Exterior of ATC Manufacturing’s 67,000-square-foot purpose-built manufacturing facility in Post Falls, Idaho, U.S. ATC moved here in 2010, soon after Lakeside Capital invested in the company.

Photo Credit: ATC

Thermoplastic composites are, today, among the most talked about materials in the composites industry. They are featured in publications like this one, at conferences and in webinars. Thermoplastics are discussed as much for how they are being applied today as they are for how they might be applied in the future. They span the cost and performance spectrum and have found application in a variety of end markets, from sports and recreation to aerospace. It’s not difficult to understand their appeal. Thermoplastics can be prepregged but are room temperature stable (do not require freezer storage), provide uncommon toughness alongside primary structure mechanicals, do not require an autoclave, offer short cycle times for high-rate production, enable dustless assembly via welding and are reformable and recyclable.

Despite all of these benefits and advantages, and the growing popularity of thermoplastic composites, there are only a handful of fabricators throughout the world that specialize, and even more notably, excel in thermoplastic composites manufacturing. Among these, ATC Manufacturing (Post Falls, Idaho, U.S.) stands out as one of the few companies that offers almost two decades of expertise in rapid forming of 3D parts, larger parts up to 25 feet in length, complex assemblies and thermoplastic continuous compression molding (CCM). CW paid ATC a visit to find out more on what the company does and how it does it.

In the beginning

Like many composites fabricating businesses, ATC Manufacturing started with the vision and passion of one person. In 1990, Dan Jorgenson, at that time an engineer at Boeing in Seattle, helped the company stand up and operate an aircraft interiors manufacturing operation in Spokane, Wash., U.S., in the far eastern part of Washington state. Boeing Spokane focused on the manufacture of interior parts, ducting and flooring, all of which are strong targets for thermoplastics use. In 2003, Boeing sold the Spokane facility to Triumph Group (Berwyn, Pa., U.S.) and it was renamed Triumph Composite Systems. Jorgenson, seeing an opportunity to start his own business, decided to leverage his strong interest in thermoplastic composites and long experience with lean manufacturing principles. So, in 2004 he left Triumph, cashed in his 401(k) investments, took out a second mortgage on his home and founded ATC Manufacturing, which operated for several years out of two facilities, first in Spokane and later in Spokane Valley.

Small, stamp-formed low-load brackets like these were the type of product ATC specialized in when Dan Jorgenson founded the company in 2004. They are still made by ATC today, but as part of a much larger portfolio. Photo Credit: ATC

ATC, in those early days, focused on fast, efficient and cost-effective compression molding of clips, brackets, smoke pans, fire barriers and similar parts using polyetherimide (PEI) and polyphenylene sulfide (PPS) with glass and carbon fiber fabric reinforcement in preconsolidated laminate (organosheet) format. ATC had a variety of customers, but Jorgenson’s history with Boeing made that OEM ATC’s biggest and most important customer.

In 2010, Jorgenson connected with John Hemmingson, founder and general partner of Lakeside Capital Group, also based in Spokane. Lakeside, which has a long history of supporting Spokane-area businesses, eventually invested in ATC and became the company’s largest shareholder. In 2015, ATC relocated to a new purpose-built, 67,000-square-foot manufacturing facility in Post Falls, just across the Washington/Idaho state line and a stone’s throw from Spokane. Jorgenson subsequently retired from ATC in 2019. (In an ironic twist, Lakeside Capital, in July 2021, acquired Triumph’s Spokane facility — the one Jorgenson helped stand up — as Triumph was winding down operations there. Lakeside intends to turn the facility into a manufacturing hub.)

ATC is now managed and led by Hemmingson and Lakeside COO and ATC CEO Jason Kindred. Day-to-day operations at ATC are managed by Derek Downing, director, operations, Jason Merrifield, program manager and David Leach, director, business development.

