CW Blog

Electric ferry runs quietly with composites

Infused sandwich construction hull and superstructure panels offset battery system weight.

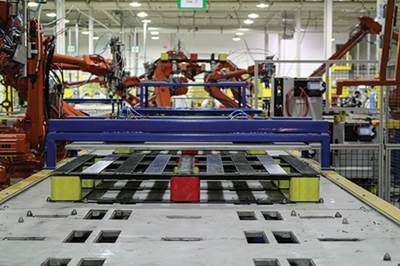

Read MorePultruded polyurethane pallets

Composite solution transforms wooden consumable into profit-generating asset.

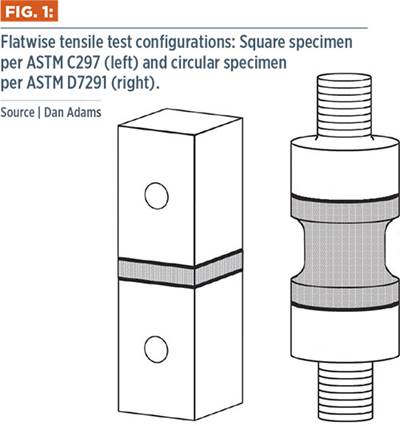

Read MoreMethods for interlaminar tensile testing of composites: A comparative evaluation

Dr. Daniel O. Adams, professor of mechanical engineering and director of the Composite Mechanics Laboratory at the University of Utah and VP of Wyoming Test Fixtures Inc. (Salt Lake City, UT, US) compares and contrasts the direct and indirect loading methods for interlaminar tensile testing of composites.

Read MoreAerospace still matters

CW columnist Dale Brosius is the head of his own consulting company, which serves clients in the composites industry worldwide. Here, he comments on the still prominent role the aerospace industry will have in the automotive industry's integration of composites into its manufacturing mix.

Read MoreNotes from JEC Europe 2015: Known knowns, known unknowns and unknown unknowns

The composites industry’s largest trade show, JEC Europe, was held March 10-12 in Paris. CW's editor-in-chief Jeff Sloan offers his just-back-from-the-show assessment.

Read MoreThermoplastic composites feel the love at NPE2015

At NPE2015, some of the key players involved in thermoplastic composites exhibited a variety of solutions that are leading growth in new and emerging markets.

Read MoreSlideshow of JEC Europe 2015

Another JEC Europe show (March 10-12) has come and gone and CW was there every step of the way reporting on the largest trade show for the industry.

Read MoreKnown knowns, known unknowns, unknown unknowns

JEC Europe 2015, March 10-12 in Paris, shed some light on where composites are, and where they're headed.

Read MoreMaking carbon fiber green

Composite Recycling Technology Center is being established in Washington State.

Read MoreCobham Composites: San Diego, CA, US

An aerocomposites force since the dawn of the 1980s, this fabricator’s Big Idea is to move from quality control to in-situ process control on the strength of metrics powered by Big Data.

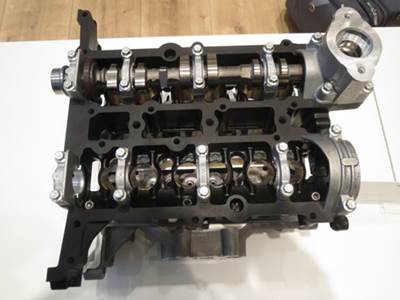

Read MoreAutocomposites Update: Engine oil pans

As thermoplastic composites makes inroads into these complex, modular parts, weight and cost go down, functionality goes up.

Read More