CW Blog

Download today's news from CAMX 2021: Thursday, Oct. 21

CW is reporting live from CAMX 2021 this week in Dallas, Texas. Read today’s show headlines covering the ACE Award winners and a host of interesting technologies for the composites industry.

Read MoreDownload today's news from CAMX 2021: Wednesday, Oct. 20

CW is reporting live from CAMX 2021 this week in Dallas, Texas. Read today’s show headlines covering the CAMX Award winners, opening keynote speaker, innovative companies and technologies and more.

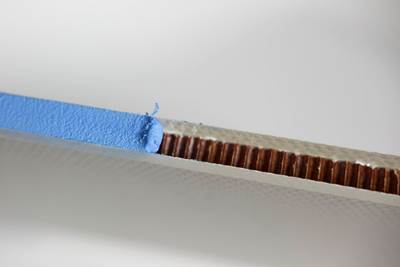

Read MoreL&L Reinforce L-9060: A new approach to fill and reinforce aerospace sandwich panels

L&L Products brings a new approach to fill and reinforce aerospace sandwich panels with L&L Reinforce L-9060. (Sponsored)

WatchHydrogen is poised to fuel composites growth, Part 2

Potential for Type IV composite tanks in H2 refueling stations and distribution, plus targeted cost reductions and emerging technologies for tank recertification and monitoring.

Read MoreDownload today's news from CAMX 2021: Tuesday, Oct. 19

CW is reporting live from CAMX 2021 this week in Dallas, Texas. Read today’s show headlines covering the upcoming keynote speaker, health and safety guidelines, ACE/CAMX award finalists and more.

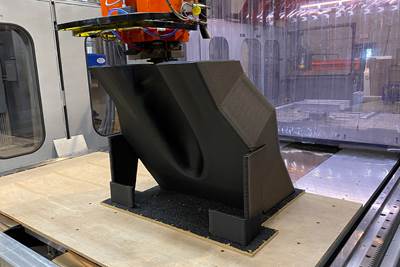

Read MoreCollaborative Boeing-led project validates large-scale composite AM tooling

The U.S. Navy-funded program demonstrated a large-scale, autoclave-curable 3D-printed carbon fiber composite tool using a Thermwood LSAM machine.

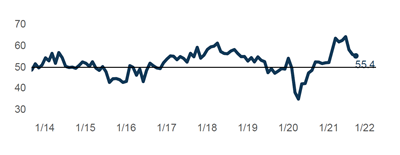

WatchContracting employment and production activity weigh on composites fabricators

Weak employment activity indicated by September readings compounds production supply chain woes.

Read MoreWith CAMX, the composites industry takes a step back toward normal

The symbolism of CAMX is important for an industry and its members who are eager to reconnect on a personal and professional level.

Read MoreThermoplastic composites at Oribi Composites: CW Trending, episode 4

Oribi Composites’ Matt Christensen discusses the origin of the Colorado-based thermoplastic composites fabricator, his role at the company, current products and programs, and the real potential for use of thermoplastic composites in wheels.

WatchCAMX Preview 2021: Introducing Park Place and The Hub

With anticipation ramping up for CAMX 2021, show organizers have unveiled a new destination spot on the show floor designed to better connect those attending the event.

Read MoreCAMX 2021 exhibit preview: Synthene

Synthene promotes a range of its PU resin and elastomer products, including HPE, PRF100, PRA794 and Cristal HRI 35.

Read MoreRefrigerated railcar floor expands composites horizons

TrinityRail, in an effort to update a 20-year-old design, seizes the opportunity to apply composites in a structural application in its refrigerated railcar. It’s a first for the rail and composites industry.

Read More