Once ATC moved into its new facility in Post Falls, the company’s technological capabilities were solidified and strengthened, building the materials and process foundation from which the company continues to innovate and advance. ATC still compression molds many of the types of parts the company started with, but the addition of CCM has expanded its portfolio substantially and established it as a mainstay in thermoplastic aerostructures manufacturing.

In 2014, ATC acquired the first of two continuous compression molding (CCM) lines for the fabrication of multi-ply, multi-angle thermoplastic composite laminates using UD tapes. The second system, parallel to this one, was installed in 2018. Tapes are spooled off the creels (foreground) and fed into the compression die (background). Photo Credit: ATC

The technology

ATC is located in an industrial park in Post Falls, between Spokane in Washington to the west and Coeur d’Alene in Idaho to the east. ATC’s operations are ISO9001, AS9100 and NADCAP certified and include a suite of services including R&D, laminate production via CCM, thermo-stamping, structural metrology, complex assembly, structural NDI and finishing via surface prep, priming, painting and edge sealing.

ATC currently manufactures about 80,000 aerospace parts per month, and these fall into five broad categories: clips and brackets for low-load applications, stiffeners and channels as low- to medium-load connectors, primary structure parts with tight tolerances for high-load applications, long beams in a range of cross sections and assemblies that require additional hardware. One of ATC’s strengths is fabrication of parts using thermoplastic carbon fiber unidirectional (UD) tape materials, which have opened up more structural applications

Much of ATC’s business and growth has been closely tied to Boeing in general and the 787 in particular. Indeed, over the last five years, ATC has been helping Boeing convert many metallic and thermoset composite brackets, stiffeners and other internal structures to thermoplastics in an effort to reduce the risk of galvanic corrosion from metal-on-composite contact, as well as reduce part cost and aircraft weight. ATC has also won production of parts for external aircraft use, including on slats, which are extendable devices on the leading edge of wings that enable takeoff and landing at lower speeds. Almost all of this activity has been fueled, primarily, by the addition at ATC of CCM to produce high-quality thermoplastic laminates and profiles.

In fact, all of ATC’s fabrication operations start with CCM, which has become a major strength of the company. Laminates are built via the CCM process using UD thermoplastic prepregged tapes that are used to make blanks for stamp-forming, and long profiles made directly using the CCM process.

During CW’s visit, ATC was making laminate using 14 plies of a Solvay UD PEEK tape, with 0°, 90° and ±45° orientation. The creels above and below the tapes, at left, are feeding a foil that provides a protective layer as the tapes pass through the compression die.

Photo Credit: ATC

Because thermoplastic composites are thermodynamically and chemically different from thermosets, ATC must use its knowledge and expertise to help educate customers and adjust their designs to best take advantage of the materials and processes that ATC offers. Merrifield, referring to one of the highly contoured parts that ATC produces, notes, “In a project like this, we had to find the balance between what the product can achieve [via complex geometry] against how we can measure and prove the dimensions of that complexity. We often have to come together with the customer on requirements and manage expectations.”

The CCM process, as rare as it is in the composites industry, is remarkably versatile and consistent, allowing ATC to combine a variety of fiber types, fiber formats and resin types to build its laminates and profiles. Laminates are up to 26 inches wide and can be cut to a variety of lengths, depending on the application’s requirements. These laminates are then subsequently employed in one of two applications. The most common is thermo-stamping on one of ATC’s several rapid-heating presses. Alternatively, thermoplastic prepregs can be fed into ATC’s four-axis hydraulic press to be shaped into C, T, H, J, U or similar profiles. These parts, like commercial aircraft beams, can be up to 25 feet long.

Regardless of the application or process, ATC’s manufacturing strategy starts with high-quality, high-throughput laminate fabrication, followed by forming, finishing and inspection processes that enable adherence to strict aerospace standards, including dimensional stability, porosity and fiber volume fraction (FVF). This has made ATC a strong partner to a variety of aerospace OEMs that have come to trust the company’s thermoplastics expertise.

