CW Blog

At NAIAS, composites not difficult to find

With CAFE requirements steadily increasing each year, en route to 54.5 mpg by 2025, automakers of all stripes are working composites into new and concept cars.

Read MoreVIDEO: Helicopter Drop Test

NASA evaluates composites’ ability to improve helicopter crashworthiness by dropping a helicopter fuselage to simulate a severe survivable crash according to military and commercial transport requirements.

WatchGKN Aerospace funds new aero-engine composites technology

GKN-led G5Demo project will pursue new composites technologies at Linköping-based ACAB subsidiary, aimed to cut aero-engine CO2-emissions in half by 2020.

WatchBoeing, Airbus neck and neck at end of 2013

Both planemakers set records for orders, deliveries and backlogs in 2013, as the year just ended looks to be one of the healthiest for the commercial aerospace industry in more than 10 years.

Read MoreComposites boon from hydraulic fracturing?

Hydraulic fracturing — commonly known as frac'ing — has become an efficient, if controversial, method for oil and gas extraction. Composite materials are helping pave the way in this very demanding application.

Read MoreCarbon Fiber 2013 report, part 3: Wind energy

Wind and carbon fiber were, at one time, inexorably linked. But that may not be the case — at least for now.

Read MoreBMI and benzoxazine battle for future OOA aerocomposites

Offering weight, cost and process advantages, these “hot zone” resins are moving down the thermometer and into out-of-autoclave structural applications and autoclavable tooling now dominated by epoxies.

Read MoreHigh-speed RTM work cell holds promise for faster part production

Pinette Emidecau Inc. (Troy, Mich.) reports that it has developed an automated, high-speed RTM cell for aerospace and automotive manufacturing applications that is designed to increase molded part throughput and improve process consistency.

Read MoreCarbon stairs make boarding a sailing yacht a breeze

GMT Composites (Bristol, R.I.) makes lightweight but strong — typically carbon fiber — yacht-boarding systems that are easily moved and stowed.

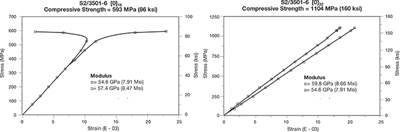

Read MoreBuckling of composite material compression specimens

Dr. Donald F. Adams (Wyoming Test Fixtures, Salt Lake City, Utah) rehearses the causes of, and solutions for, problems with buckling in composite compression specimens.

Read MoreOut-of-autoclave manufacturing: The green solution

Regular HPC columnist Dale Brosius calls attention to the environmental benefits of out-of-autoclave processing.

Read MoreComposites repair

As more composite materials find a place on aircraft, boats, bridges and hundreds of other applications where part replacement is both difficult and expensive, OEM engineers are considering the repairability of structural and secondary composite components during the initial design phase of a project.

Read More