VBO prepregs: The Vision SF50

OOA vacuum-bag-only process makes carbon fiber structures a reality for the world’s first personal jet.

Cirrus Aircraft’s (Duluth, MN, US) Vision SF50, when it enters the market in 2016, will be the newest entrant in general aviation’s personal jet segment. This five-plus passenger, single-engine, V-tailed aircraft is 9.4m long, has a wingspan of 11.7m, a maximum takeoff weight of 2,722 kg and features a maximum cruise speed of 300 KTAS. The piggyback-mounted Williams International engine offers 1,800 lb of thrust and helps put jet-aircraft performance within reach of private flying enthusiasts.

The SF50 airframe features 350 parts — including stabilizer, fuselage and wing structure — manufactured primarily using carbon fiber composites fabricated with out-of-autoclave (OOA) processes that help make this craft mechanically robust and durable.

Tony Snyder, engineering manager of manufacturing operations at Cirrus, says the company chose OOA for the SF50 after it was successfully used to make structures for its SR2X series of piston and propeller-based single-engine personal aircraft. Snyder says of the decision to use OOA processes, “The capital avoidance savings are significant, as well as the reduction in operational costs.” High on the list of the latter is the cost of autoclave nitrogen consumption.

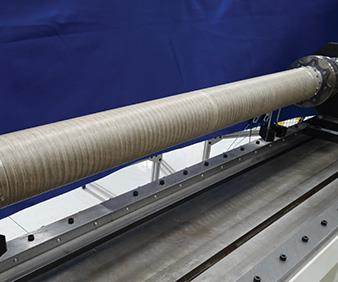

The material used in the SF50 is TC275, a carbon fiber/epoxy prepreg supplied by TenCate Advanced Composites (Morgan Hill, CA, US). It is hand-layed and ranges in thicknesses from 1 mm to 127 mm. Parts are vacuum bagged and then cured in an oven at 135°C for about 10 hours. Thicker parts are run through an additional debulking cycle as well. Ovens are supplied by Gehnrich (now Wisconsin Oven, E. Troy, WI, US) and Rapid Engineering (Comstock Park, MI, US).

Cirrus has done a great deal of process development in order to optimize OOA operations for the myriad parts made, says Eric Olson, materials engineer for airframe engineering. This included development of cure profiles specific to part size, tool type and part geometry, which built flexibility into the system. “Lots of investigation was done to better understand how resin was flowing within the fiber bed during cure,” he says. “This included flow-indicating layers on test parts, image analysis, micro CT and DOEs [designs of experiments]. Much of the trial-and-error work was aimed at quantification of the variables impacting laminate quality and getting a better understanding of resin flow.”

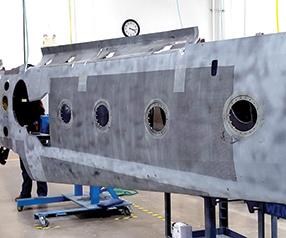

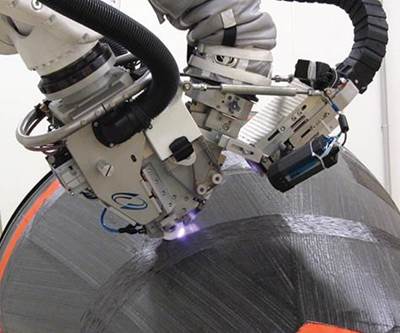

Post-mold finishing, routing and drilling is performed using the company’s 5-axis CNC machine supplied by Diversified Machining Systems (Colorado Springs, CO, US). The fuselage, as the photos show, is fabricated in sections and then assembled via bonding and fasteners. Bonding is done with Huntsman Advanced Materials’ (The Woodlands, TX, US) Epibond two-part structural adhesive.

Many finished parts are assessed via nondestructive testing (NDT) using ultrasonic pulse/echo technology. Larger structures, such as the fuselage, are evaluated by one of two automated ultrasonic inspection systems supplied by Matec Instrument Cos. (Northborough, MA, US). When it comes to quality control, Olson says Cirrus obviously considers porosity, but that’s not the only parameter the company measures. Part criticality, damage tolerance substantiation and inspection methods also factor in, he says.

Cirrus’ ultimate production targets a build rate of 2.5 jets per week, 125 aircraft per year. The Vision SF50 is currently undergoing final flight testing and its FAA certification is expected in the first half of 2016, with customer deliveries beginning shortly thereafter.

Related Content

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MoreMFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreRead Next

Dry fiber placement: Surpassing limits

Coriolis Composites’ automated aerostructures manufacturing using dry materials moves from development projects to production.

Read MoreOOA: Thermoplastic alternative targets performance spec

CF/PEEK helicopter driveshaft’s toughness trumps traditional metric.

Read More