On the floor

CW’s tour of ATC, led by Downing, follows material and process flow and starts where rolls of prepregged carbon fiber/thermoplastic tapes and fabrics are received and prepared. ATC uses tapes supplied by Avient (formerly Gordon Composites, Montrose, Colo., U.S.), Hexcel (Stamford, Conn., U.S.), Solvay Composite Materials (Alpharetta, Ga., U.S.), Teijin Ltd. (Tokyo, Japan) and Toray Advanced Composites (Morgan Hill, Calif., U.S.). Resin types include those most commonly used in aerospace applications — polyetheretherketone (PEEK), polyetherketoneketone (PEKK), polyaryletherketone (PAEK), PPS and PEI — with PEEK and PEKK being the most common.

Preparation involves cutting and slitting of material rolls at 0°, 90° and 45° to enable the assembly of multi-angle, multi-ply laminates. For 0° welds, ATC uses automated butt welding, but 90° and 45° welding must be done by hand. Standard roll length, regardless of angle, is about 150 feet. “One of the challenges at the minute is most of the specs do not allow any overlaps in welding,” Leach says. “By definition, if you run off a creel, you can't have any gaps; the rolls will fall apart if there’s a gap. And you can’t use any extra material, such as backing material holding it together or any extra polymer. So, the plies must be butt-welded, which can be a challenge.”

Tapes are gradually pulled through the consolidation die where they are heated to melt temperature and then cooled to below Tg. The process makes laminate at a rate of about 14 feet per hour. Laminates are cut to 25-foot lengths and then moved to racks for storage prior to NDI.

Photo Credit: ATC

From receiving and material prep we were led to the heart of the facility — the two CCM lines, one installed in 2014 and the other in 2018. They are positioned parallel to each other, each fed by a bank of 70 tape creels. Downing says ATC typically uses some fraction of the total available creels to produce laminates; during the morning of CW’s visit, 18 were in use, loaded with Solvay carbon fiber/PEKK UD tapes in a laminate recipe comprised of 0°/90°/±45° tapes.

The CCM process is fairly straightforward: The creel-fed tapes come together at the end of the creel line, with a layer of foil on top and on bottom. The foil, coated with Frekote mold release from Henkel (Rocky Hill, Conn., U.S.), provides a protective barrier during the compression process and is removed and re-used (multiple times). The 18 plies of tape ATC was processing that day, plus the two layers of foil, once fully stacked, are gradually pulled into a compression die that opens just a fraction of an inch — barely noticeable even to an observer standing at the machine — to allow the tapes to enter before the press closes again. Dies range in width at ATC from 12 to 26 inches. The die running during CW’s visit was 39 inches long and 24 inches wide.

The compression die is divided into five zones. In the first three zones, temperatures for the PEKK running during this visit range from 360-400°C, which is changed according to the melting point of the resin. In the fourth and fifth zones, temperatures start to drop to begin the cooling and promote crystallinity, and by the time the laminate exits the die, it is below the glass transition temperature (Tg). In the case of the PEKK, the Tg is 159°C; ATC targets 130°C for the laminate temperature as it exits the die. “The third zone is set to be cooler,” Leach says. “So the material actually already starts to cool down as it comes through the third zone, and then crystallizes in the fourth zone. DSC [differential scanning calorimetry] tells us at what temperature crystallization is occurring, so you want to make sure the material spends adequate time in the crystallization zone to reach sufficient mechanical properties.”

Cycle times for each closure of the press vary depending on laminate recipe, but Downing says 15 seconds is the norm. With each opening of the press, the laminate is pulled forward about an inch at a time. Downing notes that although the cycle time and advancement speed imply a slow process, ATC has found it to be highly reliable, consistent and efficient.

The laminate, as it emerges from the die, is fully consolidated. Here, the foil is separated and the laminate is, eventually, cut to length depending on product type, and transferred to metal racks adjacent to the CCM lines for cooling. Typical laminate length is about 25 feet.

