Watersports manufacturer diversifies into new markets, processes

CW Top Shops honoree Cobra International reflects on its growth over 45+ years, as well as current work expanding its automotive and UAV capabilities, increasing energy efficiency and new SMC production lines.

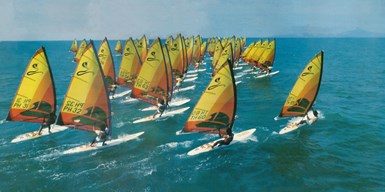

In its 46 years of operation, Cobra International has expanded from a focus on composite windsurf boards to a variety of applications in watersports, automotive, drones and more. Source all images | Cobra International

Cobra International (Chonburi, Thailand), specializing today in composite watersports products, automotive components and more, was originally founded under the name Windglider Thailand in 1978, out of a garage in Bangkok, Thailand, by Vorapant Chotikapanich and brothers Bert and Karl Morsbach.

Danu Chotikapanich, current CEO of Cobra (and Vorapant’s son), explains, “The early days of the company were all about building the finest composite windsurf boards. The Morsbach brothers and my father were passionate about creating Thai-build boards for the second Siam Cup in 1977, and expanding their community of like-minded water lovers by combining lightweight composite manufacturing with their spare-time hobbies.”

The early days were not without “bumps in the road,” Chotikapanich adds, “and it took a massive effort from my father and his partners to keep things running, but around 45 years later, we’re still a watersports company.”

The early days of Windglider Thailand involved construction of windsurf boards by hand out of a garage (top image). The company’s key product became the King Cobra board (bottom image).

The company changed its name in 1985 to Cobra International, for two reasons, Chotikapanich explains: “Partly this was a reference to one of the company’s key products — the King Cobra windsurf board — and of course, it is also a reference to the massive local snake population that lived in the swamp land by the factory.”

The company has changed locations a few times since its humble garage beginnings, and in 2000 moved to the current site near Chonburi. Today, Cobra operates around 100,000 square meters of production space, with a team of about 2,300 total employees.

Over the years, the company’s product portfolio has also expanded beyond watersports, including composite automotive components as a second core market, as well as industrial, architectural and unmanned aerial vehicle (UAV) applications. “But we remain true to our early philosophy — to provide customers with a one-stop shop for serial production of strong, light and beautiful composite components,” Chotikapanich says.

Cobra is one of the honorees for CW Top Shops 2023. Beyond the data, what makes these facilities stand out? The CW team asked each of the latest honorees to share more about their companies’ histories, goals and trends in the composites industry.

The following Q&A features responses from Chotikapanich:

CW: What composite materials and processes do you work with?

Chotikapanich: The range is pretty extensive. We use traditional techniques such as hand lamination techniques used in surfboard manufacturing, and also more advanced processes such as resin transfer molding (RTM) for fins and smaller components, vacuum infusion and press molded or autoclave-cured prepreg manufacturing for a lot of automotive and foil-type components.

In terms of our specialty, I would say that sandwich-type construction, as employed on the very first boards we built, is something Cobra excels at. We’ve been lucky to have worked with many customers in watersports who have let us introduce variants of this technology, and we have also partnered with others to co-develop solutions that have produced lighter, stiffer and more durable boards all featuring sandwich technology.

CW: What end markets do you serve?

Chotikapanich: Over the 40+ years Cobra has been delivering composite solutions, we have certainly touched most end markets. Historically, we have always been strongest in watersports, evolving from windsurfing and then adding surf, SUP, eFoil and kayaks to the mix. Automotive parts became the second “core” Cobra market with CAC (our automotive business unit) joining from 2006 onward. In more recent years, we have seen Cobra diversify into architectural, luxury goods and a wide range of what we call electronic composite products — which is where we group things such as robots, eFoil and urban air mobility parts.

Today, the company’s facility in Chonburi, near Bangkok, features 100,000 square meters of production space. The company’s location is ideally located near the airport and seaports, and in an industrial area with a large workforce of skilled technicians and operators.

CW: Reflecting back on 2023, what was Cobra’s top achievement or strength?

Chotikapanich: In summary, I would say it has been the Cobra team’s adaptability that has impressed me the most in 2023. We’ve had to react to some significant demand shifts from our watersports customers, and the team has really delivered here. We have added additional dedicated resources to handle newer markets such as robotics and drone components, and things seem to be going very well in those areas. We’ve seen two new production areas added to the mix this year, with carbon fiber sheet molding compound (SMC) production starting for automotive, and also the final assembly of eFoil boards being included for a premium customer. This additional service, a one-stop-service for electronic composite products, is creating a lot of interest within the UAV, mobility and eFoil industries.

CW: What goals do you have going into 2024, or what opportunities do you see ahead?

Cobra produces a variety of composite applications at its facility, including watersports and marine applications. The bottom photo shows prepreg layup for windsurf board fins that will be manufactured via resin transfer molding (RTM).

