CW Blog

Episode 4: Pam Schneider and Mike Braley, A&P Technology

Pam Schneider and Mike Braley with A&P Technology talk about how far braiding has come and what’s on the horizon.

ListenAutomated Preforming, Part 3: Quilted Stratum Process

CW’s tour of Cetim and the QSP line which preforms multi-thickness thermoplastic materials in 40-90 seconds for composite parts with cycle times of 1-2 minutes.

WatchCW Talks: The Composites Podcast

CW Talks: The Composites Podcast is officially up and running. With it we will explore the wide world of composites with the people who have, are and will shape the evolution of the industry.

Read MoreCovestro to provide materials to “Sonnenwagen Aachen” team for solar race

The material manufacturer supports the development of a solar-powered electric car with material donations, technical service and as a gold sponsor.

Read More2017 Paris Air Show is good for composites

There is definitely a lot going on this week at the Paris Air Show at Le Bourget airfield. Much of it relates to composites. Here’s a brief rundown.

WatchEpisode 3: Tom Haulik, Hexcel

The third episode of CW Talks: The Composites Podcast features a conversation with Tom Haulik, sales director of carbon fiber at Hexcel.

ListenThermoplastic composite panels deliver affordable housing solutions

Modular construction concept takes composite housing another step forward, offering a wide range of comparably priced housing solutions to builders of all types.

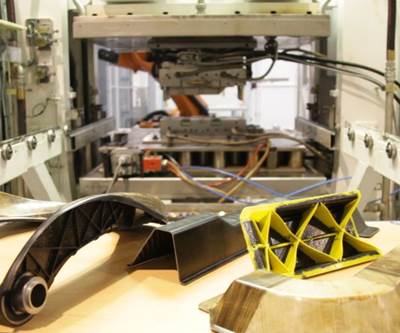

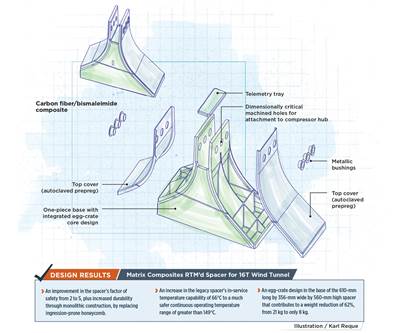

Read MoreRTM-based redesign advances safety for one-of-a-kind wind tunnel

Glass fiber and honeycomb spacers between compressor blades get upgraded to a higher factor of safety with less weight using solid carbon fiber and RTM.

Read MoreA new paradigm in airframe construction?

MTorres, a major supplier of automated manufacturing equipment for composites, has revealed a new way to manufacture airframe structure using composites.

Read MoreNew 3D-printed front air inlet made with Windform composite materials

CRP Technology recently developed a new front air inlet for a Moto3 racing customer, which was manufactured in Windform materials by using an SLS additive manufacturing technique.

Read MoreEpisode 2: Bryan Dods, IACMI

The second episode of CW Talks: The Composites Podcast is an interview with Bryan Dods, CEO of the Institute for Advanced Composites Manufacturing Innovation (IACMI).

ListenEpisode 1: Arnt Offringa, Fokker Technologies, part of GKN Aerospace

The first episode of CW Talks: The Composites Podcast features an interview with Arnt Offringa, head of aerostructures R&T at Fokker Technologies, part of GKN Aerospace, in Hoogeveen, The Netherlands.

Listen