Each laminate goes through non-destructive inspection (NDI) in this bespoke Marietta NDT pulse echo/thru-transmission ultrasound (TTU) test bed. ATC has tuned its NDI system for thermoplastics, which exhibit different attenuation properties than thermoset materials. Photo Credit: ATC

Next stop, after the CCM line, is non-destructive inspection (NDI) and waterjet cutting. NDI is performed in a 30-foot bespoke water bed manufactured by Marietta NDT (Marietta, Ga., U.S.). It provides simultaneous pulse-echo and thru-transmission ultrasonic (TTU) scanning of each laminate. Scan results are displayed on a long computer monitor at the end of the bed, with comparison against “standard” reference laminates.

Merrifield says ATC learned early on that NDI of thermoplastic laminates requires different settings than those used for thermoset laminates, mainly to adjust for the different attenuation of thermoplastics. Indeed, initial scans with the Marietta system appeared to show anomalies that were, in fact, not present. “There are slight differences in the resin itself that NDI is going to pick up,” Merrifield says. “So, a lot of what went into this was looking at the scan and, if there were anomalies, cutting that part up and looking at it through the microscope to see if there really is a problem. We got a lot of false positives. So, it’s about controlling the NDI to make sure you are looking at what you care about.” Pointing to the monitor, Merrifield adds, “We set up our scans such that if [a value] drops below a certain point, then it’s going to show up as a different color. It helps us easily detect an anomaly.”

This CCM system at ATC features a four-axis die that allows the fabrication of complex C, T, H, J and U profiles that are often applied as load-bearing beams in aircraft interiors. Multi-axis CCM is a complex but efficient and consistent manufacturing process. Photo Credit: ATC

After NDI, many laminates are cut to shape on ATC’s OMAX (Kent, Wash., U.S.) waterjet cutter. Next, after all of the exposure to water via NDI and waterjet cutting, laminates spend 12-16 hours in a drying oven as preparation for the next step in the manufacturing process.

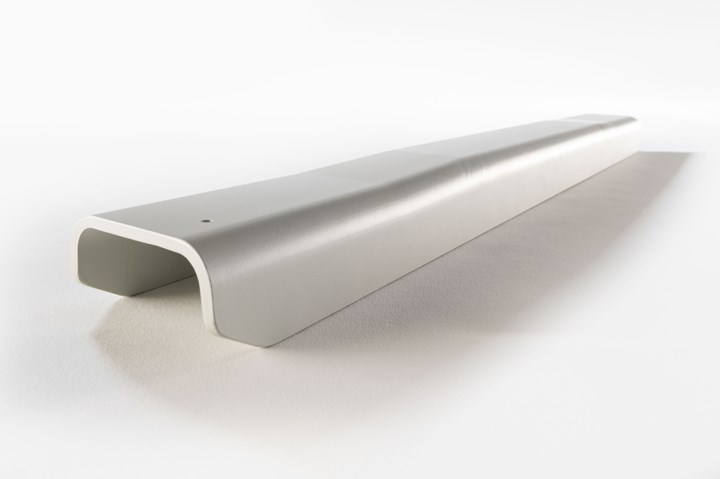

Before heading to the stamp-forming area, we are led briefly to another system that is rarely seen in composites manufacturing. It’s a four-axis CCM profile machine, fed by the same creel-based system as the other CCM machines, but designed to fabricate the complex profiles used to make the C, T, H, J and U beams referenced earlier. “Obviously, the big difference is, instead of having just one set of hydraulic actuators going one way, you’ve got ones going two ways, and then a four-piece die that goes into that to form a part,” Leach notes. “Our profile will take a die set up to 12 inches by 8 inches. So that’s basically the biggest size of profile we could make, which is pretty big for most applications.”

Downing says the learning curve for ATC on this system was substantial because of the complexity of tooling and process control in a multi-axis environment. Material springiness differences in each axes were a particular challenge, but he says those were solved and the company is very comfortable with the system now. The CCM profile system was not operational during CW’s visit; the profiles made by the machine are mostly for commercial aircraft and reduced aerospace production rates have reduced demand for parts.

