CW Blog

Applying UV-curable powder coatings to composites

Keyland Polymer UV Powder reviews the features, benefits and applications of its UV-curable powder coatings in a composites manufacturing environment.

WatchReprocessable, repairable and recyclable epoxy resins for composites

CIDETEC matures 3R resins for aerospace applications via AIRPOXY program.

WatchWhy choose LSAM for large-format additive manufacturing?

Thermwood explores the features of LSAM, it’s large-format additive manufacturing system, including a product line summary, slicing software. (Sponsored)

WatchLarge-scale, robotic-mounted 3D printer aims to expand AM size limits

Italy-based Caracol has developed an extrusion-based, robot-mounted 3D printer to scale up printing capabilities for high-performance aerospace tooling and industrial parts.

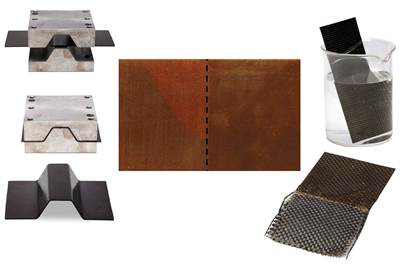

Read MoreComposite thermal breaks boost window insulation value

The composite insulation systems used in windows to insulate building interiors, while rarely seen, are vital to sustainable and efficient residential and commercial construction.

Read MoreLaser projection system optimizes rotor blade manufacture

A series of systems installed by Z-Laser GmbH helped Nordex Group optimize fiber layup and positioning processes during the development of its 74-meter-long wind turbine blade.

Read MoreComposite testing challenges, Part 2: Strain measurement for the mechanical testing of composites

Recent developments in contact and noncontact strain measurement methods offer similar performance with additional benefits for composite material testing.

Read MoreBraided preforms and resin infusion for next-generation aerocomposites

Spintech shows significant cost and labor savings using its Smart Tooling, dry fiber preforms and RTM/VARTM technology on aircraft wing and inlet duct demonstrators.

WatchSTELIA Aerospace Composites advances hydrogen storage

STELIA Aerospace subsidiary converts aero experience into industry-leading storage efficiency for fuel cell applications.

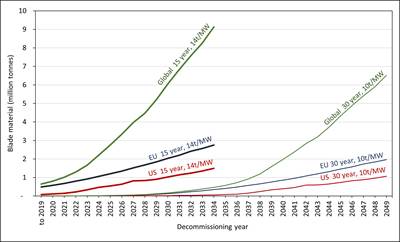

Read MoreDefining the landscape for wind blades at the end of service life

There is a generation of wind turbine blades at or near the end of their useful life. Disposing of them, recycling them or reusing them requires a better understanding of the blade end-of-life landscape.

Read MoreMAMBO tests the waters for 3D printing large marine structures

With its MAMBO boat, Moi Composites demonstrates use of its continuous fiber 3D printing technology for customized, automated production for the boating industry.

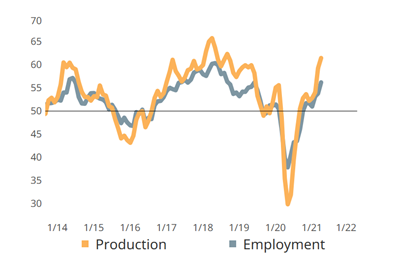

Read MoreComposites index moderates lower after all-time high

Composite fabricators report slowing expansion in new orders, production, with gains made in supplier delivery and employment activity readings.

Read More