CW Blog

Low-rate layup tools made cost-effective with high-density polyurethane foam blocks

Nemesis Air Racing, an air racing team and kit-plane company owned and operated by Jon and Patricia Sharp, use prebonded closed-cell, polyurethane foam blocks to build the Nemesis NXT.

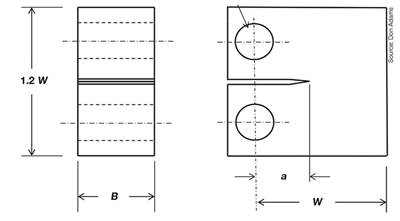

Read MoreCompact tension fracture toughness testing

Dr. Donald A. Adams, president of Wyoming Test Fixtures Inc. (Salt Lake City, Utah) discusses compact tension fracture toughness testing.

Read MoreAerospace and industrial next-gen advanced composites: A two-way street?

The head of his own consulting company and the president of Dayton, Ohio-based Quickstep Composites, the U.S. subsidiary of Australia-based Quickstep Technologies (Bankstown Airport, New South Wales), HPC columnist Dale Brosius sees “aerospace” and “industrial” innovation as a two-way street.

Read MoreAerospace and industrial next-gen advanced composites: A two-way street?

The head of his own consulting company and the president of Dayton, Ohio-based Quickstep Composites, the U.S. subsidiary of Australia-based Quickstep Technologies (Bankstown Airport, New South Wales), HPC columnist Dale Brosius sees “aerospace” and “industrial” innovation as a two-way street.

Read MoreHigh-performance vs. general purpose

Jeff Sloan notes the closing gap between “aerospace” and “industrial” composites.

Read MoreComposites attract (more) attention as construction material

The American Institute of Architects (AIA) is hosting its annual show this week in Chicago, and composites are getting unprecedented attention there.

Read MoreRocTool announces new high-volume molding process

Light Induction Tooling (LIT) combines a simple, low-pressure molding system with fast heating and cooling technology to produce composite parts in cycles ranging from 105 to 310 seconds.

Read MoreCelebrating a great composite design

The well-liked and well-known Hinckley "Picnic Boat" is 20 years old. CW recounts composites use on this popular yacht.

WatchMTI Valve unveiled as innovative solution in resin infusion

New resin inlet valve touted as easy, low-cost way to ensure laminate compaction and “optimal” fiber volume fraction.

WatchWorld's first all-carbon RV

Built without mechanical fasteners and at approximately half the weight of conventional products, the CR-1 is impressive and designed by an impressive team.

WatchORNL demonstrates 3-D printing with carbon fiber

Oak Ridge National Laboratory can print carbon fiber reinforced parts from 10 cm in size up to 2.4m in both lab and production settings at its Carbon Fiber Technology Facility.

Read More