Blanks are cut from the laminates made via CCM and then transferred to ATC’s foundational process capability, stamp-forming, performed in one of the company’s 10 presses. Stamp-forming of thermoplastic composites requires careful, robust and consistent process control to make sure the resin achieves full crystallinity. ATC uses in-mold thermocouples to measure and control mold temperature. Photo Credit: ATC

The focus of most of the activity at ATC is in the stamp-forming area, where cut laminates take on their ultimate shape. Downing notes that much of the original innovation and intellectual property developed by Jorgenson is in the company’s stamp-forming technology. “Dan had a bit of a different philosophy from the beginning,” Leach says. “The automation looks simpler, but it's appropriate to what you need. So it’ll feed the blank into the oven, and then feed it to the stamp-forming station. But we don’t have big robots doing the work. It’s just an automated handling system.”

ATC currently operates four 80-ton presses and four 30-ton presses, with a single operator managing multiple presses. Each press features an infrared heater that brings blanks quickly up to melt temperature, and a quick-change system to shuttle heated blanks into the mold. The 80-ton presses shuttle preheated blanks into the mold automatically; the 30-ton presses require manual actuation to transfer blanks into the mold. Thermocouples located throughout each mold help monitor the process and provide critical performance data. Cycle time for each part varies, depending on the material, size and thickness, but generally ranges from a few minutes to as long as 20 minutes. All parts are cooled quickly, but in a controlled and prescribed fashion so as to achieve full resin crystallinity and corresponding mechanical properties.

Downing says each machine is controlled with the same off-the-shelf software, with an interface custom-designed for ATC. He notes that ATC spends a great deal of time and effort developing process recipes for each part it produces, but once that recipe is set, “it’s highly consistent and controllable.” Further, notes Merrifield, “If a process does start drifting out, you can see it happen. The system won’t press another part. So, if you know a part is going to be bad, the operator can stop the press and determine the problem.”

Leach notes that managing thermoplastics processing requires a deep understanding of how resins respond to temperature over time. “You want to make sure that you are fully melting the material and that you have a minimum time in the melt zone,” he says. “But you don’t want to exceed 400°C [for PEKK]. You could shorten the heating time and use a very high-temperature oven, for example. But the part temperature can shoot through the acceptable temperature zone. On the other hand, if you set it too low, it might take too long to get to temperature. Both of these scenarios would produce unacceptable parts. We pay very close attention to these things to ensure we make consistent parts, and thermocouples are critical to that.” And it appears to be paying off. Downing says ATC’s strong process control is a big reason why the scrap rate for stamp-forming is <3%.

One time-saving technology ATC has developed for stamp-forming is hot die changes. The company created a die pre-heater that allows it to bring a die up to temperature before it goes in the press, which enables a faster die change-out and quick return to production. “It used to be painful,” Merrifield says, “because change-out of cold dies used to take four or five hours. Now, we have pre-heat stations and we can be pressing within five minutes of a change. Anytime you’re not running, you’re not making money.”

This new 200-ton stamp-forming machine expands ATC’s capabilties beyond the 80- and 30-ton presses already in operation. Photo Credit: ATC

Adjacent to the stamp-forming area are two additional presses — each notable for their age. The first is a new 200-ton unit that ATC was in the process of qualifying for production. The other press was more notable, primarily because it was the first machine Jorgenson built when ATC was founded. It’s a 150-ton system with a 60 x 30-inch platen that, Downing says, “has been upgraded many times.” It’s used mostly for R&D purposes today, and occasionally to supplement primary production.

As we leave the stamp-forming area, Downing, reflecting on Jorgenson’s original press, comments on another legacy of the company's founder: “I think you’ll notice that we run a very clean shop,” he says. “People always comment that we invest in cleaning processes and taking the time to clean. We take foreign object debris [FOD] control very seriously. Dan [Jorgenson] was always a big one for cleaning. Every Thursday, we would stop and close up for an hour or two to clean. We still invest in that culture and it’s something that our team takes pride in.”

