CW Blog

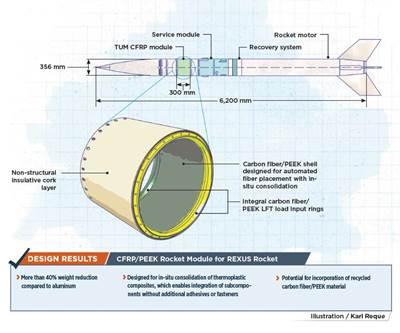

CFRP module saves weight on rocket design

Taking advantage of carbon fiber/PEEK mechanical and thermal performance, the Technical University of Munich replaces an aluminum rocket module with a 40+% lighter composite alternative.

Read MoreFuture automotive is collaborative, digital and smart using composites

According to Swedish startup Uniti, “The era of heavy, costly and unsustainable is coming to an end.”

WatchBio-composites break into structural automotive applications

A company’s bio-based, polyamide composite comes with a unique property profile that may help it carve a niche in automotive applications.

Read MoreCW's top 10 posts of 2018

The top 10 most viewed articles on the CompositesWorld website in 2018.

Read MoreAerospace outlook: A dynamic, evolving supply chain and market

With major new aircraft programs on the horizon, the aerospace industry is looking to reduce costs and increase efficiencies.

Read MoreThe best job I ever had

Retiring CW senior editor Sara Black reflects on her almost twenty years as a writer for CompositesWorld and all she’s learned along the way.

Read MoreReflections on carbon fiber

Highlights from the December 2018 Carbon Fiber conference include industry leader predictions about commoditization of composites, next-generation aircraft and automotive.

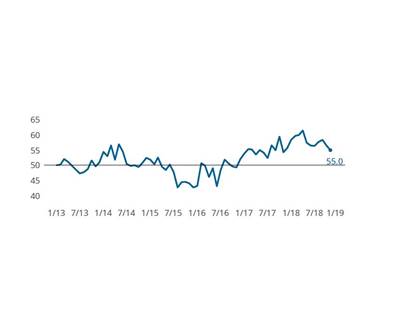

Read MoreIndex expands on supplier deliveries and improved exports

The GBI: Composites Fabricating Index registers a 55.0 reading for November 2018, pulled higher by supplier deliveries and exports.

Read MoreLooking ahead at composites trends in 2019

Columnist Dale Brosius predicts 2019 will reveal growth opportunities in infrastructure, wind energy and personal air mobility for composites.

Read MoreAutocomposites from waste: Garbage in, valuable, functional parts out

Automakers explore use of waste materials to make commercial car parts.

Read MoreDeveloping next-generation composites talent

The M.C. Gill Composites Center at the University of Southern California has steadily grown to become one of the industry’s educational and R&D stalwarts.

WatchComposite radar masts assembled for megayachts

Vabo Composites designs, builds and assembles 10m-tall composite radar masts, improving weight, stability and performance for modern megayachts.

Read More