CW Blog

Plant tour: Bucci Composites, Faenza, Italy

A stalwart in Italy’s “Motor Valley” opens its doors for a discussion and exploration of the company’s history in composites manufacturing for high-performance cars and other applications.

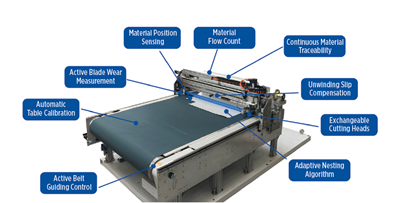

Read MoreModular cutting and stacking system advances flexible, fully automated operations

Integration of next-gen cutting and stacking systems into production lines brings new level of efficiency, quality control.

Read MoreTop 10 CompositesWorld News of 2021

The top 10 most viewed news items on the CompositesWorld website in 2021.

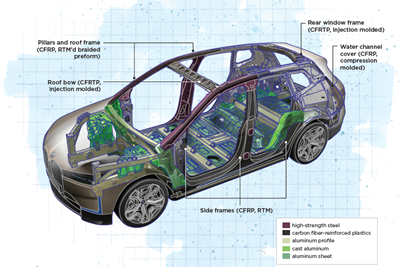

Read MoreBMW rolls out multi-material Carbon Cage with 2022 iX vehicle line

For its new battery-electric iX sports activity vehicle, BMW combines CFRP strategies from previous i3, i8 and 7-Series designs and adds CFRTP for a lightweight, rigid frame.

WatchTop 10 CompositesWorld articles of 2021

As this year comes to a close, CompositesWorld is taking some time to reflect on what the year held for those in the composites industry. Take a look at the most popular articles of 2021.

Read MoreSAMPE’s new CTO, Raj Manchanda: CW Trending Episode 6

SAMPE’s new chief technology officer, Raj Manchanda, talks to CW’s editor-in-chief Jeff Sloan about taking the technical reigns at the composites industry’s most technologically intense organization. Manchanda also talks about his path to SAMPE and the upcoming SAMPE Materials Innovation & Advanced Technology Leadership Forum, Jan. 26-27 in Huntington Beach, Calif., U.S.

WatchCarbon fiber in automotive: At a dead end?

For decades, carbon fiber has failed to break through into mainstream automotive applications as the composites industry has hoped it would. Alternative composite applications suggest future opportunities still remain bright.

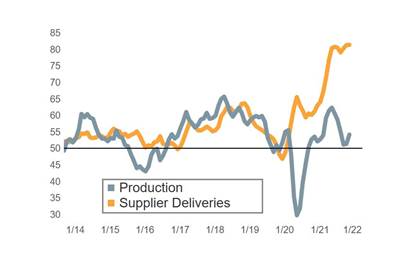

Read MoreEasing supply chain constraints may open production flow

Inflated supplier delivery readings have made a significant decline in November, pointing to a slow, if not steady, improvement in the supply chain.

Read MoreHow ultrasonic testing can find flaws in composite materials

As composite applications expand, so does the demand for more capable inspection systems. Ultrasound has proven to be effective when it comes to in-depth, sophisticated testing.

Read MoreCustomized resin flow mesh products save time, cost for wind turbine blade manufacturers

As longer composite wind blades are developed, customized mesh products help OEMs and kitting companies control resin flow and remove air voids during infusion.

Read MoreConverting from hand layup to open mold spray-up process

In this Digital Demo, Sam Cruz, MVP's Senior Product Manager, talks about how to convert from hand lay-up process to spraying fiberglass and offers an overview of the benefits. (Sponsored)

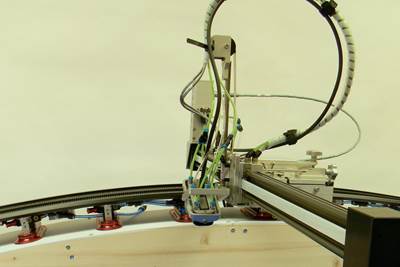

WatchFraunhofer IPT develops thermoplastic composites in hydrogen storage, engine blades and more

Active in laser-assisted tape winding and in-situ consolidation of thermoplastic composites since 1988, the IPT in Aachen, Germany continues to push new materials, applications and Composites 4.0 digital processing.

Watch