CW Blog

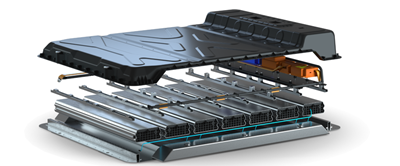

Evonik-led group targets epoxy SMC for EV battery housings

Epoxy modified with an amine-based hardener is applied in a demonstrator EV battery housing. The result is a thermally and mechanically robust structure that offers scalability in a variety of e-mobility applications.

Read MoreAdvanced engineering thermoplastic adhesive hybrid resin

In this Digital Demo, L&L Products introduces T-Link, a new hybrid thermoplastic resin system, that does not require refrigeration or special handling and – being highly customizable – can be easily and quickly consolidated into a composite structure.

WatchEpisode 38: Alan Hiken, Kane Robotics

Alan Hiken, COO of Kane Robotics, talks about historic, current and future composites use in aircraft fuselage structures and the role of automation in next-gen manufacturing environments.

ListenVirtek Iris ActiveTrack: Bring laser projection mobility to your tool

New Unmatched Laser Solution to aid in Streamlining Component Assembly Processes Now precise positioning guidance on mobile tools is possible with Virtek's newest software, IRIS™ ActiveTrack.

WatchAssessing a composites supply chain in flux

The global pandemic, shipping woes and winter storms have wreaked havoc on the composites supply chain. CW attempts to find out how widespread the problem is.

Read MoreThe hydrogen economy: Hope or hype?

Green hydrogen technologies have become the forefront for the global zero-carbon energy landscape. Now, it may be cost that ultimately determines its expansion opportunities into the composites industry.

Read MoreComposite testing challenges, Part 1: Introduction to mechanical testing of composites

A range of standardized mechanical tests for complex composites are available and still under development for materials development, design and quality control requirements.

Read MoreIncreasing demand for composite driveshafts leads to automated production

California-based fabricator ACPT Inc. worked with machine suppliers to build an innovative semi-automated production line featuring an automated filament winder.

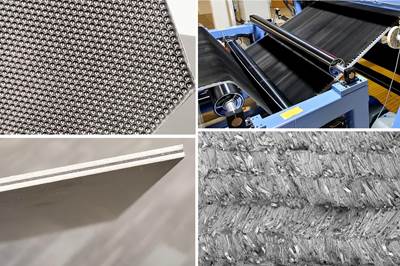

Read MoreZ-direction composite properties on an affordable, industrial scale

Boston Materials uses milled reclaimed carbon fibers to increase modulus, impact/delamination resistance and produce metals-like conductivity for EMI shielding, lightning strike protection, heat exchangers and more.

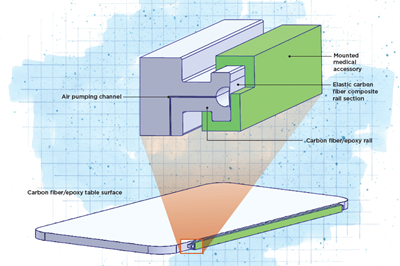

WatchDesign innovations improve efficiency of composite medical table

WIT-Composites' efforts to design a more effective all-composite surgical table led to development of complex components and an elastic carbon fiber material.

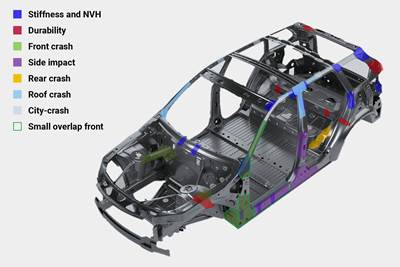

Read MoreComposites as auto-body reinforcements

Hybrid structural-reinforcement technology expands options, gains applications, markets.

Read MoreEpisode 37: Ian Wilson, DASIS

Ian Wilson, CEO of Develop and Supply In-Sync (DASIS), talks about his history as a CNC specialist for Formula One and his introduction to composites manufacturing.

Listen