with ±0.003 inch/±0.076 mm accuracy. Its speed is determined by layer thickness, which can range from 0.013 inch/0.330 mm, for optimum throughput, to 0.007 inch/0.178 mm when surface finish is the priority. The length of the blade requires that the core be divided and built in a series of interlocking sections of equal length. Because each core section will accommodate a section of the integrated heat conduits, the critical concern is that the net-shape core sections mate and interlock properly, with conduit openings perfectly aligned. Because the cores are relatively thin, Jones believes it may be possible to batch-build the cores for all three blades of a complete wind turbine in a single machine cycle, using a nested configuration he likens to “spoons in a drawer.”The core’s cell geometry is yet to be determined. A number of potential cell shapes and sizes are under consideration. But here, Jones argues, conventional core geometries often are dictated by cost rather than performance. “The reason that commercial plastic core materials are almost always some type of hex-cell pattern is that it is relatively inexpensive to extrude,” he claims. “But if you look at patterns overall, the hexagonal cell is not even close to being the strongest per unit of mass.” A leading contender in terms of shape and strength, says Jones, is the tetrahedral truss, an open lattice network of very thin “sticks” of material fused together (see photo, p. 28). Tetrahedral trusses provide about a 30 percent increase in strength-to-weight ratio compared to aramid honeycomb, what many in aerospace, according to Jones, consider the “gold standard” for sandwich core structures. Further, the tetrahedral lattice eliminates the need for conduits, because the open design will be 80 to 90 percent void. Heated air could flow almost unobstructed through the latticework and easily come into contact with the leading edge faceskins.

Tetrahedral trusses, however, take considerably more time to build via additive fabrication. If FDM or SLA materials are selected for the wing, therefore, Jones says they will choose a more traditional closed cell design that incorporates heat-exchange conduits. Tetrahedral trusses will be viable from a cost standpoint only with the faster EnvisionTEC system. Tests are ongoing to determine the best combination of machine technology, materials and core geometry. “We know it’s doable,” says Jones. “We’ve created a whole new art of product design, but we’re really in the infancy of exploring all the possibilities.”

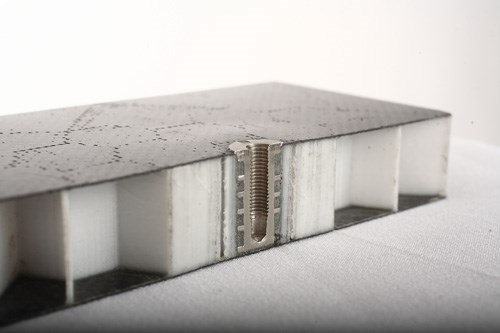

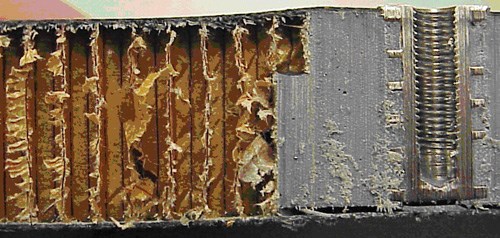

Jones says the turbine blade’s sandwich-composite design plays to the strength of the D-DAC fabrication method. “If you are trying to use commercial-grade core materials in a part like this with compound-curve geometry, which many aerospace and wind energy parts have, you have the cost of a mold or mandrel, then you have the cost of machining and labor operations to rout out conduit and fixtures for attaching the wings to struts.” These added costs and other drawbacks, Jones believes, are part of the reason why the aerospace industry keeps gravitating back to “black aluminum” (carbon fiber skin over carbon fiber ribs) even though sandwich structures have higher strength-to-weight ratios. D-DAC, however, is expected not only to build the pre-curved, net-shaped core and integrated heat-exchanger conduit in a single step but also will provide a means to attach blades to struts without the need for additional finishing operations. Each turbine wing is attached at three points to individual struts. The traditional method of attachment involves a potted insert — drilling a hole through the inside surface of the blade skin, auguring out some of the cell structure, inserting a threaded fixture and then injecting epoxy to encase the insert and fill in the hole. D-DAC saves the time and cost associated with this method because a receiver can be integrated into the core during the additive fabrication process to house the insert. The method provides the additional benefit of eliminating the epoxy fill, saving up to 70 percent in epoxy weight (see the photo comparison on p. 30).

Military and civilian targets

While Wind Sweeper’s line of 1- to 10-kW wind turbines with anti-icing capability is eventually intended for residential and commercial customers located in urban centers, Jones believes early adapters will be remote military bases, including outposts such as early-warning radar stations, most of which are not on a power grid. Diesel generators currently power most of these installations, but U.S. military bases are now under a mandate to reduce their carbon footprint.Given the Obama Administration’s push to fund renewable energy development, these urban turbines could be hitting the wind energy market at an opportune moment in the history of U.S. energy policy development. Wind Sweeper’s efforts to design a small wind turbine that can safely operate unattended, with the added advantage of anti-icing composite blades built cost-effectively on U.S. soil, could give the company a clear shot at dominant “small-wind” market share.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreRead Next

Direct manufacturing of military aircraft parts

Laser sintering process shortens lead time, simplifies production of complex, high-performance parts.

Read MoreThe rise of rapid manufacturing

An outgrowth of rapid prototyping, tool-free additive fabrication technologies have the potential to form small, limited-run composite parts directly from CAD data.

Read MoreCarbon fiber composite driveshaft drives innovative wind turbine

As wind turbine designers try to capture greater energy with each turbine, blade length, size and weight have increased dramatically. Further, blade tip speed is limited by noise ordinances, so very large turbines typically spin at less than 20 rpm. Yet hub rotation is the driver for the generator. For that reason,

Read More