CW Blog

Two visions of 3-D printing in CFRP

Freespace Composites and MarkForged pursue different paths to exploit carbon fiber in 3-D printing.

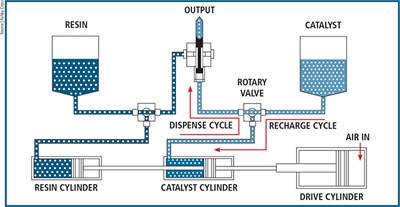

WatchMeter/mix/dispense machines: Doubling down on control

The latest equipment solutions deliver lower costs, faster cycle times and better part properties.

Read MoreFossil and mineral resources: Composites expand

Attention-grabbing applications in these challenging, corrosive environments are positioning fiber-reinforced polymers for continued growth.

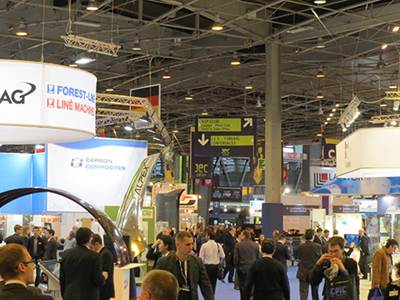

Read MoreJEC Europe 2014 Preview

The composites show’s appearance in Paris this spring promises to be bigger than ever before, reflecting the industry’s post-recession resurgence.

Read MoreComposite leaf springs: Saving weight in production

Fast-reacting resins and speedier processes are making economical volume manufacturing possible.

Read MoreLegacy applications: Inspiration for future vehicles?

Dale Brosius, a consultant and president of Quickstep Composites (Dayton, Ohio), looks back at past automotive composites applications for today's market opportunities.

Read MoreInspection: 30-year-old fiberglass pipeline stands test of time

Examined after three decades in service (half its predicted service life), this filament wound fiberglass pipe showed no signs of degradation.

Read MoreFreefall: Adhesive helps composite lifeboat achieve world record

This composite freefall lifeboat successfully endures the required 65.1m/213.6-ft DNV drop test, setting a new world record for the highest lifeboat freefall.

WatchPipes vs. vessels

CT editor-in-chief Jeff Sloan notes the value of composite pressure vessel standards in the growing market for seawater desalination.

Read MoreLisa Airplanes rises, falls, rises again

Creative use of carbon fiber helped make Lisa Airplanes' Akoya LSA a possibility, and with some fresh financing, it's now on its way to becoming reality.

WatchVestas video documents assembly of world's first 8-MW wind turbine

Wind turbines are getting bigger. Vestas has begun operation of its V164-8.0 MW turbine, with 80m blades, at a Danish test center.

WatchPushing the limits of infusion

Polyworx BV used RTM-Worx, semipermeable membranes, a special feed and vacuum line layout and MMD machines to infuse a 62m minesweeper with degassed resin.

Read More