Chotikapanich: Building on what we have already developed in 2023, flexibility will be key again. One thing we know for sure is that the watersports demand will bounce back as inventory issues resolve themselves. What will be critical is to ensure that we’re ready for this uptake, as well as managing the new market demands. We need to ensure that our business processes are smart and enable us to respond quickly, and with adaptability that lets us service the rapid developments and mass customization the watersports market now requires. Some of the new drone and air mobility programs that we’re working on have some build targets that would rapidly see themselves providing a third “core” business unit for Cobra over the next few years, and we want to make that happen.

CW: I know sustainability has always been a major focus of Cobra’s. How does sustainability factor into the company’s operations today?

Chotikapanich: I would say that sustainability is a massive “check point” when we look at any new business option. Whether it is in terms of the product (how we can minimize scrap or use some recycled materials from the start) or the process (can we reuse or modify existing tooling or can we recycle heat generated throughout the process for another purpose).

For current projects, sustainability is a key focus point driven by our own strategy and 2050 goals. Many of our customers operate in markets that require lighter, cleaner vehicles or leisure products that don’t pollute the environment — for them it’s critical that their suppliers are also on the same page. Leading European automotive OEMs continue to push us hard as we develop new flax format parts for automotive markets.

However, sustainability is not just a matter of raw materials; we can also win in terms of product life. We build our products to be strong and durable, and this means we create, for example, boards that last for many years, keeping the materials in use for longer.

Our solar project was a big win in 2023, adding 4,000 kilowatt peak power (kWp) of solar capacity to our own factory roofs. This currently supplies around 40% of our overall electrical needs and this is something we plan to increase in time as we work toward our mission to reach 100% green operations by 2050.

CW: Cobra has also spoken about diversification of your operations, including new processes (like SMC) and markets (like automotive). What are some processes, products or end markets that are new focuses for Cobra, and in what ways is diversification important to Cobra now and moving forward?

Beyond watersports and marine, Cobra has extended its high-quality composites expertise into other end markets, such as drones (pictured).

Chotikapanich: That’s correct, we are currently operating two 500-ton press machines to support SMC parts for our automotive business. We have now started production of carbon fiber SMC components for a large, premium German motorcycle brand for their adventure bike program.

In other markets (mainly in marine parts like foils and UAV components) where high-volume prepreg parts are required, we’ve seen a shift toward press molding of prepreg that can be cycled more quickly than autoclave production.

Finally, we’ve also begun to include more “wetpreg” type production for drones as well as Olympic standard canoes, kayaks and rowing boats where low weight and performance are critical.

Cobra aims to balance the aesthetics and artisanship of making parts by hand with automation and streamlining of certain processes. Pictured here is a robotic sprayer.

CW: Does your facility employ automation, or plan to do so in future? If so, what processes are or will be automated?

Chotikapanich: At Cobra, many of our customers’ products rely on hand finishing processes and Cobra’s ability to, as our slogan says, make composites “Strong, Light and Beautiful,” so there are definitely some elements that will stay as hand work. In other areas — fabric and prepreg cutting, CNC mold and blank production, and molded part trimming, for example — we use the latest in automated cutting tables, robotics and CNC machines to ensure that production isn’t just faster, it’s also more consistent.

Going forwards, in CAC, we are currently looking into automation options for bonding and painting processes, as well as investigating how we can streamline other measurement and QC processes with smart automation solutions.

Related Content

CW Top Shops 2022: Recognizing composites industry leaders

The highest-performing facilities from the 2022 CW Top Shops benchmarking survey share insights about business growth, overcoming labor shortages, sustainability best practices and more.

Read MoreTop Shops Benchmarking Survey FAQs

CompositeWorld’s Top Shops Benchmarking Survey is gearing up for 2025. Gardner Business Intelligence, the research arm of Gardner Business Media, offers some insights for taking the survey and interpreting the results.

Read MoreCW Top Shops 2023: Honoring global top-performing facilities

CW congratulates the 2023 CW Top Shops honorees and composites fabricators whose leaders cite team expansion, focus on Industry 4.0 and adaptation to emerging markets among this year’s top achievements.

Read MoreFiberglass conduit manufacturer grows into new products, infrastructure applications

Texas-based Champion Fiberglass, a five-time CW Top Shops honoree, expands its success in the fiberglass composite conduit market into new applications and products, looking toward future automation and sustainability initiatives.

Read MoreRead Next

Composites end markets: Sports and recreation (2024)

Light weight and high performance continue to make composites popular in the elite sporting good market. Sustainability in both materials and recycling solutions are a key innovation area.

Read MoreCobra, Schmitt Marine collaborate on composite steering wheel for motor yachts

Primus CF wheel is comprised of carbon fiber prepreg skins and an epoxy glass fiber core, offered as a top-of-the-range option for premium vessel owners.

Read MoreFiberglass conduit manufacturer grows into new products, infrastructure applications

Texas-based Champion Fiberglass, a five-time CW Top Shops honoree, expands its success in the fiberglass composite conduit market into new applications and products, looking toward future automation and sustainability initiatives.

Read More

.jpg;width=70;height=70;mode=crop)