CW Blog

Passion, persistence and patience – winning the long game

The American Composite Manufacturers Association (ACMA) and others have been pushing for the widespread use of fiber-reinforced polymer (FRP) rebar in infrastructure construction for decades. Now, the industry is starting to see some major wins.

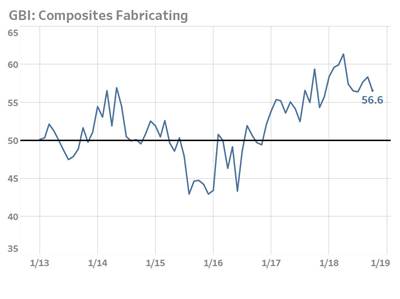

Read MoreComposites Index extends strong expansion trend

The GBI: Composites Fabricating Index continued its expansion trend with a 56.6 reading for October.

Read MoreTo boldly go . . .

In 50 years, how we will look back on this new age of corporation-led space flight?

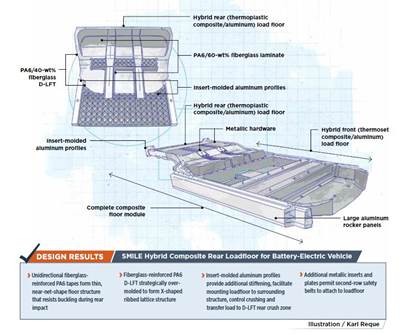

Read MoreHybrid thermoplastics give load floor impact strength

Project leads to development of new compression process for selective application of D-LFT on UD tape laminates.

Read MoreLeveraging composites for space tourism

Virgin Galactic’s WhiteKnightTwo will carry its SpaceShipTwo to launch position, then rocket passengers to suborbital space for a heavenly view of Earth.

Read MoreIACMI Scale-Up Research Facility to host Compression Molding Workshop

Workshop aims to enable OEMs and fabricators seeking to expand composites penetration in automotive and other end markets.

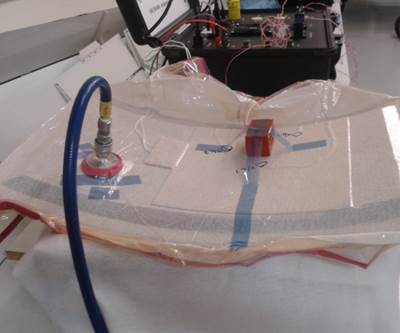

Read MoreMeasuring temperature inside composites and bondlines

ThermoPulse sensors offer Industry 4.0 temperature measurement and digital cure cycle management for bonded composite repairs, laminates and more.

Read MoreBasalt fiber gives prosthetics more “give”

Prosthetics and orthotics often take advantage of composite materials’ strength and durability. Basalt fiber has given manufacturer Coyote Design (Boise, ID, US) a performance edge.

Read MorePlant tour: Composite Resources, Rock Hill, SC

Equipped to meet vertical needs with rapid turnaround, Rock Hill, SC’s Composite Resources has found the sweet spot between prototypers and large composites manufacturers.

Read MoreP2T process positioned for recycling

British company Prodrive Composites (Milton Keynes, UK) recently issued a press release about a process, called P2T (Primary to Tertiary), for manufacturing recyclable composite components that can satisfy future end-of-life requirements without any compromise in performance.

WatchUniversity of MI Solar Car

The project was sponsored by Teijin, which supplied carbon fiber and aramid materials for the vehicle.

WatchBoeing and Thermwood

The Boeing Co. (Chicago, IL, US) and Thermwood Corp. (Dale, IN, US) have employed additive manufacturing technology to produce a large, single-piece tool for the 777X program.

Read More