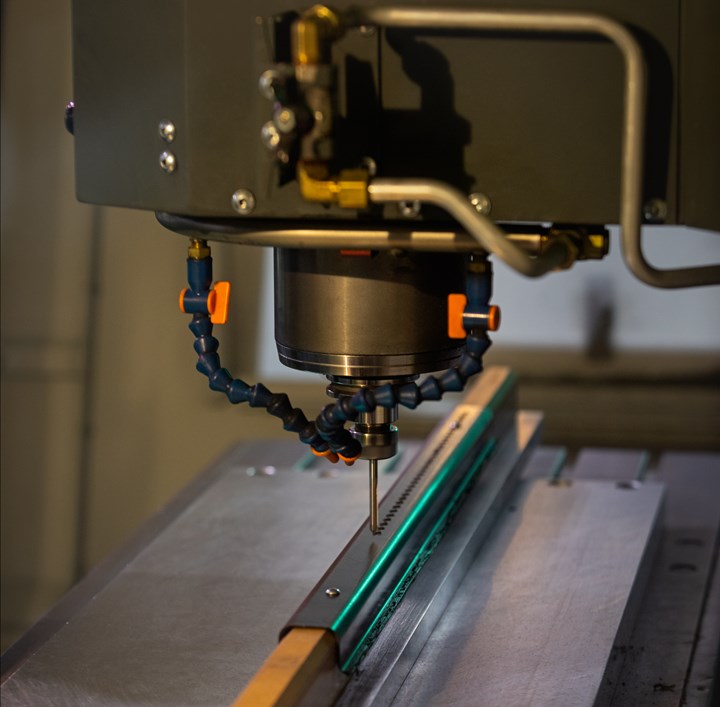

Post-processing

After stamp-forming, we are led through a series of post-process work areas. First is CNC machining, where ATC operates nine Haas Automation (Oxnard, Calif., U.S.) systems and one C.R. Onsrud (Troutman, N.C., U.S.) machine; the Onsrud system is a gantry machine and the largest, with a 12 x 5-foot work area. This system, during CW’s visit, was drilling and countersinking holes on a molded part.

Adjacent to the CNC area is a second NDI work area with a smaller (15-foot) Marietta NDT echo/TTU bed, used to assess smaller parts and to provide redundancy with the larger NDI system near the CCM machines. It’s also used, as it was during CW’s visit, to “teach” the system to scan a new part that is entering production. Also adjacent to the CNC area is a small roll-forming station where ATC produces glass/PPS tubes up to 60 inches long and 1 inch in diameter, with centerless grinding for finishing.

ATC’s CNC operations include nine Haas and one C.R. Onsrud machine, used to trim and drill molded parts. Photo Credit: ATC

Like most composites manufacturing operations, lab and metrology work at ATC is done in enclosed, climate-controlled rooms off the main production floor. The lab features a Tinius Olsen Testing Machine (Horsham, Pa., U.S.) tester, a DSC machine, potting and encapsulation equipment for microscopy, a grit blaster and a tumbler. In metrology, the centerpiece is a Zeiss Industrial Metrology (Maple Grove, Minn., U.S.) metrology table, which provides the high-accuracy dimensional scanning that aerospace manufacturers need. But there is a second tool that sees much use at ATC — a Creaform (Lévis, Quebec, Canada) MetraSCAN 3D handheld scanner. To use it, ATC mounts a part in a fixture and then scans it with the MetraSCAN 3D scanner. Scanning takes about 20 minutes and produces about 1 million data points. It’s fully portable and can be used throughout the facility to inspect dies and molds as well. Downing says the MetraSCAN system, with an accuracy of ±0.0015 inch, is not as accurate as the Zeiss system, “but its speed, cost, portability and flexibility are hard to beat.” ATC acquired the MetraSCAN 3D scanner in 2018 and that year received approval from Boeing to use it to check dimensional tolerance of Boeing production parts. Downing says ATC’s product quality rate and on-time performance is >99%.

