CW Blog

The outlook for carbon fiber supply and demand

The picture painted at Carbon Fiber 2021 concerning the current supply and demand for carbon fiber indicates an in-flux, rapidly changing environment across a majority of end markets.

Read MorePlant tour: ATC Manufacturing, Post Falls, Idaho, U.S.

ATC is at the top of the list when it comes to thermoplastic composites and aerostructures manufacturing. CW explains why.

Read MoreAll-electric motor boat tests the waters for recycled carbon fiber

RS Sailing aimed to create a fully electric, rigid inflatable boat (RIB) that is produced as sustainably as possible. A few iterations later, the Pulse 63 is ready to hit the water.

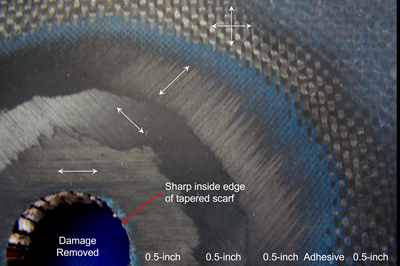

Read MoreA second look at cobonded tapered scarf repairs for composite structures

Composites repairs, such as cobonded tapered scarf repairs, seek to sufficiently restore structural loads so that components perform without failure

Read MoreIn-situ composites sensors for increased production rates, smart processes and life cycle monitoring

Com&Sens FBG sensors are embedded into pressure vessels, rudders and bridges, with new edge and surface connection technology, aimed at cost-effective serial production and monitoring of composite structures.

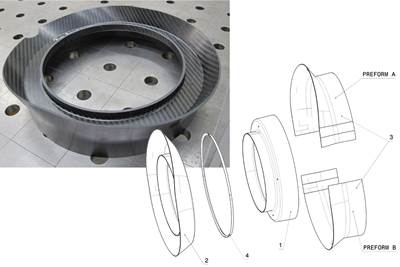

WatchComposite ring frame improves safety, cost for workhorse helicopter

Airbus Helicopters replaces aluminum primary structure with CFRP using multi-piece preform and single-shot infusion.

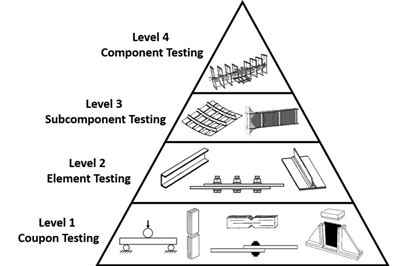

Read MoreComposites testing as part of a building block approach, Part 2: Upper building block levels

Testing under the upper levels of the building block approach for composites design depends on the structure’s application and complexity.

Read MoreThe other composites industry supply chain challenge: Talent

A major topic of discussion during in-person events this year revolved around supply chain disruptions, as well as cultivating new employees. Now, more than ever, it’s important to spread the word on composite industry’s positive collective future.

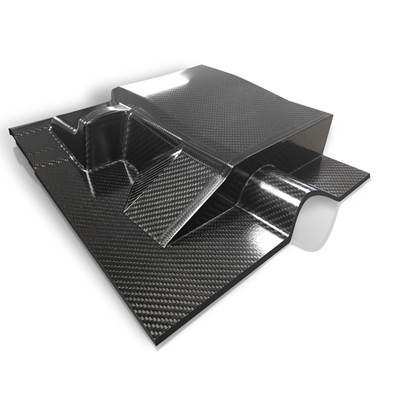

Read MoreComposite tooling as an enabler for next generation adoption of composite materials

Toray Advanced Composites, with new product innovation, is enabling the high performance engineering industries of the future to achieve more efficient, greener designs. (Sponsored)

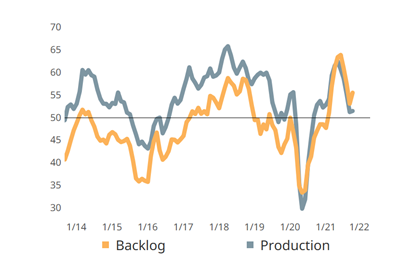

Read MoreBroad-based industry expansion limited by supply chain conditions

October’s readings reflect significant expansion in export orders, new orders, production, employment activity, backlogs and prices received, with a widening “production deficit.”

Read MoreCreating stronger composites through nature-inspired, Helicoid designs

Helicoid Industries claims 50% increased toughness, impact strength and reduced material, weight and cost versus quasi-isotropic “fail-safe” designs.

Read MoreThe compelling argument for expanded use of carbon fiber composites

Contributing columnists from Aramco explain that decreasing carbon fiber prices and continued innovations may allow carbon fiber composites to expand into new markets, including increased use in oil and gas applications.

Read More