CW Blog

The evolution of the commercial aerospace landscape

Following the grounding of the 737 and the downturn caused by the pandemic, Boeing finds itself a distant second to Airbus. What should it do?

Read MoreCommercializing UV-curable thermosets for continuous fiber 3D printing

Strategic partners Continuous Composites and Arkema/Sartomer are developing a library of photocurable resins for use in a variety of OOA, high-speed, high-performance composite applications.

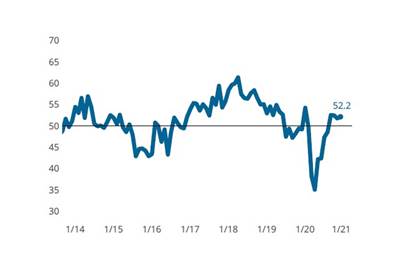

Read MoreSupply chains will mean everything for composites in early 2021

Lengthening order-to-fulfillment times caused the reading for supplier deliveries to surge, lifting the overall December Composites Index into expansionary territory.

Read MoreAdditive Molding technology revolutionizes autonomous drone design

Arris’ Additive Molding process uses consolidated glass/carbon fiber airframe to optimize performance and reduce costs to produce Skydio X2 drone for industrial, consumer and defense use.

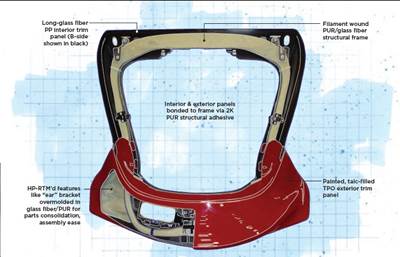

Read MoreLiftgate design puts modified filament winding to the test

Heavily modified winding process produces light, structural support frame for performance-critical liftgate.

Read MoreTow steering, Part 2: The next generation

Wings on next-generation commercial aircraft will be longer, thinner, more aerodynamic and more efficient. They also are ideal candidates for the application of steered tows. One project aimed to design, fabricate and quantify a tow-steered wing skin.

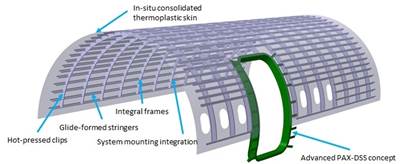

Read MoreManufacturing the upper half of the Multifunctional Fuselage Demonstrator (MFFD)

Proving industrial reliability for low-cost thermoplastic composites production using AFP in-situ consolidation, as well as continuous ultrasonic and resistance welding.

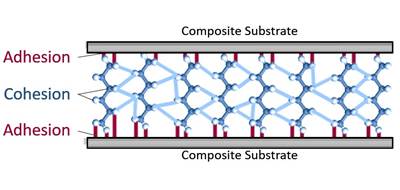

WatchTroubleshooting failures in adhesive-bonded composite joints

Cause of adhesive bonding inconsistencies or failure may be numerous. According to Louis Dorworth, the following points should be examined to determine the culprit.

Read MoreEpisode 36: Dale Brosius and Uday Vaidya, IACMI

IACMI’s Dale Brosius and Uday Vaidya talk about the first five years of the organization, how it has evolved and what the future might hold as IACMI continues its quest to help drive composite materials and process growth.

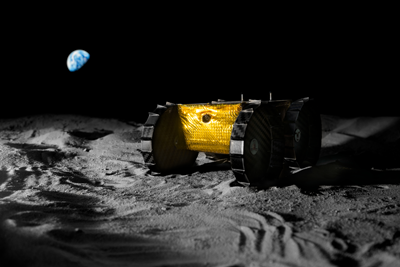

ListenComposites design helps nano-sized lunar rover hit big milestones

Developed by Carnegie Mellon University, the ultralight, composites-intensive Iris nano-rover will make its lunar debut later this year.

Read MoreAll-composite white cane improves mobility for visually impaired

The light weight, ergonomics and stiffness provided by the carbon fiber composite design enable a safer, easier to handle mobility solution.

Read MoreCase History: Scout’s 420 LXF made possible with Vectorply’s Road to Optimization

With a list of must-meet goals in hand, Scout Boats, Inc. turned to Vectorply to assist with laminate design and technical recommendations as they tackled their first epoxy-infused boat hull.

Read More