CW Blog

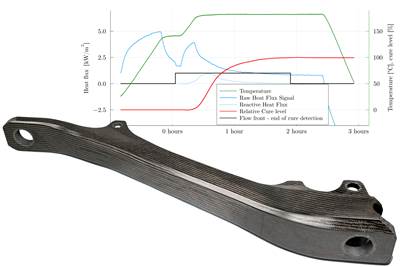

Speeding RTM with heat-flux sensors

Clean Sky 2 INNOTOOL 4.0 project advances cure monitoring for larger and less costly lightweight landing gear made using composites.

Read MoreRocket engine thrust frame proves a strong candidate for composites conversion

The engine thrust frame of a space launch vehicle, located at the bottom of a rocket stage, joining fuel tanks to engines, must deliver strength and stiffness across a range of temperatures — cost-effectively.

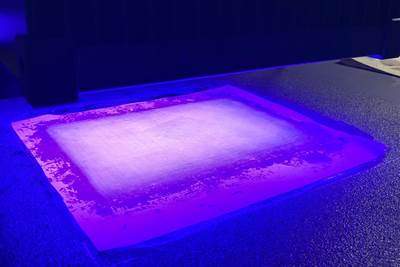

Read MoreEasy-to-use kits enable infield repair of composite structures

Portable kit enables patch repairs using UV-cure glass fiber/vinyl ester or room-temp stored carbon fiber/epoxy prepregs and battery-powered curing equipment.

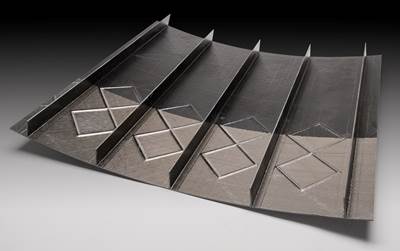

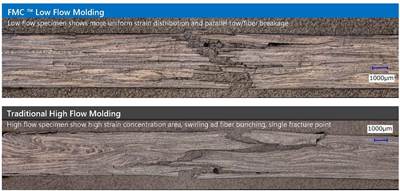

Read MoreForged molding compound: Extending SMC capabilities

New material, design, process combination approaches prepreg performance with chopped carbon fiber SMC.

Read MoreComposite testing challenges, Part 3: Testing systems

Several factors need to be considered for accurate and efficient composites testing, including testing systems that can accommodate required test environments, alignment and offer intuitive software.

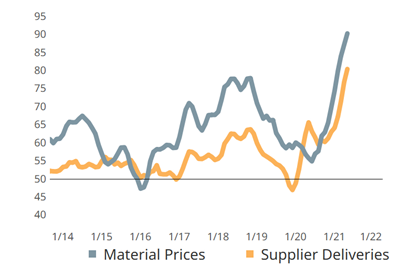

Read MoreComposites Index sustains a third month in record territory

Accelerating new orders, backlogs and challenging supply chains propel the index higher for the month of May.

Read MoreRobotic injection molding for functionalized composites

Anybrid enables compact, flexible hybrid injection molding/overmolding for smaller series and larger components.

WatchHow to: Getting the most from your mold release

Mold release specialist AXEL Plastics offers dos and don’ts for cleaning, stripping and preparing molds for composites manufacturing. (Sponsored)

WatchEpisode 39: Joe Fox, FX Consulting

Consultant Joe Fox talks about the massive potential for composites use in infrastructure applications and what it will take to turn that potential into reality.

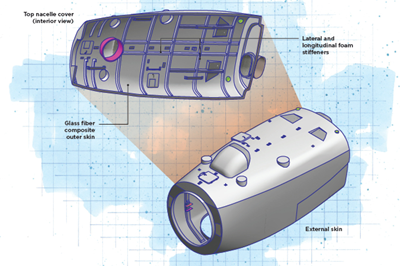

ListenOptimizing a wind turbine nacelle cover to meet LCOE demand

Suzlon Group redesigned a composite nacelle cover with in-situ molded stiffeners to reduce manufacturing and material costs while maximizing part performance.

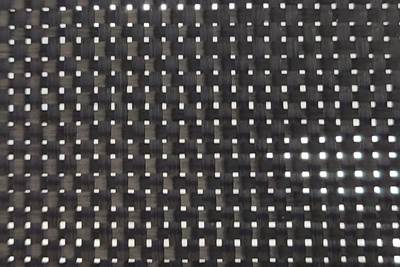

Read MorePorosity, voids and bridging in prepreg autoclave and vacuum bag-only laminates

Consideration of materials, methods and systems explores ways to reduce potential surface porosity, voids, resin-rich areas, bridging and other flaws in composite laminates.

Read MoreDesigning a versatile, multi-material EV battery enclosure

Continental Structural Plastics has developed one-piece, compression-molded composite covers, an innovative fastening system and a range of material options to meet OEM needs.

Read More