CW Blog

Composites end markets: Industrial (2022)

Composites often must meet a certain aesthetic in applications where the consumer is the end user. But fiber-reinforced materials are just as valuable in industrial applications where corrosion resistance, high strength and durability are the performance key.

Read MoreClogging the brain drain: Growing the composites workforce in a pandemic era

As Baby Boomers retire and high school and college graduates forestall their entry into the workforce, composites fabricators need to get creative to close the gap.

Read MoreAdapa Robotic Reconfigurable Mold System at Metyx Booth | CAMX 2021

Adapa’s reusable, adaptive mold system replaces the time and waste of CNC machining and one-off mold production by using the composite part’s digital design file to actuate cylinders which form the system’s silicone membrane surface into curved shapes for molding composites, concrete and glass or thermoforming foam, thermoplastic laminates, etc

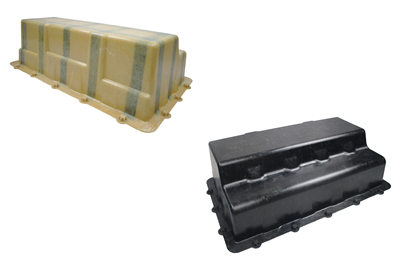

WatchHybrid battery cover: Materials, process decisions

A Q&A with Timo Huber, vice president of HRC’s Advanced Composite Technology Center, discusses material and process considerations for HRC Group’s SMC electric vehicle battery cover research project.

Read MoreEnvisioning high-volume, 100% composite wheels

Vision Wheel debuted its first carbon fiber composite wheel at CAMX 2021, claiming its low-cost, high-volume process can be scaled up for performance vehicles, UTVs and — ultimately — passenger EVs.

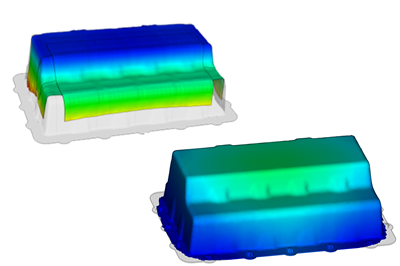

Read MoreHybrid battery cover: CAE approach

A Q&A with Benedikt Fengler, co-founder and composites simulation specialist for Simutence provides a more in-depth take on moldfilling, warpage and assembly simulations performed in HRC Group’s SMC battery cover feasibility study.

Read MoreWhat kind of pickup would Bruce Wayne drive?

Introducing the Brabus 800 Adventure XLP Superblack, a retrofitted Mercedes-AMG G 63 pickup truck that is off-road capable and decked out in carbon fiber.

Read MoreMassivit 3D Digitizes Tooling for Composites Manufacturing | CAMX 2021

Massivit 3D explains its Cast-In-Motion (CIM) technology which uses additive manufacturing and epoxy-based polymers to increase mold production efficiency.

WatchSMC material configurations tailored to automotive battery enclosure design

SMC battery cover offers various module configurations, levels of performance, mass and cost for electric vehicles.

Watch