Our tour finishes in paint prep and the paint room. Paint prep is done with solvent wipes, using highly detailed and specific protocols, including solvent type, wipe direction and adhesion test for each part. Painting is done in one of two booths, the larger of which is 30 feet long. Protocols are paramount here as well, governing paint coat count, drying times and adhesion requirements. If paint adhesion fails, the paint is (carefully) stripped and the entire prep and paint process is restarted.

Governing the entire workflow at ATC is an electronic manufacturing system that provides paperless instructions at each workstation. Every part has a mark, which is logged into the system by the operator at each station to track its progress throughout the facility. The lack of paper travelers, says Downing, has helped reduce FOD in the plant.

The variety of clips, brackets and stiffeners manufactured by ATC has grown substantially and are used increasingly in commercial aircraft. The durability, toughness and ease of forming make thermoplastics an attractive option inside and outside aircraft. Photo Credit: ATC

Looking ahead

ATC’s strong relationship with Boeing, particularly on the 787 program, fueled much growth at the company over the last decade. ATC is a member of Boeing’s Premier Bidder Program and has twice been nominated for Boeing’s Supplier of the Year Award. In 2019, at the peak of global commercial aerospace production, ATC manufactured more than 1.1 million parts. With the onset of the coronavirus pandemic and reductions in aircraft manufacturing, ATC’s production has understandably dropped, to just less than 1 million parts per annum.

Still, the company is looking avidly to the future, leveraging internal R&D and cooperative R&D to identify new opportunities. ATC, for example, is a member of the ThermoPlastic Composites Research Center (TPRC, Enschede, Netherlands) and has participated in technology development programs with 12 organizations over the last 18 months, including the Defense Advanced Research Projects Agency (DARPA, Arlington, Va., U.S.), the Air Force Research Lab (AFRL, Wright-Patterson Air Force Base, Ohio, U.S.), NASA (Washington, D.C., U.S.) and material suppliers. ATC uses AniForm (Enschede, Netherlands) processing modeling software, which it has supplemented with its own in-house-developed tools to help it achieve even better dimensional control in finished parts.

There is also much work being done at ATC and with industry partners to evaluate technologies that might enable further growth. This includes automated ply preparation for non-rectangular parts and to incorporate ply drops and build-ups, tow steering in automated fiber placement (AFP), larger (10-foot) stamp-formed parts, thermoplastic welding without use of a susceptor, injection overmolding, use of recycled composites and more complex profiles.

Also, like many manufacturers, ATC is concerned about developing a stable supply of actual and potential employees. Internally, it’s using cross-training to maximize employee flexibility. Externally, ATC is working on workforce and training programs with North Idaho College (Coeur d’Alene), Gonzaga University (Spokane) and the University of Idaho (Moscow).

Load-bearing aircraft beams like this one are produced via ATC’s four-axis CCM machine, which enables the manufacture of complex C, T, H, J and U profiles. Photo Credit: ATC

Looking ahead, Leach is cautiously optimistic. ATC is looking forward — as are others in the aerospace composites supply chain — to commercial aerospace production returning to pre-pandemic rates. ATC is actively developing other aerospace applications including for advanced air mobility (AAM), unmanned aircraft, defense and launch vehicles. When these markets develop, ATC likely will need to expand, which it has the room for in Post Falls.

“We are already approved to add another 50,000 to 52,000 square feet of space when we needed,” Leach says. “And then on the north side of this building, Lakeside owns five acres, with plenty of room for expansion. The main reason for any expansion, however, would be so that we can make bigger parts with larger scale process equipment technology. We don’t have a problem with capacity within the current facility and the current technology. But bigger parts will require a bigger ATC. We are looking forward to a rapid expansion in thermoplastic applications in the next few years”

Related Content

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More